Cold water recycling device, shower system and cold water recycling method

A technology of cold water recovery and water inlet valve, applied in heating devices, solar thermal devices, lighting and heating equipment, etc., can solve the problems of space occupation, product cost increase, waste, etc., to achieve convenient temperature adjustment, stable water supply capacity, The effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

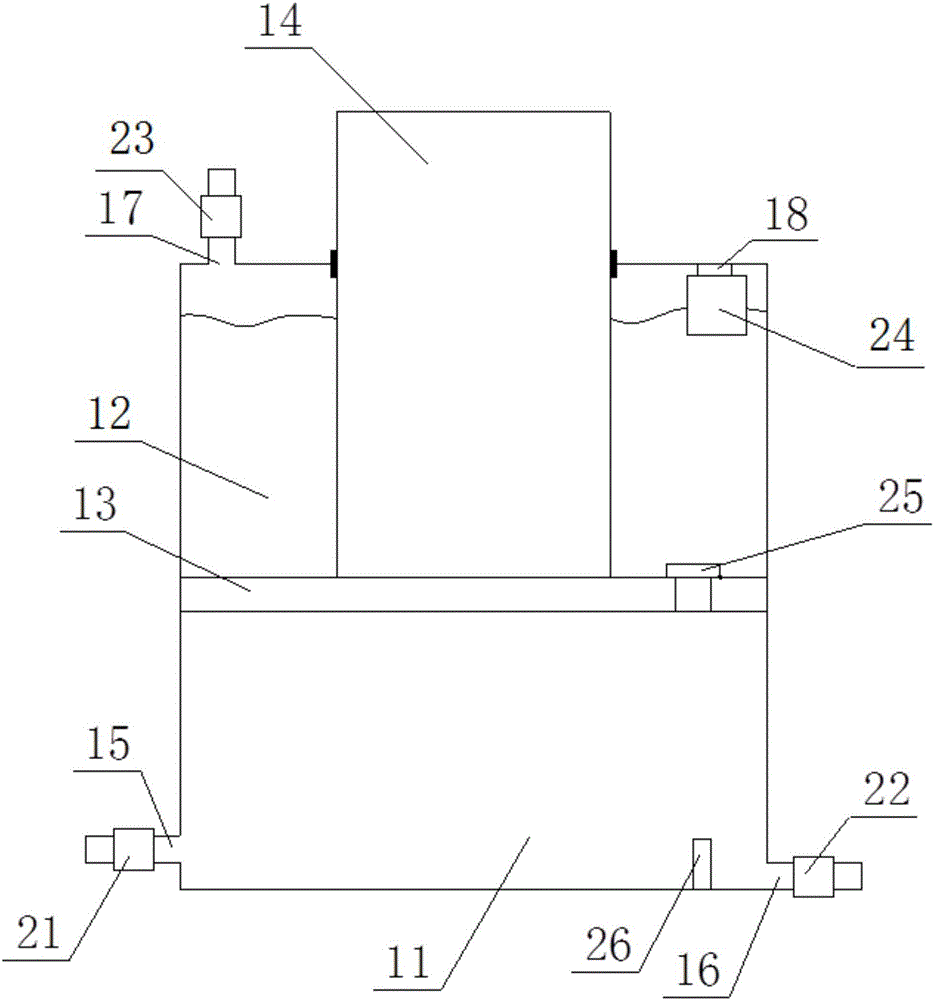

[0034] figure 1 It is a schematic structural view of the cold water recovery and reuse device of Embodiment 1 of the present invention; in the figure, the meanings indicated by each reference numeral are as follows; 11, the first cavity; 12, the second cavity; 13, the sliding piston; 14, the sliding piston rod ;15, the first water inlet; 16, the first water outlet; 17, the second water inlet; 18, the exhaust port; 21, the first water inlet valve; 22, the first water outlet valve; 23, the second water inlet valve ; 24, exhaust valve; 25, connecting valve; 26, position switch.

[0035] A cold water recovery and reuse device, including a cavity, a sliding piston 13 is arranged in the cavity, the sliding piston is connected with a sliding piston rod 14, and the density of the assembly composed of the sliding piston and the sliding piston rod is much smaller than that of water, for example, the overall Density can be 0.3 times of water density, sliding piston 13 is fixedly connect...

Embodiment 2

[0058] A shower system is provided with any one of the above-mentioned cold water recovery and reuse devices.

[0059] The shower system also has the corresponding technical effect of the above-mentioned cold water recovery and reuse device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com