A Radial Bearing with Electromagnetic-Static Double Support

A radial bearing and static pressure technology, applied in bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of low load capacity, small torque, wide temperature range, etc., to increase load capacity and stiffness, relieve design restrictions, The effect of improving adjustment ability and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

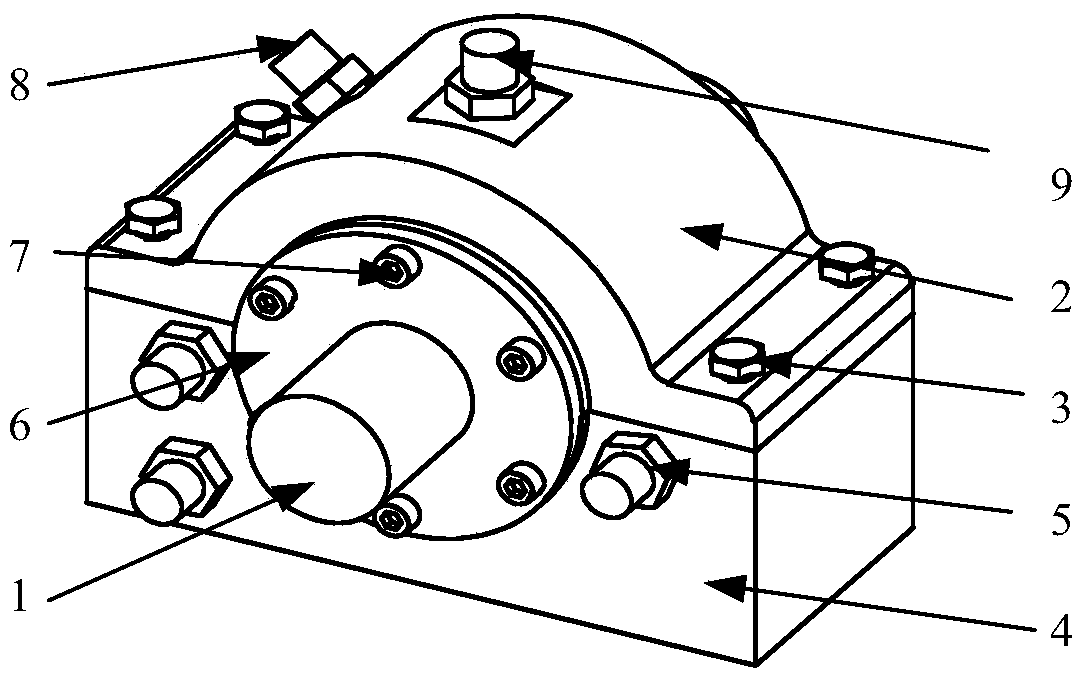

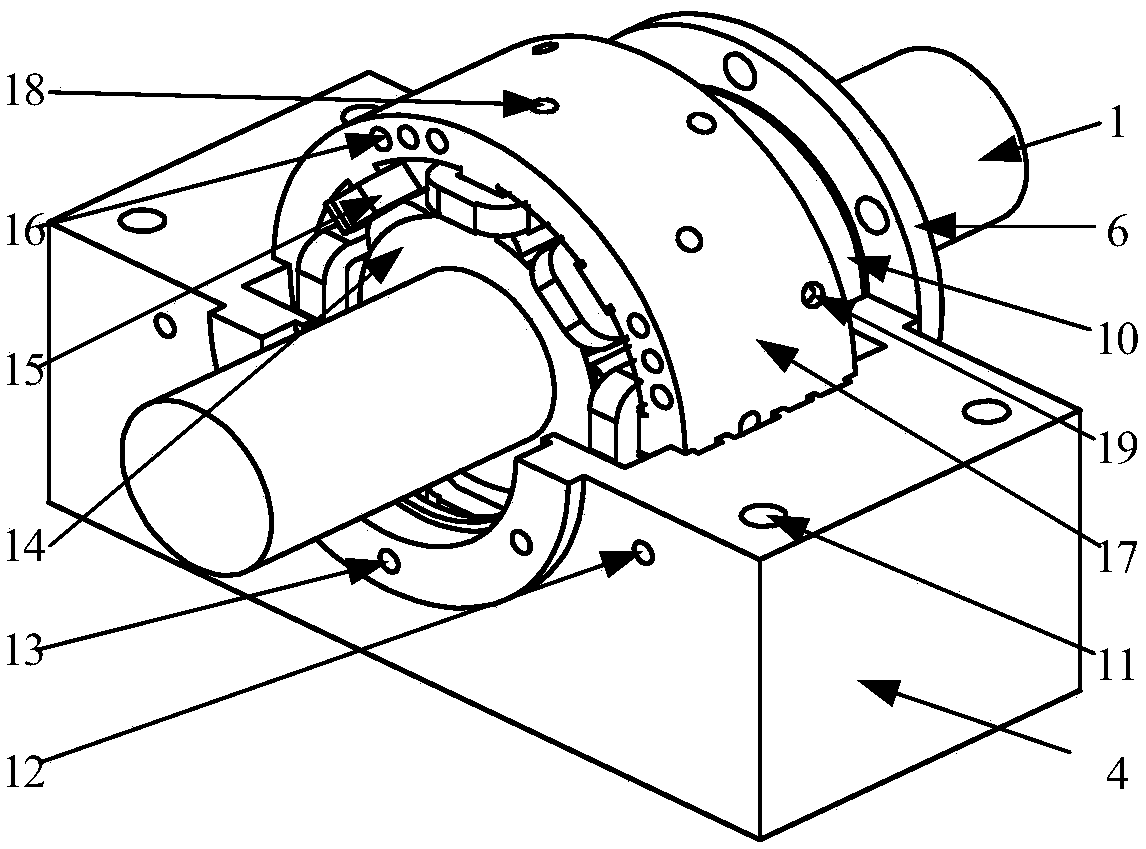

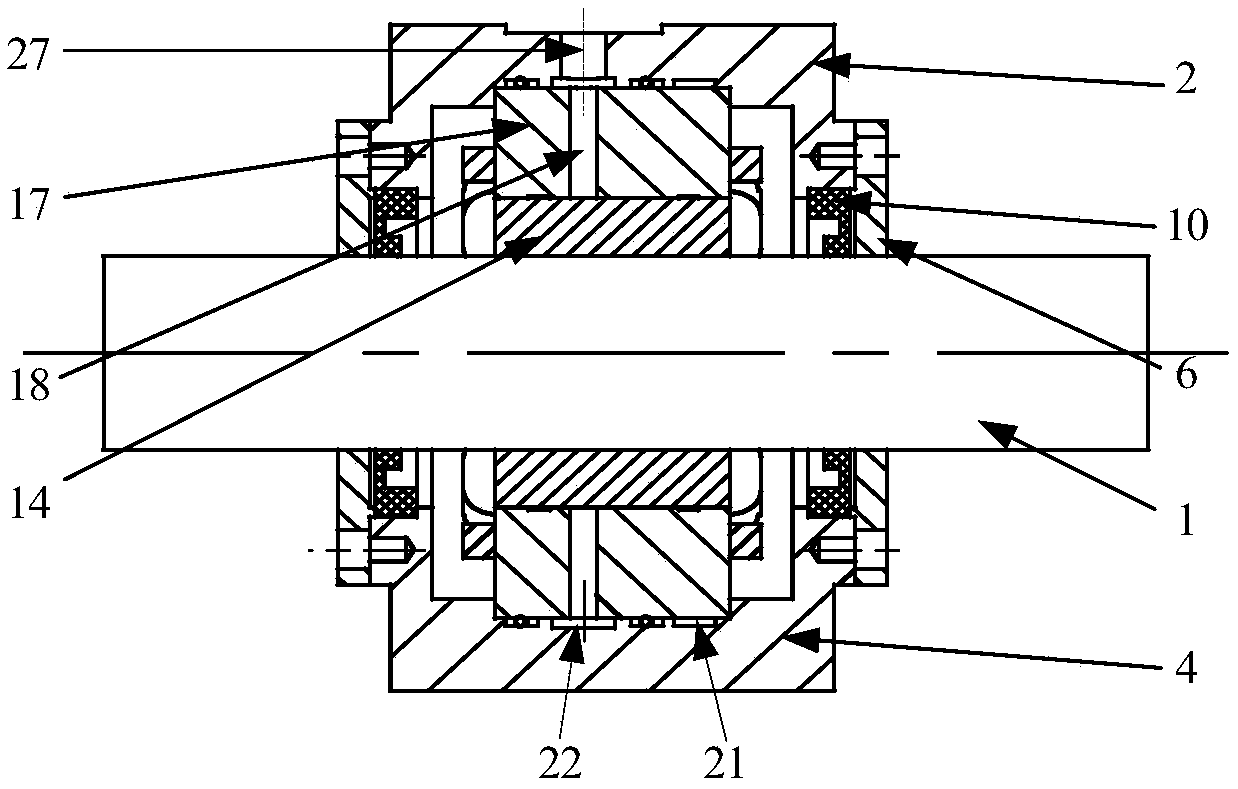

[0017] exist figure 1 , figure 2 , image 3 with Figure 4 In the schematic diagram of the electromagnetic-hydrostatic double-supported radial bearing shown, the middle part of the top surface of the bearing base 4 is provided with a semi-cylindrical upper opening groove with two ends on the two parallel facades of the bearing base, and the middle part of the upper opening groove is set There is an oil inlet groove A22 in the middle, which is a half-interrupted and downwardly recessed strip groove on both sides. Each groove is provided with an oil inlet hole B23, which is connected to the oil inlet hole D12 through the internal oil circuit of the bearing base. , the end of the oil inlet hole located outside the base is provided with a joint A5. In the middle part of the upper opening groove, there is also an overall downward recessed groove parallel to the oil inlet groove, that is, the oil return groove A21. The bearing base is provided with screw holes 11, which corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com