Wiring terminal

A technology of connecting terminals and connecting bodies, applied in the direction of connection, conductive connection, clamping/spring connection, etc., can solve the problems of troublesome users, complex structure, and difficulty in functioning, and achieve reduced production costs, easy manufacturing, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

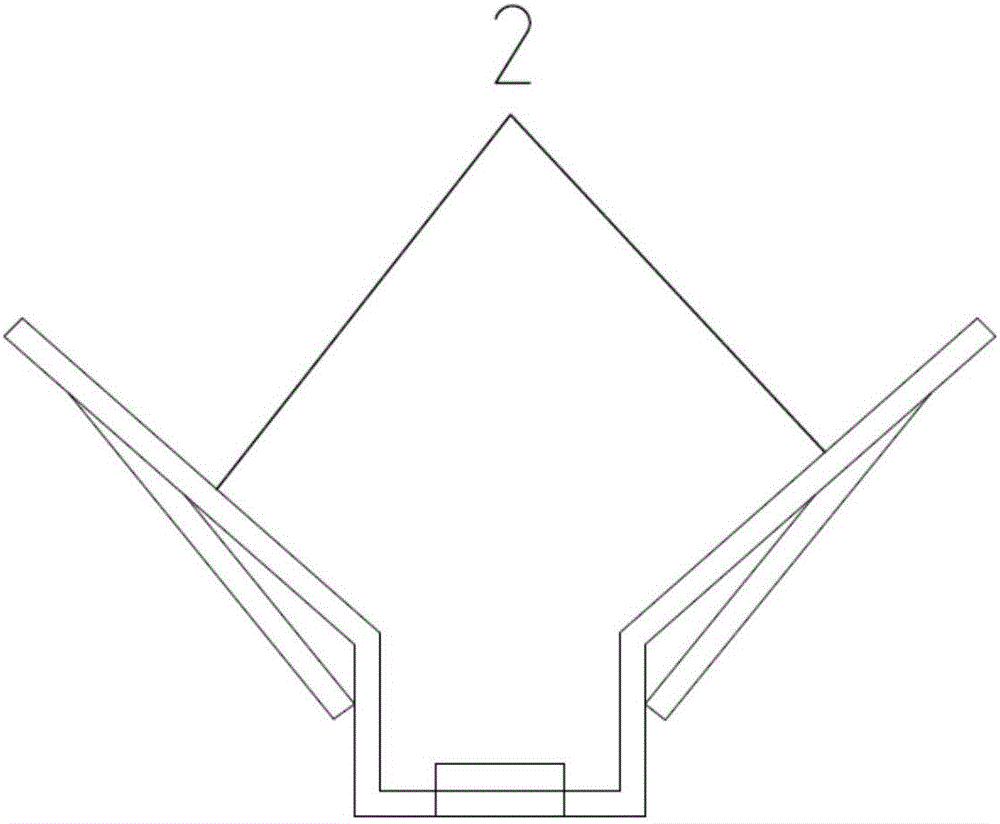

[0046] This embodiment discloses a connection terminal, such as Figure 1-8 As shown in , 13, it includes a shell 1 provided with a hollow portion 11, and two or more wiring bodies 2 that can be electrically connected to each other.

[0047] Such as Figure 6-8, 13, the casing 1 is provided with more than two first through holes 12 for the external wires 3 to pass through; a plurality of wiring bodies 2 are located in the hollow portion 11 of the casing 1; each wiring body 2 and each first through hole 12 are connected in one-to-one correspondence, so that the external wire 3 can pass through the first through hole 12 and make good contact with the wiring body 2 to realize the conductive function.

