Cardan shaft assembly and high-frequency impact screw drilling tool using the cardan shaft assembly

A screw drilling tool and high-frequency impact technology, which is applied in the direction of drill pipe, drill pipe, drill bit, etc., can solve the problems of cardan shaft assembly fatigue fracture, slipping, and low life of the whole machine, so as to reduce adverse effects and improve structural strength. Good, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

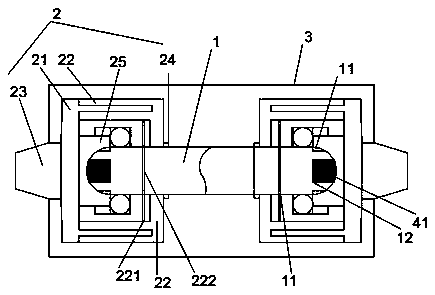

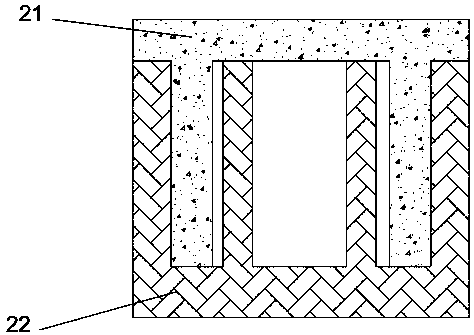

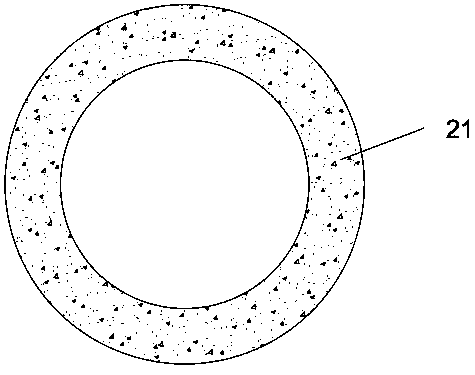

[0035] see figure 1 , the present embodiment provides a cardan shaft assembly, the cardan shaft assembly includes a cardan shaft 1, the two ends of the cardan shaft 1 are connected with outer joints 2, and the outside of the outer joint 2 The rotor and the transmission shaft of the screw drilling tool are respectively connected, and the outer casing joint 2 is respectively connected with the cardan shaft through the steel ball in the cage, so as to realize the connection and power transmission with the transmission shaft and the rotor of the screw drilling tool. It is characterized in that The jacket joint 2 includes a jacket joint convex part 21 and a jacket joint concave part 22, the jacket joint convex part 21 is inserted into the jacket joint concave part 22 and is connected with the jacket joint concave part 22 in a gap, and the jacket joint convex part 21 is not connected with the outer casing joint concave portion 22 is provided with a first connecting head 23 for conne...

no. 2 example

[0063] This embodiment provides a high-frequency impact screw drilling tool using the cardan shaft assembly described in the first embodiment.

[0064] see Figure 6 , the high-frequency percussion screw drilling tool includes the cardan shaft assembly described in the first embodiment, and also includes a bypass valve assembly 5, a motor assembly 6, a transmission shaft assembly 7 and a high-frequency percussion drilling tool 8, The bypass valve assembly 5, the motor assembly 6, the cardan shaft assembly, the transmission shaft assembly 7 and the high-frequency percussion drilling tool 8 are connected sequentially from top to bottom.

[0065] The bypass valve assembly 5, the motor assembly 6 and the transmission shaft assembly 7 can all adopt similar structures in the prior art, for example, the patent No. 201410150118.2 patent name is efficient and durable screw drilling tool. The structure described in; the high-frequency percussion drilling tool can adopt the patent No. 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com