Automatic leveling device and method for forward moving type forklift truck

An automatic leveling and forklift technology, applied in the direction of lifting devices, etc., can solve problems such as inconsistent judgment habits and poor adaptability, and achieve the effect of simple control logic, simplified operation, simple control method and logic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below through specific embodiments.

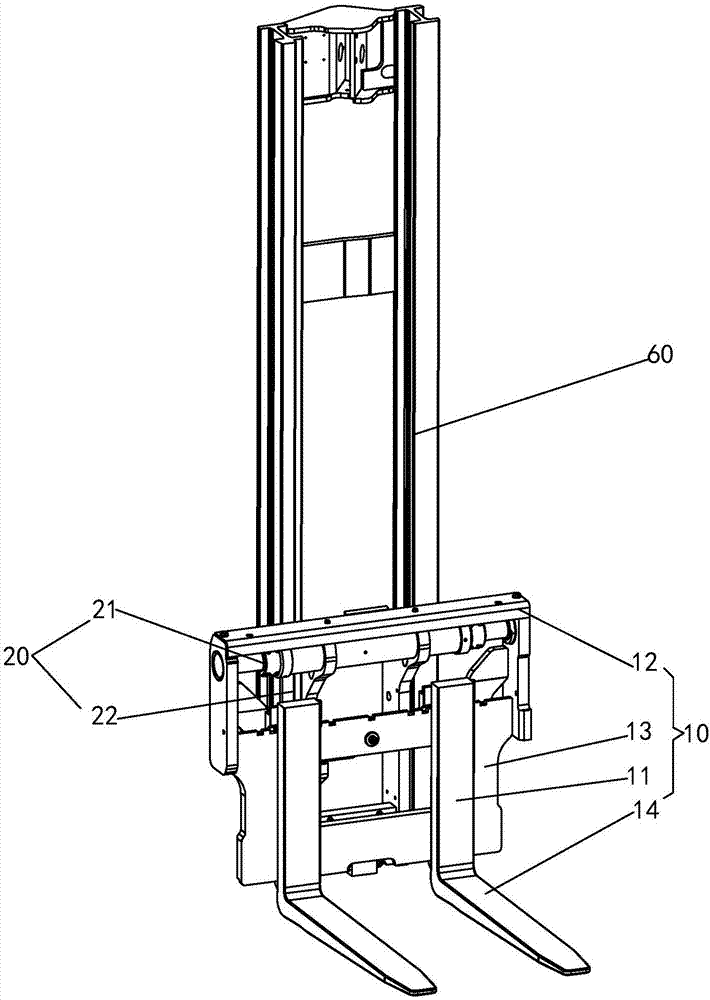

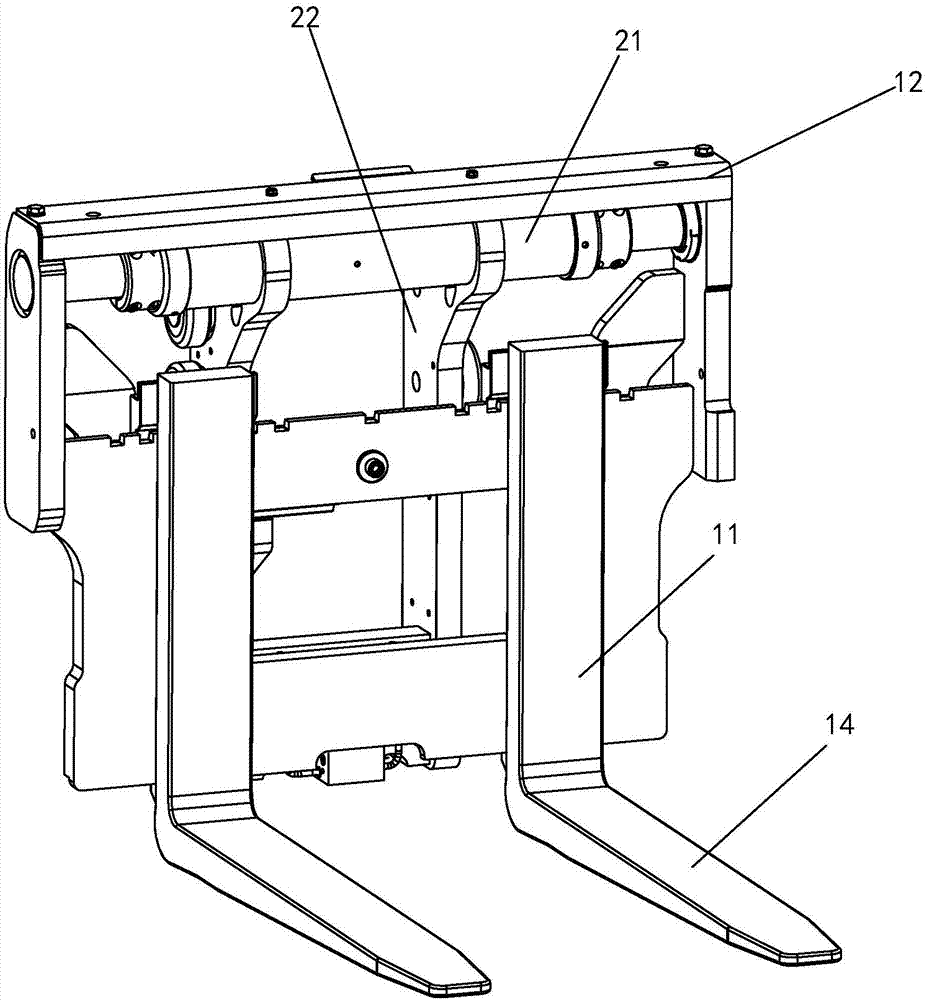

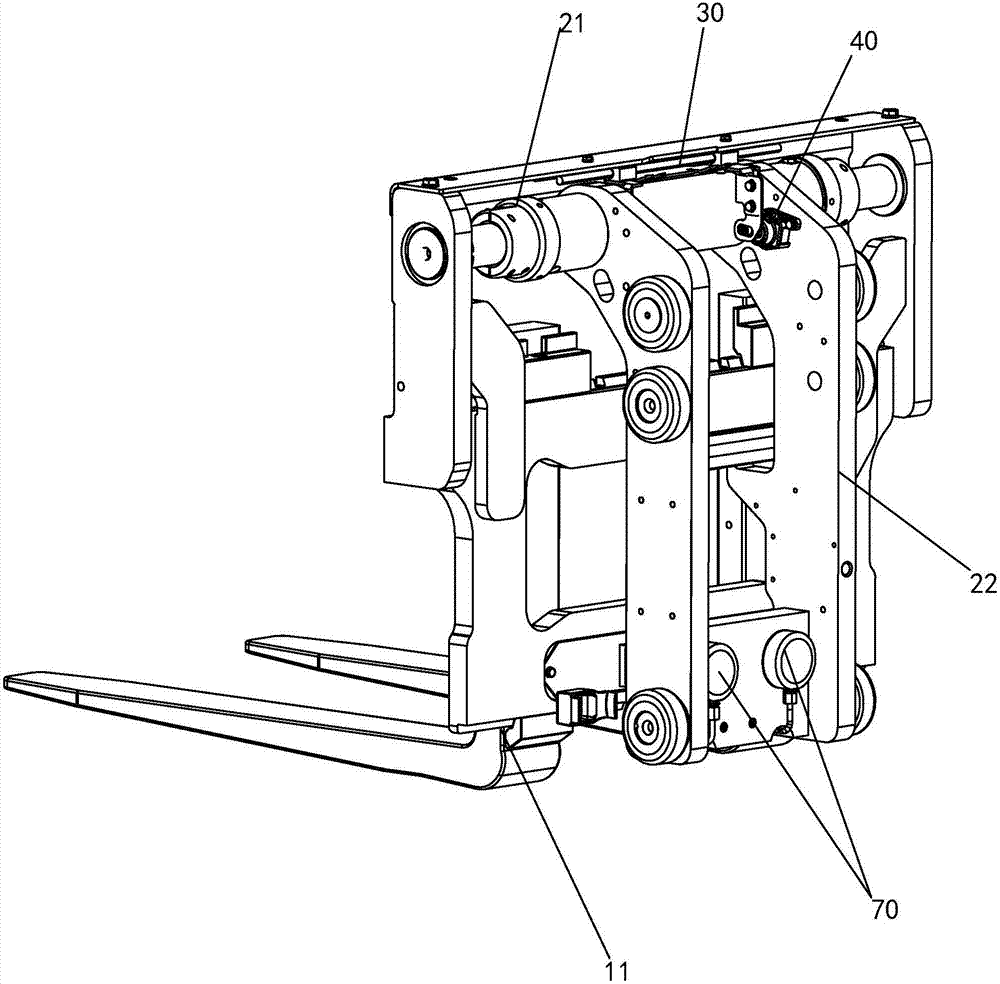

[0042] refer to Figure 1 to Figure 9 , an automatic leveling device for a reach truck, installed between a fork frame 10 and a side shifter assembly 20, including a transmission mechanism 30, an angle sensor 40, a tilt cylinder 70 and a controller 50. The pallet fork frame 10 includes a connecting plate 13 , a pallet fork 11 and a cover plate 12 , and the cover plate 12 and the pallet fork 11 are fixed on the connecting plate 13 . The cover plate 12 can also be other structures, such as a shelf, which can be fixed on the top of the connecting plate 13 . The pallet fork 11 is L-shaped with a horizontal section 14 . The sideshifter assembly 20 includes a sideshift cylinder 21 and a lifting frame, and the lifting frame includes two parallel lifting plates 22. The plate 13 is rotatably connected, and the lateral movement cylinder 21 can drive the fork frame 10 to move laterally relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com