Inclined disc type Stirling engine

A Stirling engine and swash plate technology, applied in hot gas variable displacement engine devices, machines/engines, mechanical equipment, etc., can solve the complex structure of the swash plate, which affects the normal use of the Stirling engine, and the sealing structure of the piston rod Larger damage and other problems, to achieve the effect of simple structure, low cost, convenient processing, installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

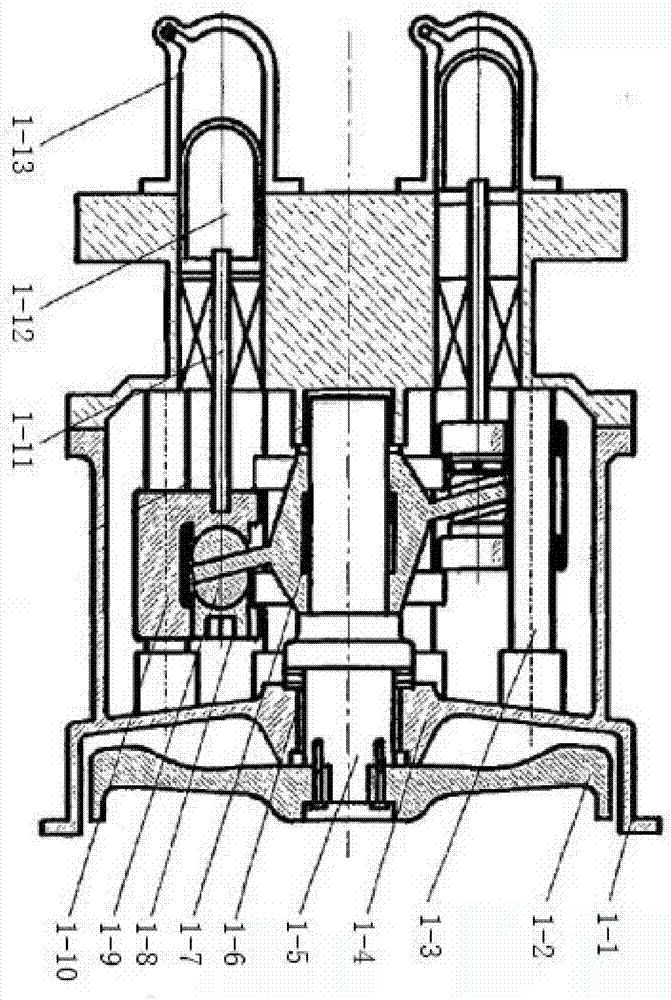

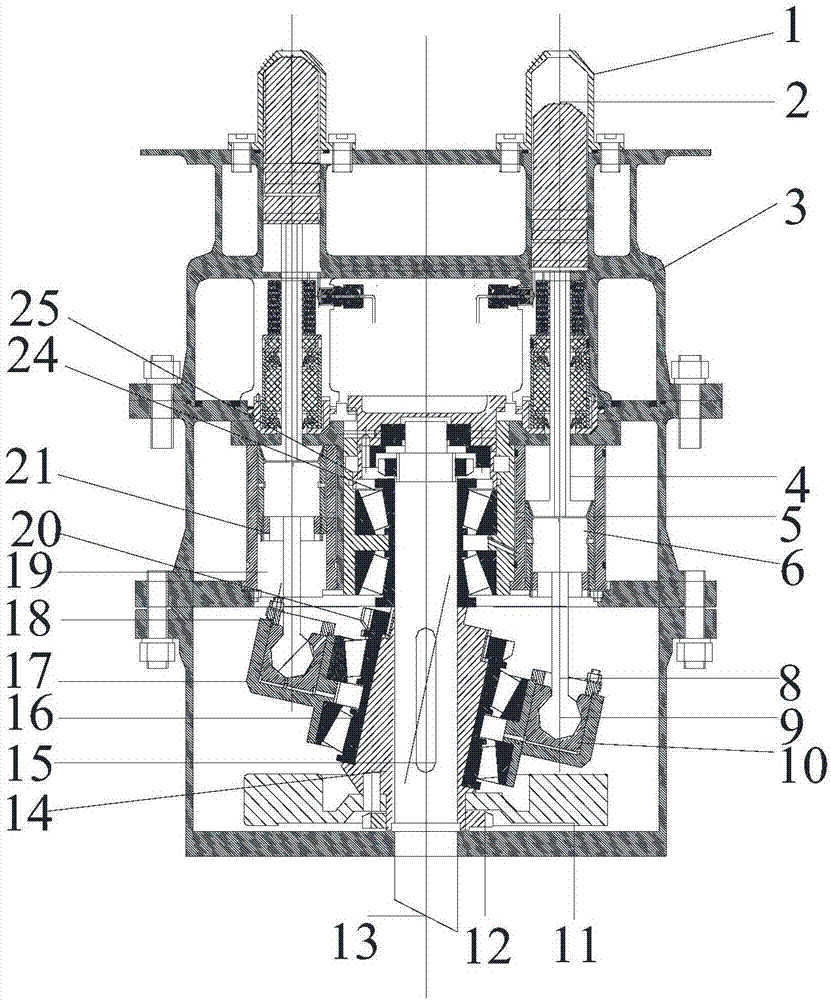

[0029] Such as figure 2 Shown, a kind of swash plate type Stirling engine comprises engine casing 3, cylinder 1, piston 2, piston rod 4, output main shaft 13 and swash plate transmission device, and this swash plate transmission device is used