Anti-floating device of basement of soft soil foundation and construction process thereof

A soft soil and base technology, applied in the field of building foundations, can solve the problems of small pull-out resistance, large initial displacement, and cracking of basement concrete, and achieve the effects of low cost, convenient construction and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

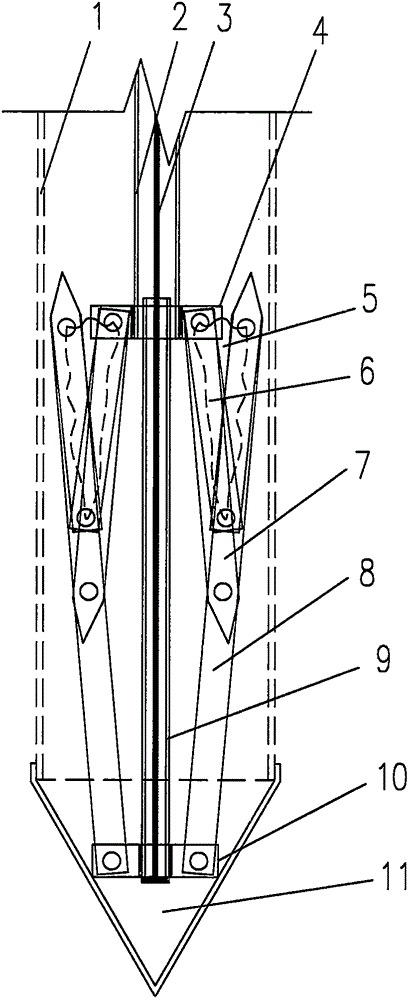

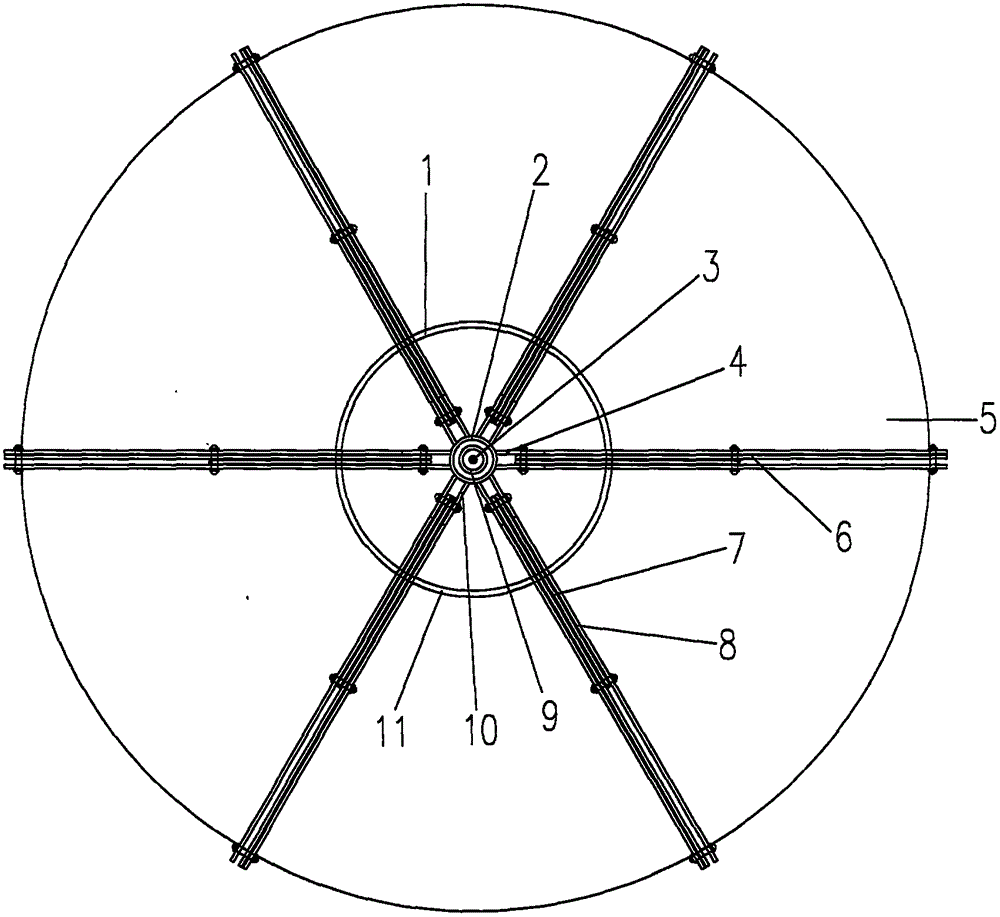

[0015] according to figure 1 and figure 2 , the fabrication process of a typical embodiment of the present invention is as follows:

[0016] 1. Make each part of the device of the present invention, steel casing 1, outer steel round pipe 2, steel strand 3, upper support arm 4, geotextile 5, anchor lock rod 6, anchor arm 7, anchor wing 8, inner steel circle Pipe 9, lower support arm 10, spud shoe 11.

[0017] ②Connect the anchor arm 7 to the anchor wing 8, the lower brace arm 10 to the anchor wing 8, the upper brace arm 4 to the anchor arm 7, and the anchor lock bar 6. A geotextile 5 is laid between each anchor lock bar 6, and the outer steel The round pipe 2 is welded to the upper support arm 4, the inner steel round pipe 9 is welded to the lower support arm 10, and placed inside the outer steel round pipe 2, the steel strand 3 is connected to the inner steel round pipe 9, and extends through the outer round pipe 2 To the outside, the entire device surface is coated with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com