Double-head edge polishing numerical control stone machine

A stone machine and edging technology, which is applied to grinding frames, machine tools suitable for grinding workpiece edges, stone processing equipment, etc., can solve the problems of clean and orderly workshop environment, unfavorable stacking of semi-finished products, and reduced production efficiency, Achieve the effect of avoiding sharpening knife breakage, improving processing efficiency and product accuracy, and solving dynamic balance problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principle of the present invention will be explained below in conjunction with the accompanying drawings.

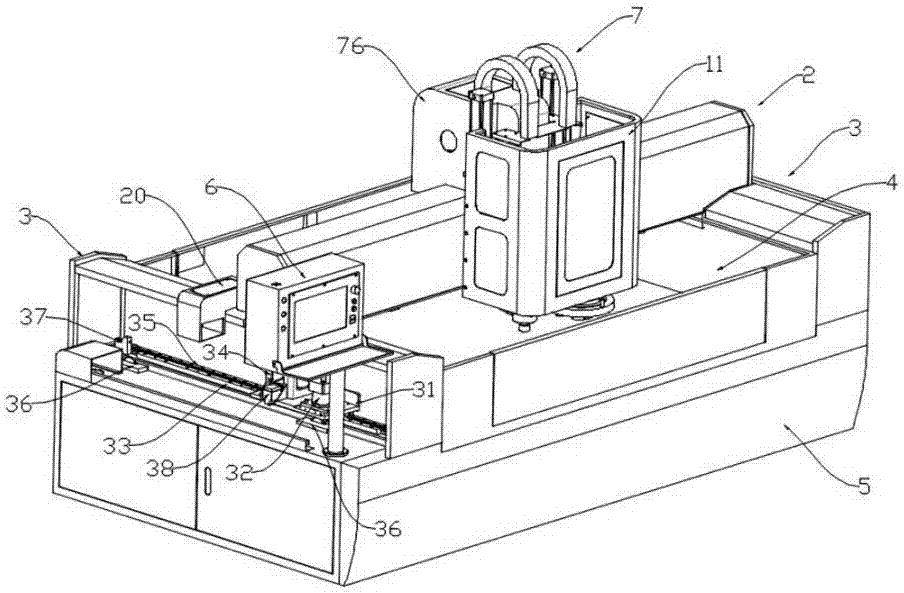

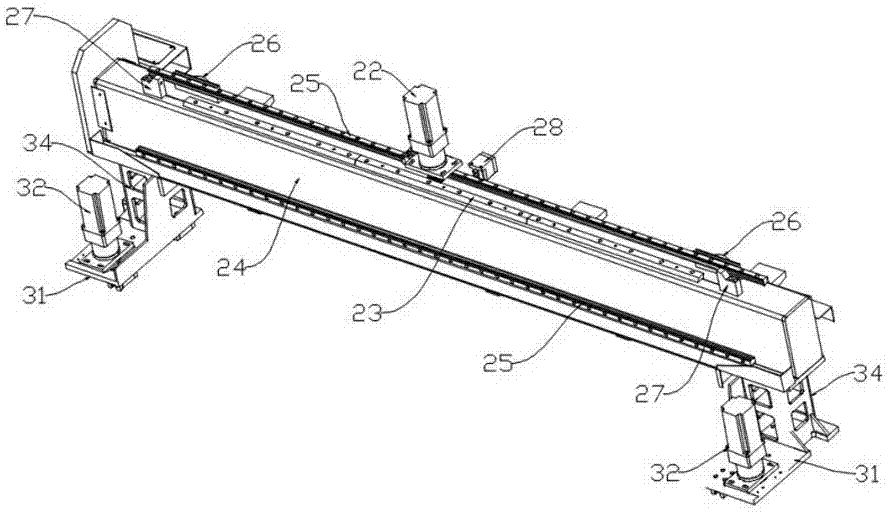

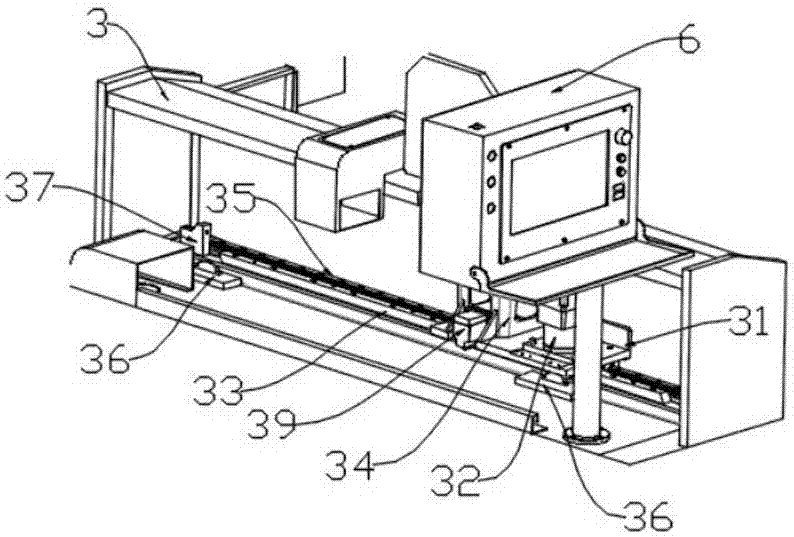

[0030] The double-head edging CNC stone machine of the present invention includes a workbench 4, a bed 5, a head 1 for processing workpieces, a Z-axis mechanism 7 for moving the head 1 up and down, and a Z-axis mechanism for driving the Z The axis mechanism 7 is an X-axis mechanism 2 that translates left and right, two sets of Y-axis mechanisms 3 installed on the bed 5 for driving the X-axis mechanism 2 to move forward and backward, a workbench 4, a bed 5, and a control panel for performing numerical control operations 6. Combine Figures 4 to 6 , the machine head 1 includes a hole opening mechanism and an edge grinding mechanism arranged vertically side by side; the machine head 1 is equipped with a protective cover 11;

[0031] The opening mechanism includes a vertical water-cooled shaft cylinder 121, a vertically disposed water-cooled shaft drive plate 124...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com