for piston 2 The linear motion is converted into a rotary motion of the output spindle 13 . The Stirling engine consists of four double-acting piston systems and their matching cylinders 1, which are all installed in the engine casing, and the cooler and regenerator connected to it are not connected to the swash plate transmission. The swash plate transmission includes a slide tube 19 and a swash plate mechanism, and one end of the piston rod 4 is shaped on a slide block 5, and the slide block 5 can move up and down in the slide tube 19.

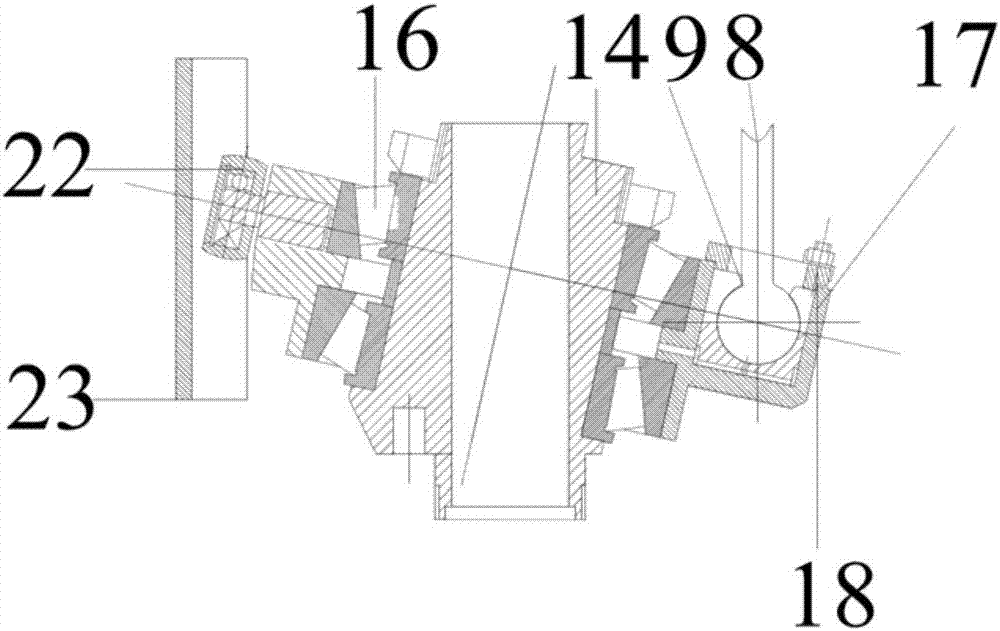

[0030] The swash plate mechanism includes a swash plate 17 and a slant sleeve 14 sleeved on the output spindle 13. The swash plate 17 is mounted on the outer circumference of the slant sleeve 14 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com