De-embedding method of small signal measurement

A small signal, measurement technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as excessive de-embedding, and achieve the effects of convenient production, convenient calculation process, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

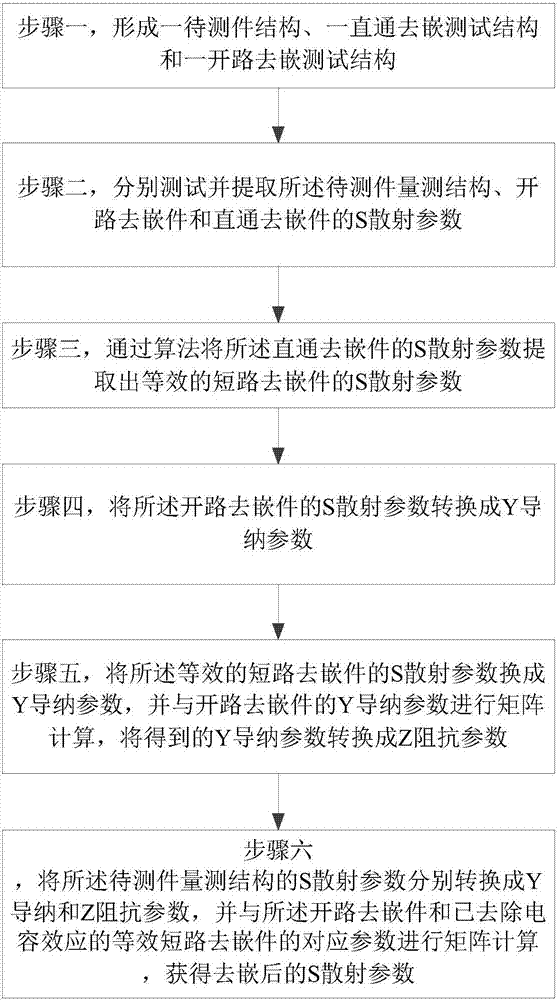

[0035] see figure 1 As shown, a de-embedding method for small signal measurement of the present invention includes the following steps:

