Water conservancy project food grade steel wire rope surface grease, its preparation method and application

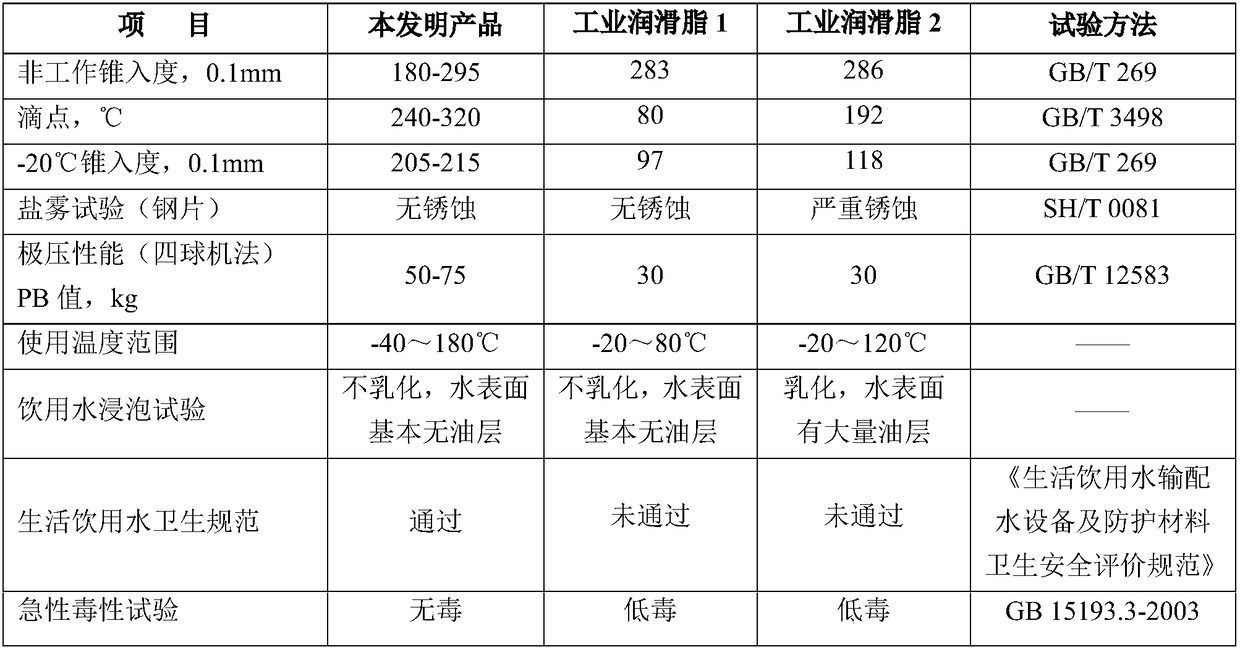

A technology for water conservancy projects and steel wire ropes, applied in the field of food-grade grease, can solve problems such as water pollution, and achieve the effects of safe lubrication, less oil splash, and good anti-wear properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

