Method for using mold used for punching spiral hole in sponge inner core

A spiral hole, inner core technology, applied in metal processing and other directions, can solve the problems of human discomfort, breathing resistance, insufficient gas flow, etc., and achieve the effects of avoiding discomfort, increasing humidity, and large airflow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

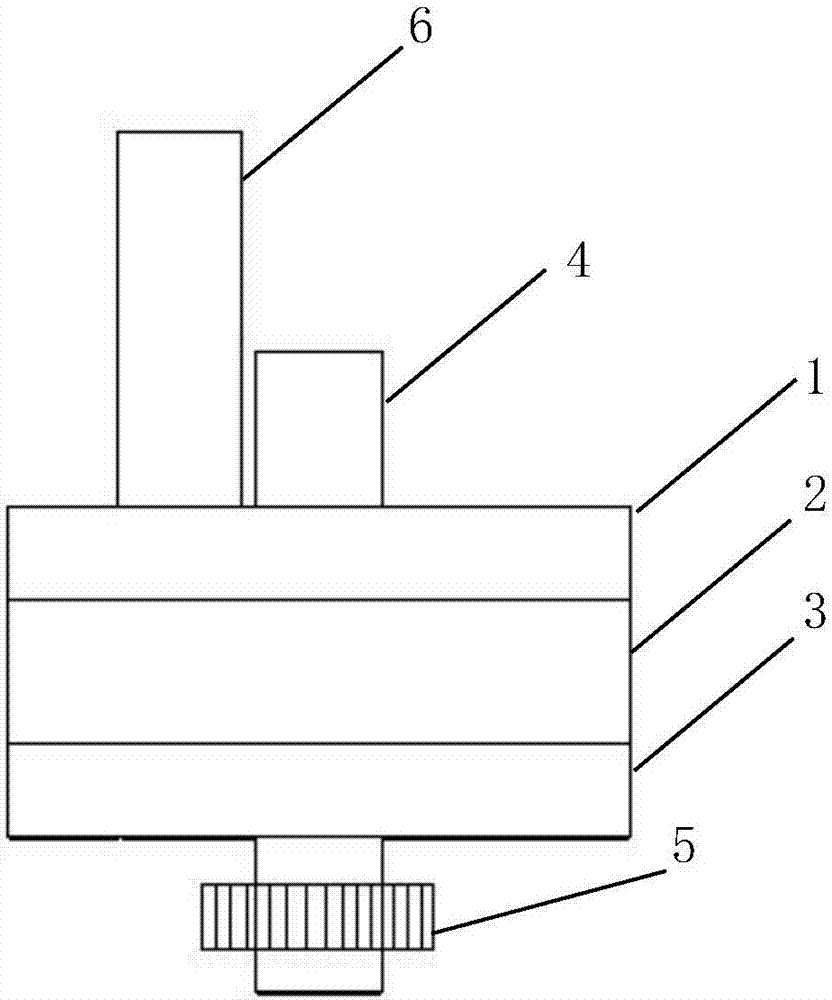

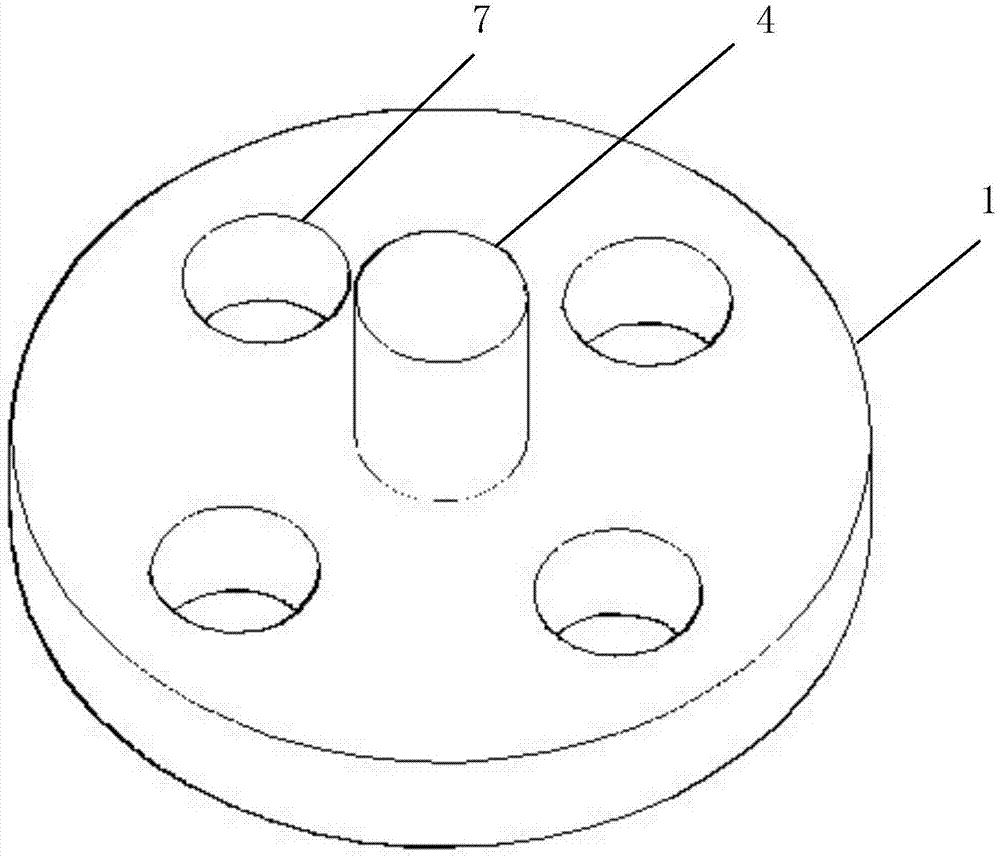

[0033] Example 1: With reference to the drawings, a mold for punching spiral holes in a sponge core includes an upper mold 1, a lower mold 3, and the upper mold 1 and the lower mold 3 are respectively provided with a mold handle 4, a mold hole 7 and The mold surface is provided with positioning pins 8, the lower mold 3, the mold handle 4 is provided with a gear 5, the gear 5 drives the lower mold 3 to rotate a predetermined angle, and the upper mold 1 is provided with a punch hole 7 After closing the mold, the punch 6 punches into the die hole 7 of the lower mold 3.

[0034] In a preferred technical solution, the positioning pin 8 is tapered and has a height of 1-2 mm.

[0035] In a preferred technical solution, the punch 6 is hollow and tubular, and the lower end is provided with a flat knife edge or an inclined knife edge.

[0036] In a preferred technical solution, the gear 5 is connected to the power mechanism, and the gear 5 drives the lower mold 3 to rotate 90°-360°, especiall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com