Integrated cooling fin, manufacturing mold and manufacturing method for integrated cooling fin

A technology for manufacturing molds and heat sinks, applied in heat exchange equipment, lighting and heating equipment, laminated components, etc., can solve problems affecting heat transfer, low production efficiency, breakage, etc., to improve heat dissipation efficiency, increase production efficiency, The tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

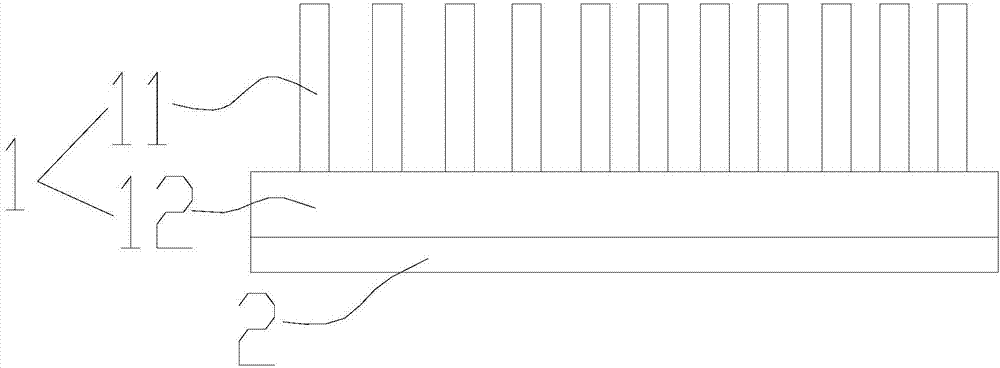

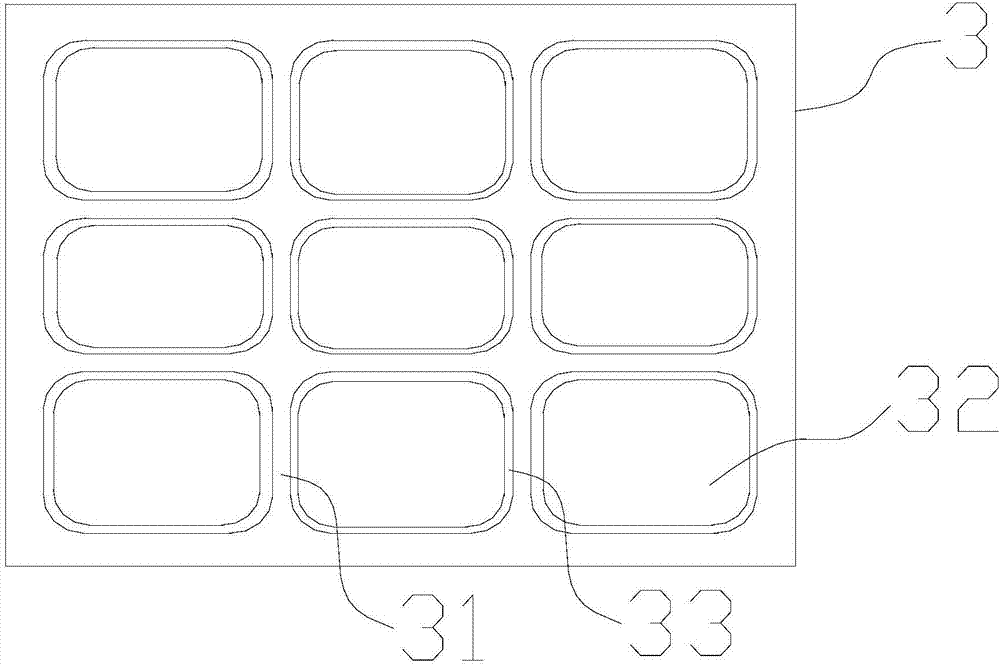

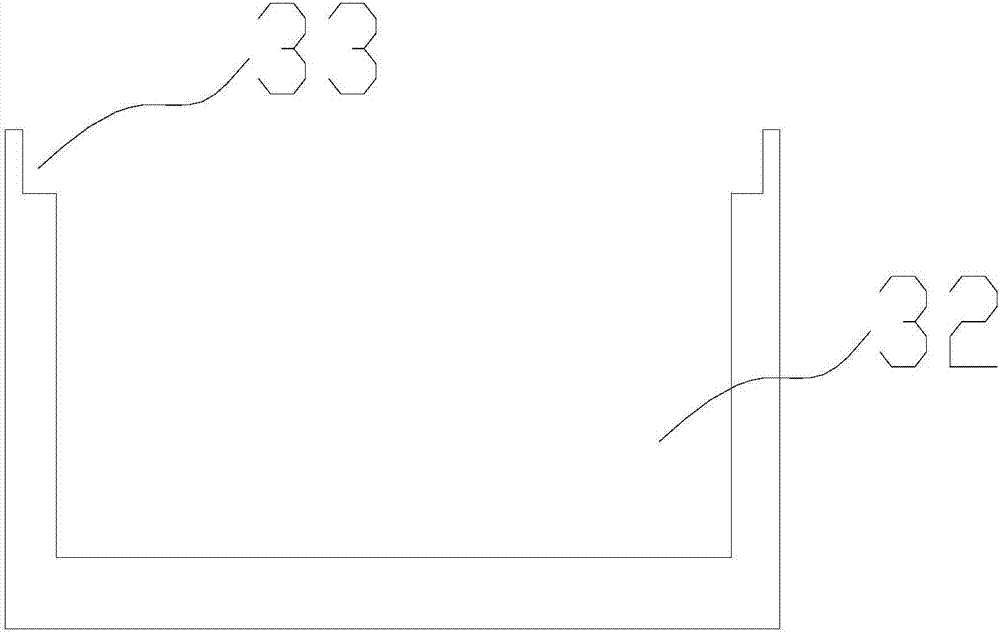

[0023] An embodiment of the present invention provides an integrated heat sink, such as figure 1 As shown, it includes: a heat sink body 1 with heat dissipation fins 11 and a heat dissipation substrate 12 , and the bottom plane of the heat dissipation substrate 12 is integrally formed with a soft heat conduction pad 2 in a thermosetting manner.

[0024] In this embodiment, the soft heat conduction pad adopts heat conduction silica gel, of course, heat conduction silicone grease or heat conduction gel may also be used in other embodiments.

[0025] In order to make the combination of the soft thermal pad and the heat sink body more stable, the heat dissipation substrate can be made of thermal conductive resin or heat-resistant plastic.

[0026] In this embodiment, after the heat sink product is completed, the soft heat conduction pad is solidified in a thermosetting manner, so that after the heat sink product is completed, there is an integrally formed soft heat conduction pad....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com