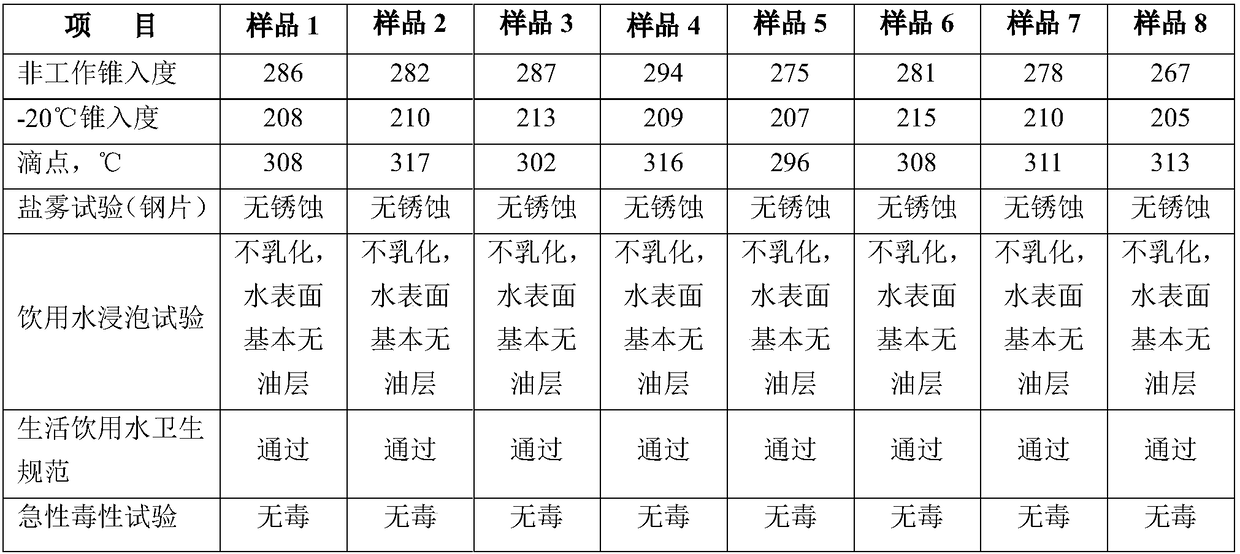

Examples

example 1

[0024] A food-grade lubricating grease for steel wire ropes in water conservancy projects, which is composed of the following raw materials: base oil: 91% and thickener: 9%; plus 5% of the total weight of base oil and thickener; antirust agent;

[0025] The base oil is food-grade synthetic oil, and its kinematic viscosity at 100°C is 10mm 2 / s; the thickener is composed of stearic acid, benzoic acid, and aluminum isopropoxide, and its molar ratio is 1:1.2:1.3; the organoaluminum is aluminum isopropoxide; the rust inhibitor is sulfonic acid Salt.

[0026] Its preparation method comprises the following steps:

[0027] 1) Add 150 grams of stearic acid and 77 grams of benzoic acid to 2000 grams of food-grade synthetic oil (ν 100 =10), heated to 60°C, added 140 grams of aluminum isopropoxide, raised to 80°C, and reacted for 1 hour;

[0028] 2) Continue heating the material after the composite reaction in step 1) to 100°C, add 35 grams of tap water, and keep the temperature const...

example 2

[0033] A food-grade lubricating grease for steel wire ropes in water conservancy projects, which is composed of the following raw materials: base oil: 88% and thickener: 12%; plus 0.5% of the total weight of base oil and thickener; antirust agent;

[0034] The base oil is food-grade synthetic oil, and its kinematic viscosity at 100°C is 10mm 2 / s; the thickener is composed of lauryl hydroxystearic acid, benzoic acid, and aluminum isopropoxide, and its molar ratio is 1:1.2:1.3; the organoaluminum is aluminum isopropoxide; the rust inhibitor For imidazoline.

[0035] Its preparation method comprises the following steps:

[0036] 1) Add 150 grams of lauryl hydroxystearic acid and 77 grams of benzoic acid to 1165 grams of food-grade synthetic oil (ν 100 =10), heated to 60°C, added 140 grams of aluminum isopropoxide, raised to 80°C, and reacted for 1 hour;

[0037] 2) Continue to heat up the material after the composite reaction in step 1) to 100° C., add 35 grams of tap water, ...

example 3

[0042] A food-grade lubricating grease for steel wire ropes in water conservancy projects, which is composed of the following raw materials: base oil: 94% and thickener: 6%; plus 5% of the total weight of base oil and thickener; antirust agent;

[0043] The base oil is food-grade mineral oil, and the kinematic viscosity of the base oil at 100°C is 40mm 2 / s; the thickener is composed of stearic acid, benzoic acid, and aluminum isopropoxide, and its molar ratio is 1:1.2:1.3; the organoaluminum is aluminum isopropoxide; the rust inhibitor is sulfonic acid Salt.

[0044] Its preparation method comprises the following steps:

[0045] 1) Add 150 grams of stearic acid and 77 grams of benzoic acid to 3057 grams of food grade mineral oil (ν 100 =40), heated to 60°C, added 140 grams of aluminum isopropoxide, raised to 80°C, and reacted for 1 hour;

[0046] 2) Continue to heat up the material after the composite reaction in step 1) to 100° C., add 35 grams of tap water, and keep the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com