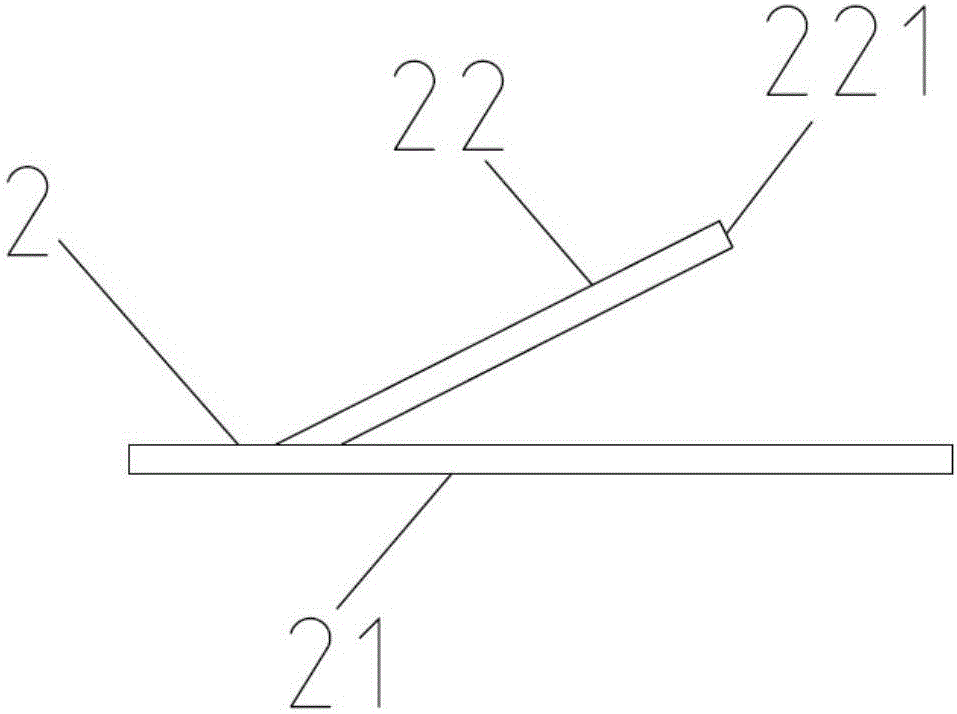

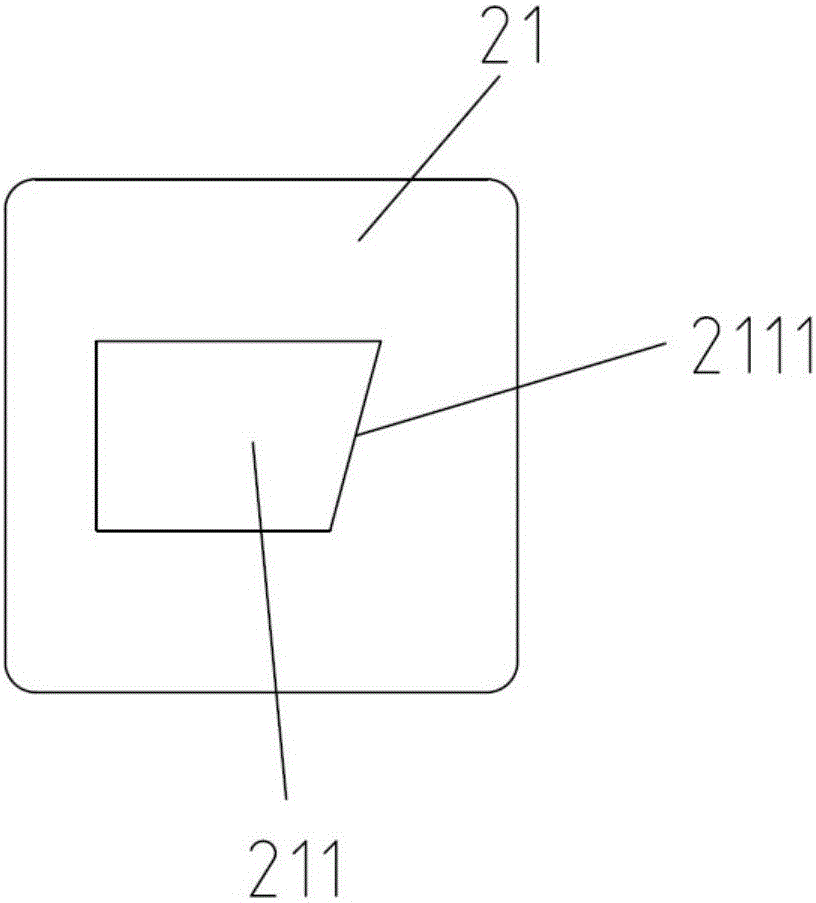

[0048] Such as figure 1 , 2 As shown, each wiring body 2 includes a supporting surface 21 and an elastic portion 22 . The supporting surface 21 is provided with a second through hole 211 with edges. In this embodiment, for the convenience of production, the elastic part 22 and ...

Embodiment 2

[0057] This embodiment discloses another connection terminal, the key differences in structure from the connection terminal described in Embodiment 1 are:

[0058] Such as Figures 9 to 12 As shown, the number of connecting pieces 4 is 2, and each connecting piece 4 includes a hooked portion 41 and a conductive connecting portion 42 connected to the hooked portion 41; the cover body 5 is provided with 6 first through holes 12, The second end 14 is provided with two first through holes 12; the six wiring bodies 2 corresponding to the six first through holes 12 on the cover body 5 are integrally formed with a fourth through hole 24 and a fifth through hole therebetween. hole 25; the conductive connection parts 42 of the two connecting pieces 4 pass through the fourth through hole 24 and the fifth through hole 25 respectively and respectively withstand the wiring body 2 corresponding to the two first through holes 12 on the second end 14, And each hook portion 42 hooks the wirin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bevel angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com