Shockproof hammer

A technology of anti-vibration hammer and iron hammer, which is applied in the direction of mechanical vibration attenuation devices, etc., can solve the problems of ineffective reduction of cable vibration, increase of amplitude of anti-vibration hammer, and unstable effectiveness, so as to achieve safe and reliable use, reduce shaking, reduce shaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

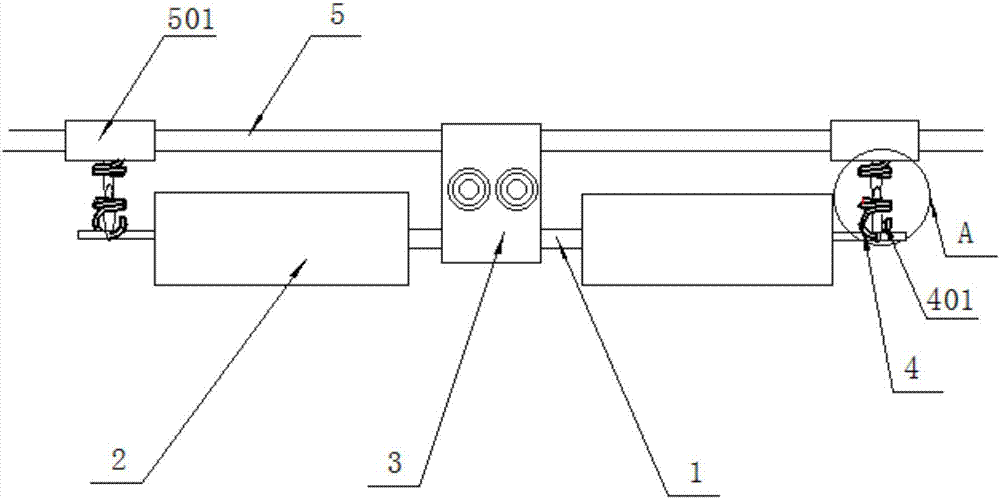

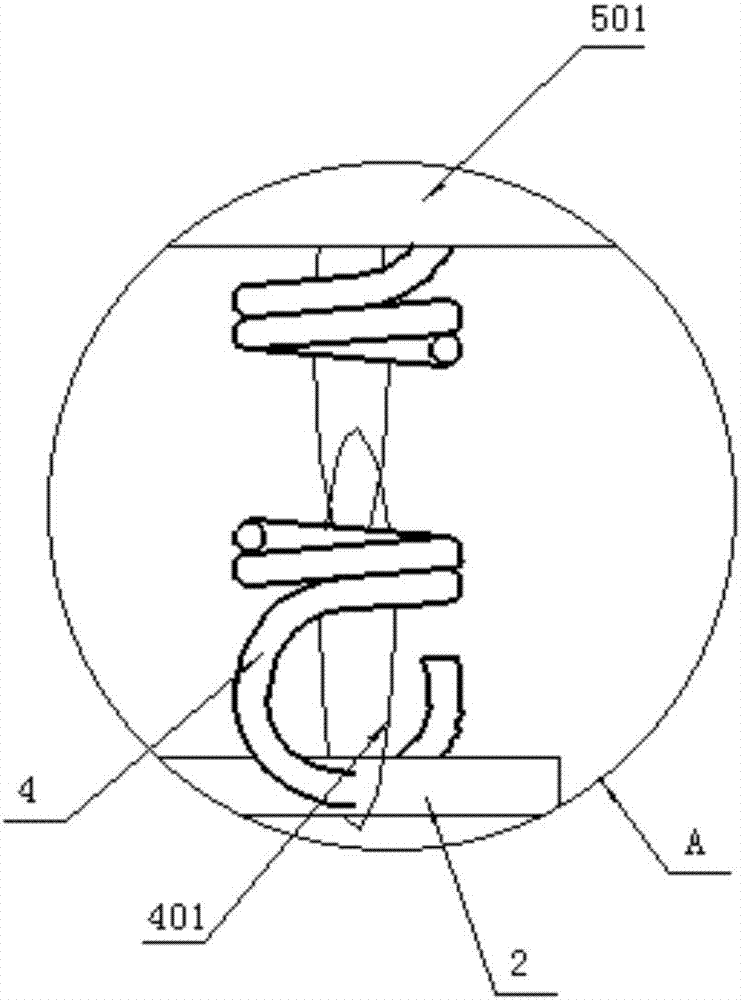

[0011] like Figure 1-2 As shown, a shockproof hammer includes a short steel strand 1 and a cast iron hammer head 2 connected at both ends, a clamping plate 3 is connected to the short steel strand 1, and the ends of the two cast iron hammer heads 2 are connected There is a tension spring 4, the other end of the tension spring 4 is connected with the cable 5, and the inside of the tension spring 4 is provided with two oval pull rings 401 connected together, and the two ends of the pull ring 401 are respectively connected with the cable 5 and the cast iron The hammer head 2 is fixedly connected. In order to facilitate the connection of the pull ring 401 and the tension spring 4 with the cable 5, a connecting pipe 501 for connecting the tension spring 4 and the pull ring 401 is sleeved on the cable 5 corresponding to the upper side of the cast iron hammer head 2 .

[0012] During work, the clamping plate 3 is fixedly connected on the cable 5 earlier, and the connecting pipe 501 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com