Beam structure and drilling rig

A beam and drilling rig technology, which is applied to earth-moving drilling, wellbore/well components, etc., can solve the problems of unfavorable lightweight design of the upper beam structure of the outer arm, weak rigidity and strength of the upper beam of the outer arm, and heavy weight of the upper beam structure. , to achieve the effect of lightweight design, reasonable stiffness and strength matching, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

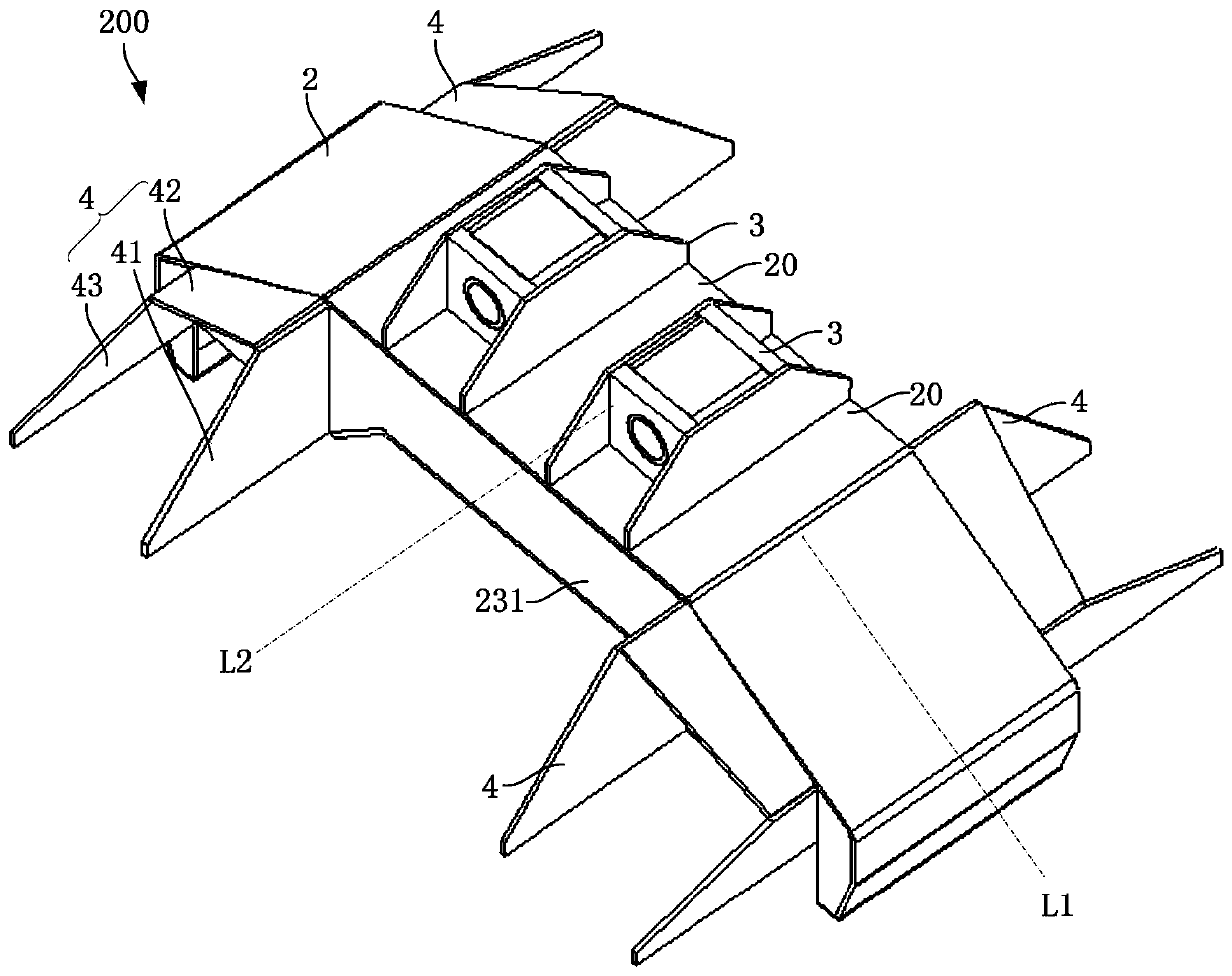

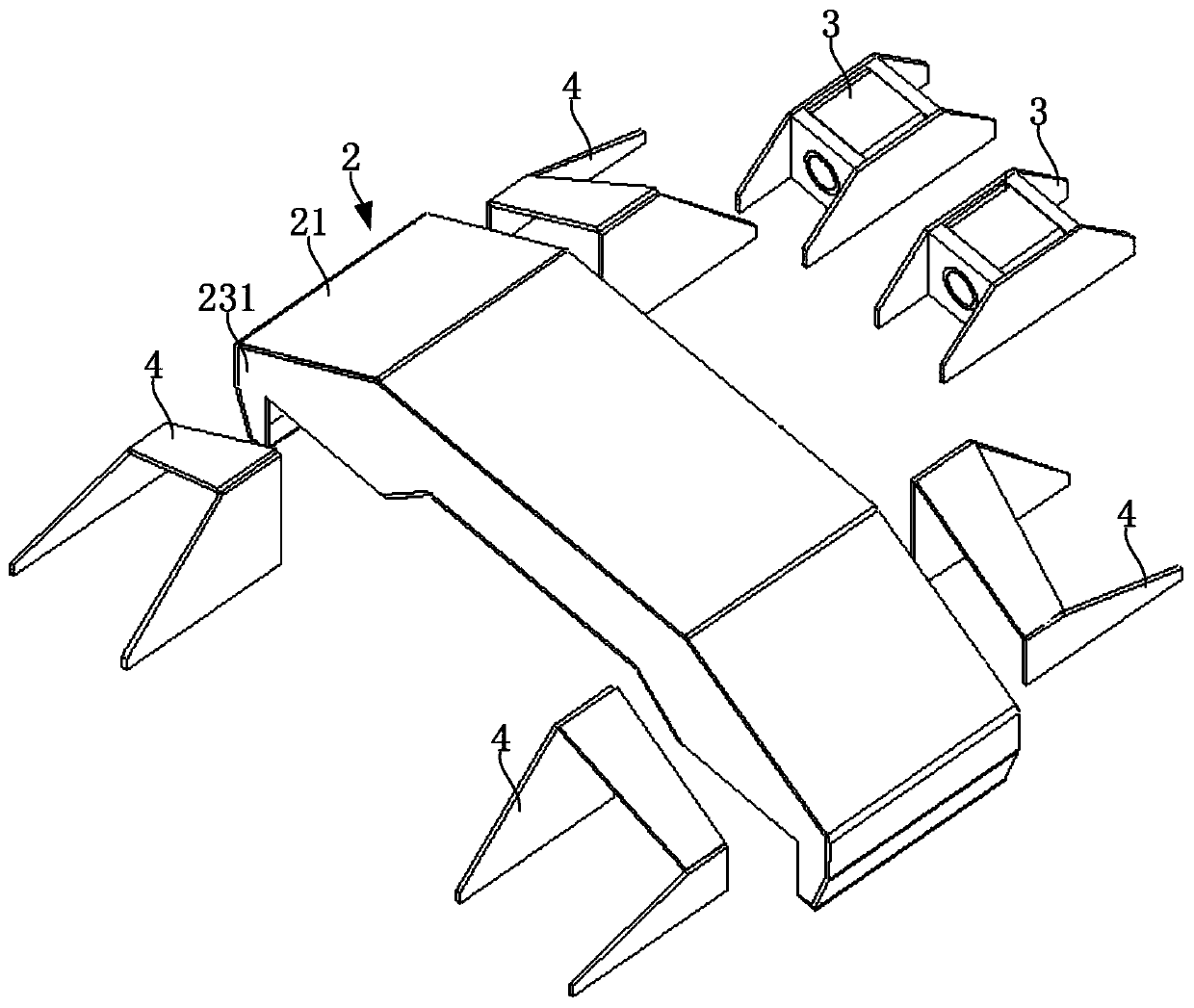

[0030] Combine below Figure 1 to Figure 7 The technical solution provided by the present invention is described in more detail.

[0031] see figure 1 , the embodiment of the present invention provides a beam structure 200 for installation on the outer arm 100 of the drilling rig. The outer arm 100 of the drilling rig can be provided with a plurality of beam structures, and the beam structure 200 provided by the embodiment of the present invention is especially suitable as an upper beam structure, which is arranged on the middle and upper part of the outer wall 1 of the drilling rig. see figure 2 , the beam structure 200 includes a mounting portion 2 and a force receiving portion 3 , the mounting portion 2 is configured to protrude toward a direction away from the outer arm 100 of the drilling rig, and the force receiving portion 3 is mounted on the raised surface 20 of the mounting portion 2 .

[0032] The mounting part 2 is protruding, specifically, it may be an arched p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com