Waterproof ink for corrugated carton printing and preparation method thereof

A corrugated box and ink technology is applied in the field of waterproof ink for corrugated box printing and its preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

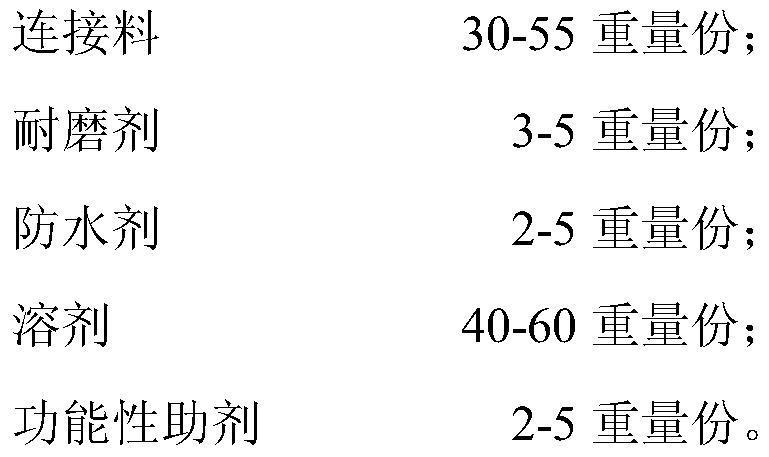

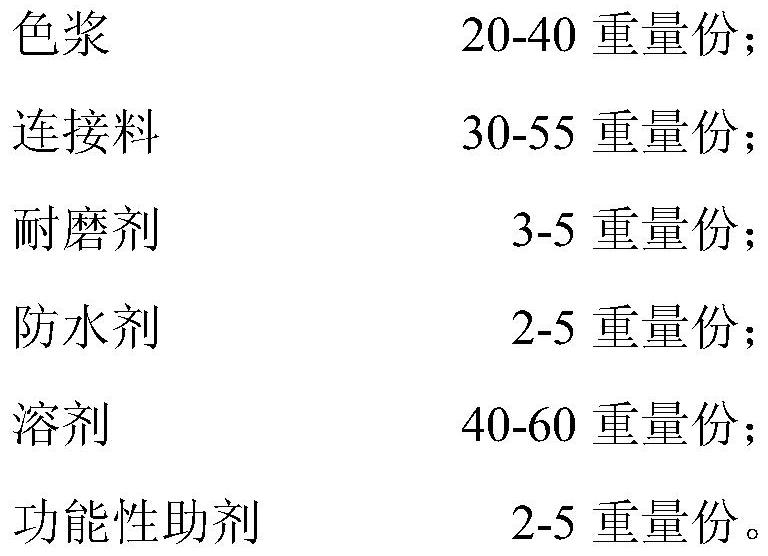

[0045] A waterproof ink for corrugated box printing, consisting of the following components:

[0046]

[0047] Specifically, the color paste is one or more mixtures of iron oxide, carbon black, pigment or / and color lake; the iron oxide is black iron oxide, red iron oxide, yellow iron oxide, brown iron oxide or One of the purple iron oxides.

[0048] Specifically, the binder is one or more mixtures of shellac, gum arabic, acrylic resin, vinyl resin or / and rosin resin; the shellac is bleached shellac, shellac sheet or decolorized shellac sheet kind of.

[0049] Specifically, the waterproofing agent is one of palmitic acid, stearic acid, arachidic acid or lignin acid.

[0050] Specifically, the solvent is one of isopropanol, ethyl acetate, ether...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com