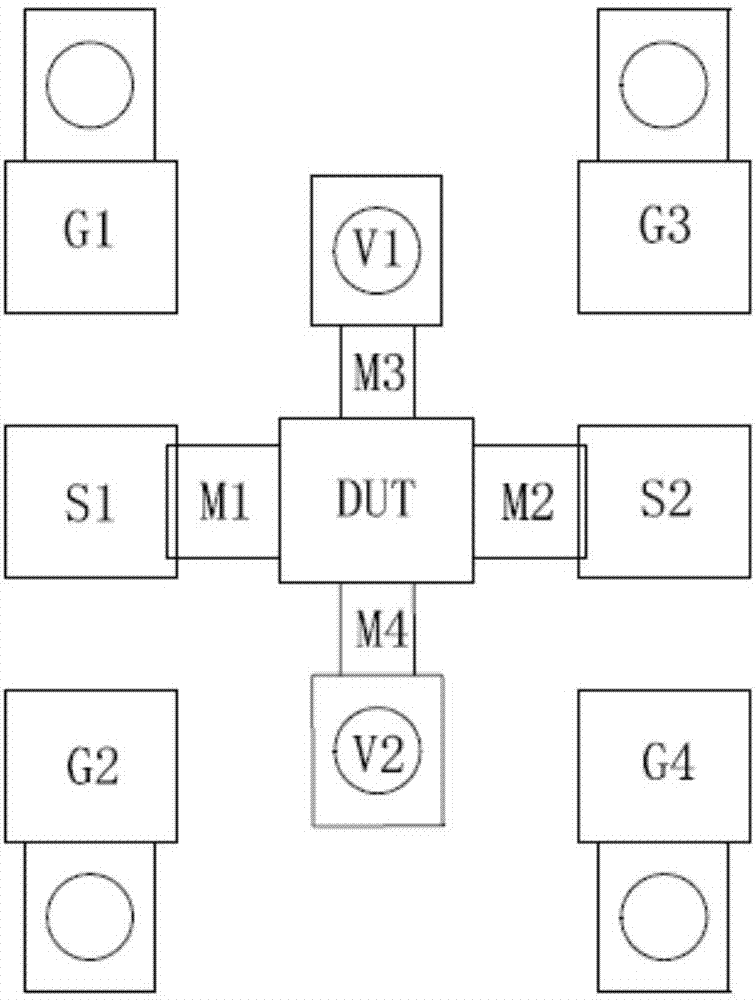

[0036] Step 1, forming a measuring structure of the DUT, a through-cut insert and an open-circuit insert. Specifically, such as figure 2 As shown, the measurement structure of the DUT includes a DUT, a signal input pad S1, a signal output pad S2, a first ground pad G1, a second ground pad G2, a third ground pad plate G3, the fourth ground pad G4, the first ground back hole V1 and the second ground back hole V2, the signal input pad S1 is connected to the input end of the DUT through the wiring metal M1, the signal The output pad S2 is connected to the output end of the DUT through the wiring metal M2, the first ground back hole V1 is connected to the ground end of the DUT under test through the wiring metal M3, and the second ground back hole V1 is connected to the ground terminal of the DUT under test through the wiring metal M3. The ho...

Embodiment 2

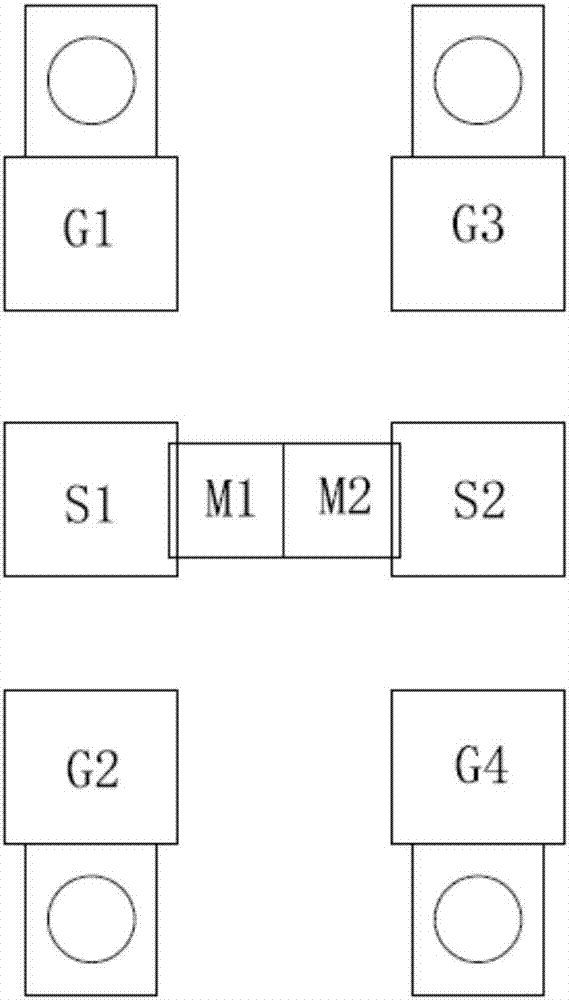

[0054] Step 1, forming a measuring structure of the DUT, a through-cut insert and an open-circuit insert. Specifically, such as figure 2 As shown, the measurement structure of the DUT includes a DUT, a signal input pad S1, a signal output pad S2, a first ground pad G1, a second ground pad G2, a third ground pad plate G3, the fourth ground pad G4, the first ground back hole V1 and the second ground back hole V2, the signal input pad S1 is connected to the input end of the DUT through the wiring metal M1, the signal The output pad S2 is connected to the output end of the DUT through the wiring metal M2, the first ground back hole V1 is connected to the ground end of the DUT under test through the wiring metal M3, and the second ground back hole V1 is connected to the ground terminal of the DUT under test through the wiring metal M3. The hole V2 is connected to the ground terminal of the DUT through the wiring metal M4. Such as image 3 As shown, the straight-through removing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com