Dry-wet combined dual-cooling multi-condition cross-flow closed cooling tower and regulating method for running mode of cooling tower

A closed cooling tower, dual cooling technology, applied in the direction of water shower cooler, direct contact heat exchanger, heat exchanger type, etc., can solve the problems of low cooling heat exchange efficiency, large amount of water spray and high energy consumption , to achieve the effect of reducing operating energy consumption, saving water consumption, and improving cooling and heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

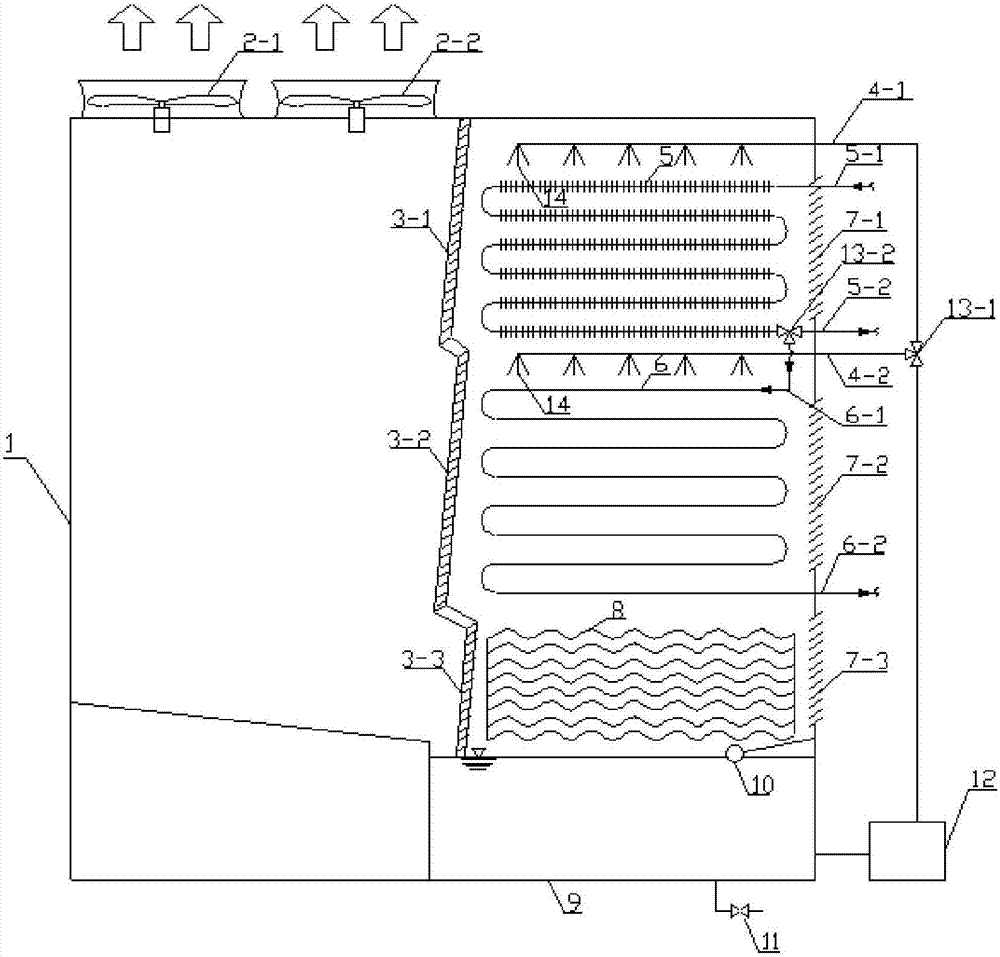

[0028] Such as figure 1 As shown, a dry-wet joint double cooling multi-working condition cross-flow closed cooling tower includes a tower body 1; the cooling tower is also composed of a water absorber, a fan, a finned tube bundle heat exchanger 5, a light tube bundle heat exchanger 6, and a water spray Shower system, air inlet, filler 8, water collection tank 9, water replenishment float valve 10 and drain valve 11; the water absorber is composed of the first water absorber 3-1, the second water absorber 3-2 and the third water absorber 3-3 ; The first water absorber 3-1, the second water absorber 3-2 and the third water absorber 3-3 are installed obliquely inside the tower body 1 from top to bottom, and the inner cavity of the tower body 1 is divided into a left chamber and the two parts of the right chamber; the fan is made up of the first fan 2-1 and the second fan 2-2;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com