LED wall washing lamp

A technology of LED wall washer and LED light source, which is applied in the field of lighting, can solve the problems of easy entry, glue residue, and easy formation of water vapor, etc., so as to avoid the formation of water vapor, better heat dissipation effect, and eliminate potential hidden dangers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

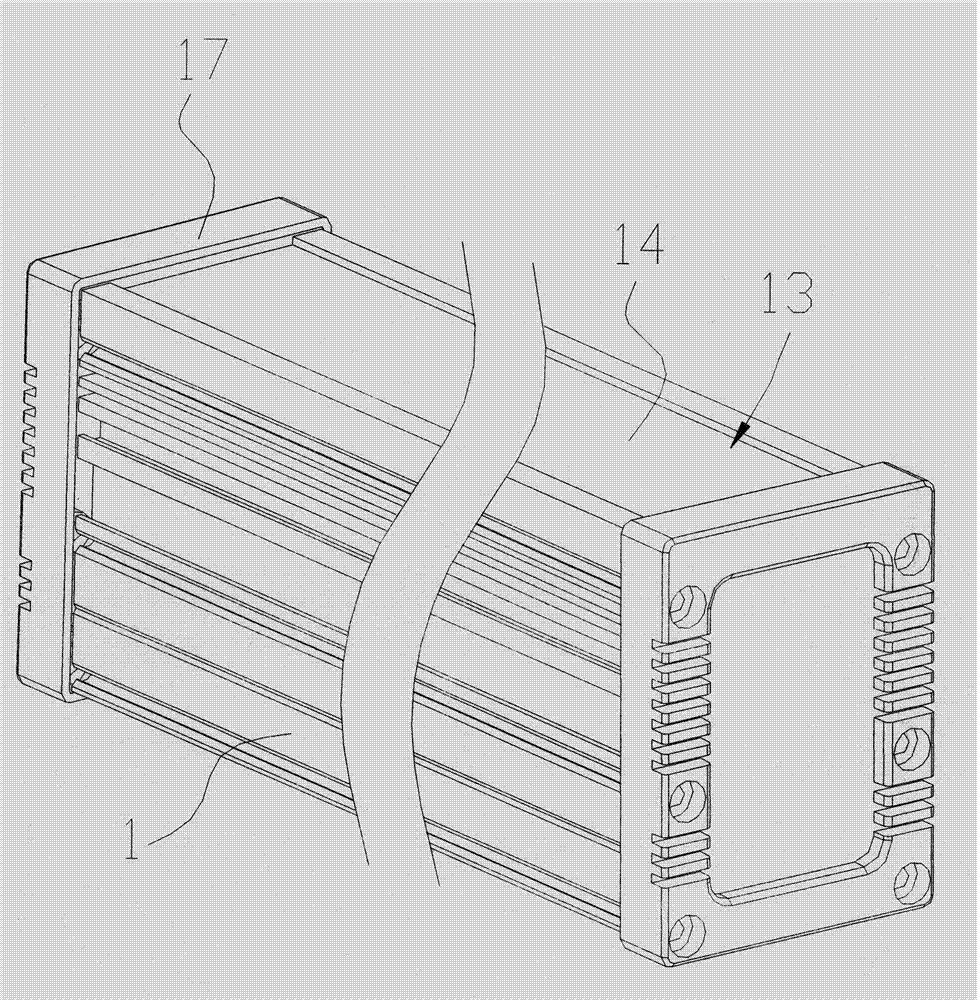

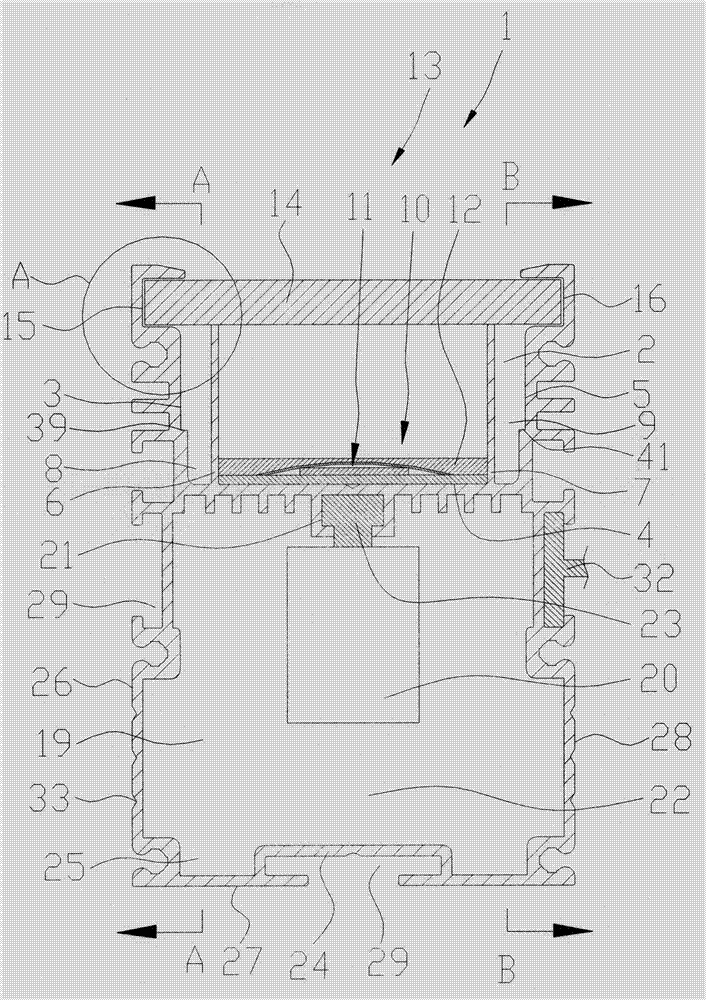

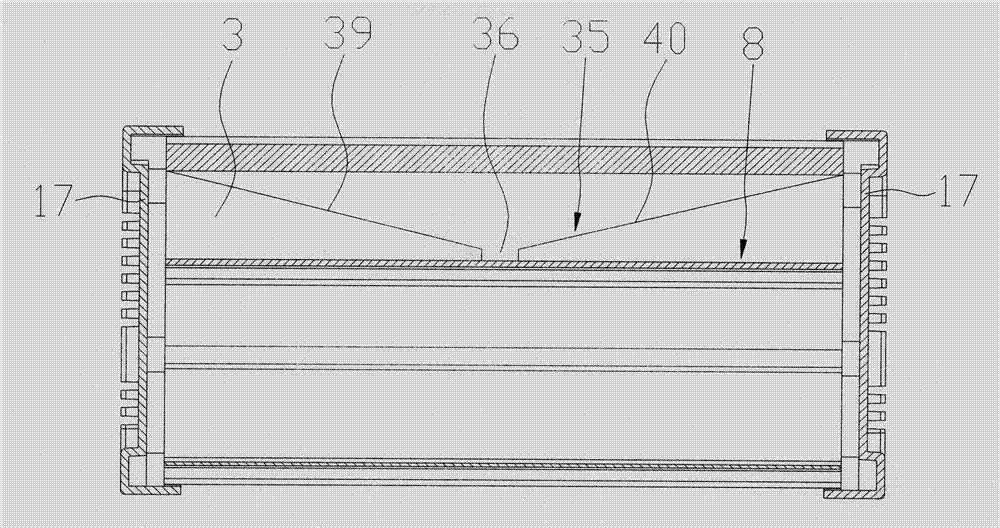

[0024] refer to Figure 1 to Figure 4 , an LED wall washer, comprising a lamp body 1, the lamp body 1 is provided with a first accommodating cavity 2 along its length direction, and the first accommodating cavity 2 includes a first inner wall 3, a second inner wall connected in sequence The inner wall 4 and the third inner wall 5, the second inner wall 4 extends a first baffle 6 and a second baffle 7, and the first baffle 6 and the second baffle 7 are all along the lamp body 1 The length direction of the lamp body 1 is set between the first baffle plate 6 and the first inner wall 3 to form a first drainage groove 8 for draining water to the outside, and the first inner wall 3 is provided with a The first guide slope 35 arranged in the direction, the first guide slope 35 is provided with a first injection port 36, and the first injection port 36 communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com