Improved stacking machine

A stacker, an improved technology, applied in the stacking of objects, conveyors, de-stacking of objects, etc., can solve the problem of increasing the input cost of packaging equipment, increasing the complexity of the stacker mechanism and production cost, and being unable to empty Box split into single etc. problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

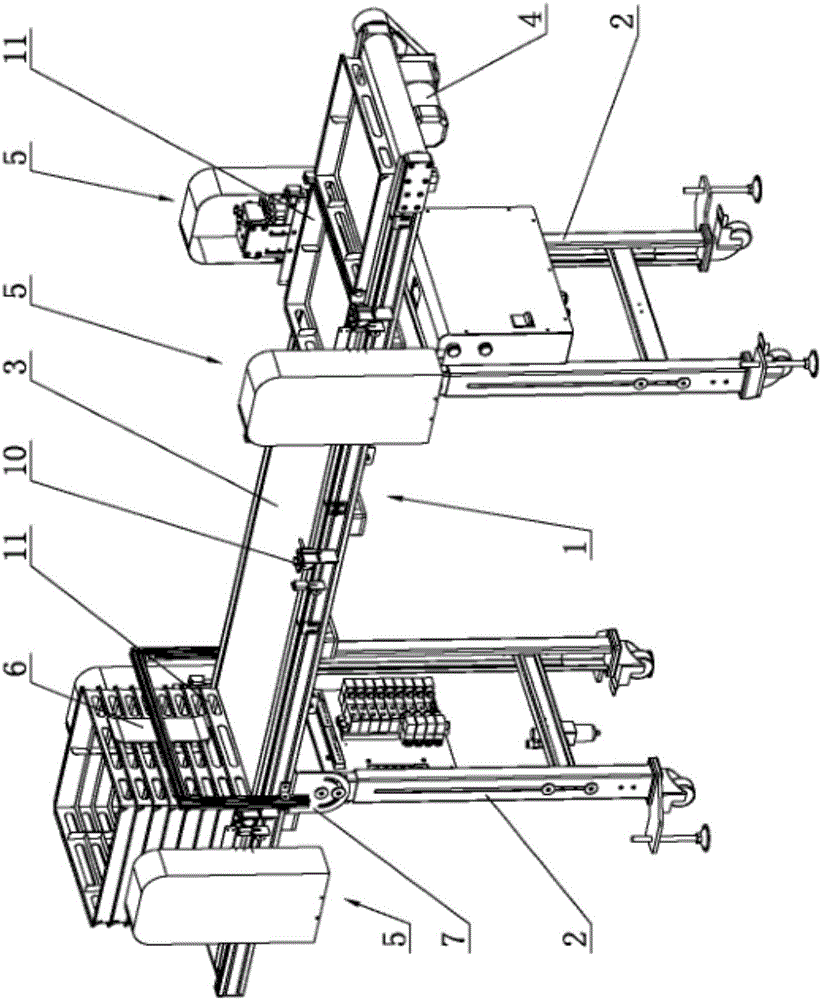

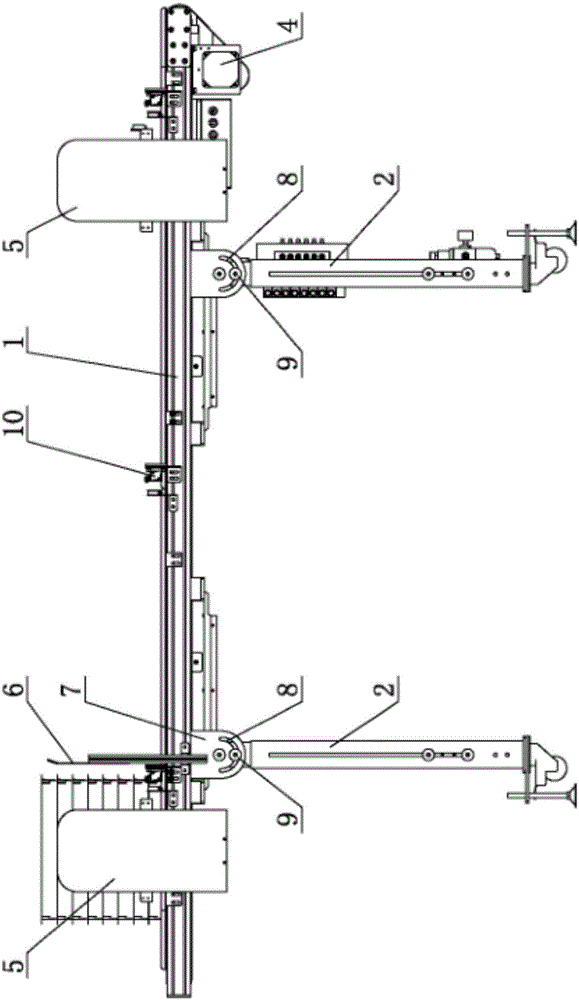

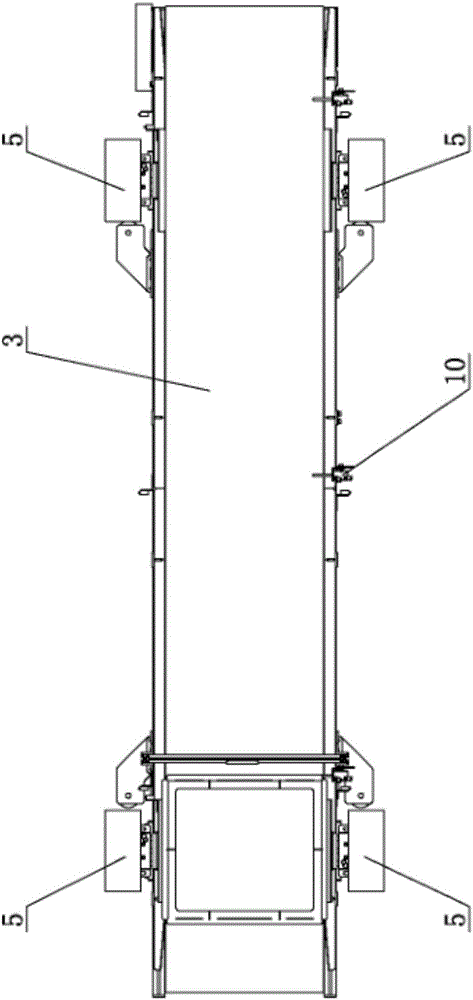

[0023] Such as Figure 1 to Figure 6 As shown, an improved stacker includes a frame 1 and a support foot 2 connected to the frame 1. Both ends of the frame 1 are equipped with rollers, and a conveyor belt 3 is set on the rollers. The frame 1 is equipped with a motor 4 for driving the conveyor belt 3 to run, and both sides of the frame 1 are equipped with a disassembly unit 5, and the disassembly unit 5 is located at the side of the conveyor belt 3.

[0024] In practical application, the improved stacker is located near the manipulator in the factory building, and the empty cargo boxes 11 stacked in a stack are put between the two disassembly units 5, and under the action of the disassembly u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com