Bone-cartilage defect integrated repair bioceramic scaffold and preparation method and use thereof

A bioceramic and cartilage technology, applied in ceramic molding machines, prostheses, manufacturing tools, etc., can solve the problems that articular cartilage defects cannot be repaired, tricalcium phosphate does not have the function of cartilage repair, etc., and achieve excellent biological activity and excellent mechanical properties. Intensity, effect of increasing alkaline phosphatase activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

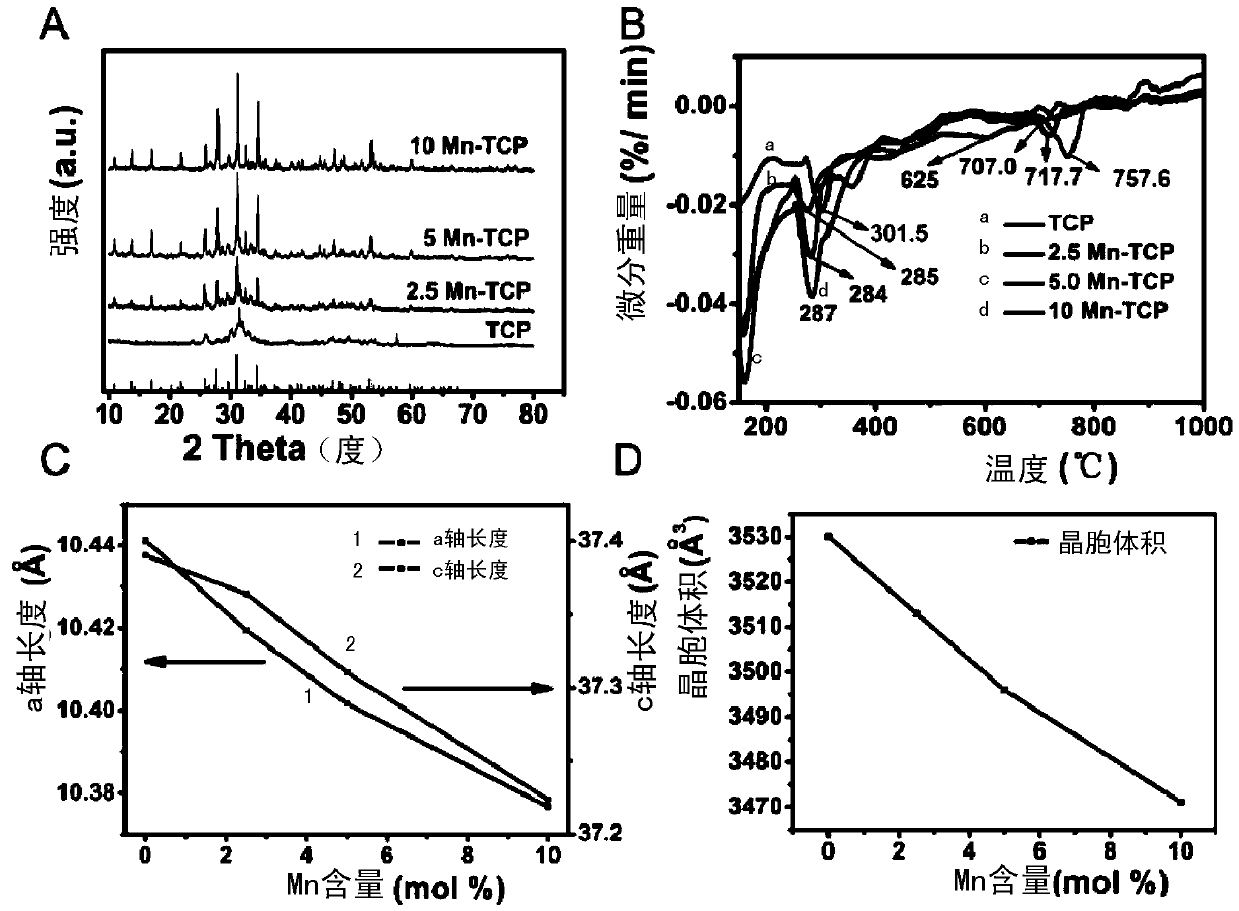

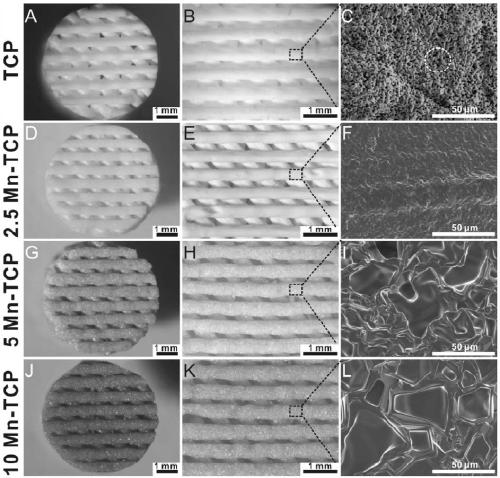

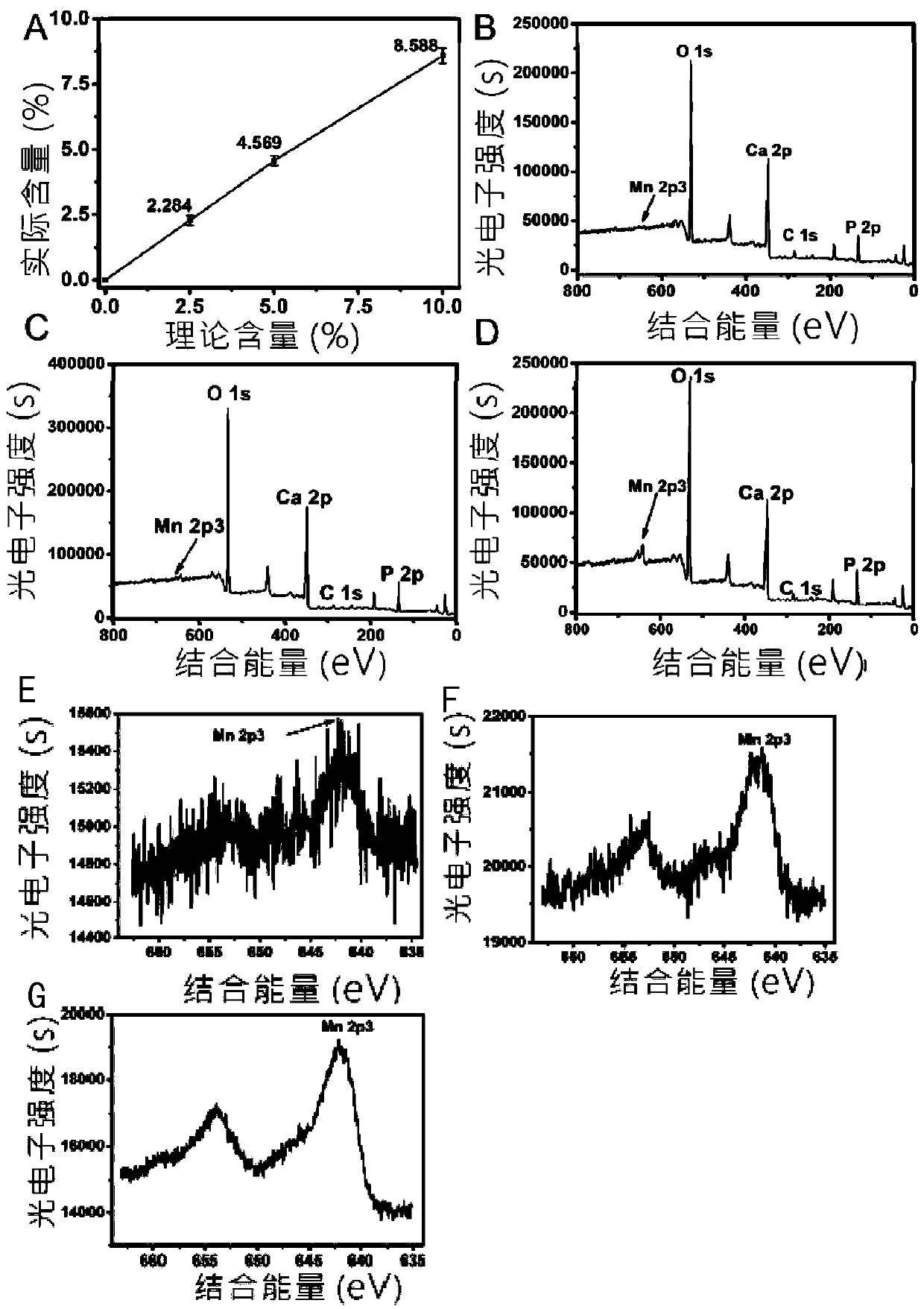

[0077] Dissolve diammonium hydrogen phosphate in deionized water (pH is 8, concentration is 0.5mol / L), manganese chloride tetrahydrate and calcium nitrate are respectively mixed and dissolved in deionized water according to the molar mass of (2.5, 5, 10): 100 In deionized water, and the resulting mixed solution of manganese chloride tetrahydrate and calcium nitrate (pH is 4.5, Mn ion concentration is respectively 0.012mol / L, 0.024mol / L, 0.05mol / L, Ca ion concentration is 0.5mol / L ) into the diammonium hydrogen phosphate solution, adjust the pH value to 7.49-7.53 with 10% ammonia water, fully stir at room temperature for 24 hours, filter with suction, and wash three times with deionized water and three times with absolute ethanol, 100 ℃ drying for 12 hours, and sintering at 800 ℃ for 3 hours to prepare Mn-TCP bioceramic powders with different Mn contents;

[0078] Mix the obtained series of Mn-TCP ceramic powder (with a particle size of 50 μm): sodium alginate (with a particle ...

Embodiment 2

[0081] Dissolve diammonium hydrogen phosphate in deionized water (pH is 7.5, concentration is 0.4mol / L), manganese chloride tetrahydrate and calcium nitrate are mixed according to the molar mass of 4:100, dissolved in deionized water, and the obtained Manganese chloride tetrahydrate and calcium nitrate mixed solution (pH is 4, Mn ion concentration is 0.02mol / L, Ca ion concentration is 0.4mol / L) is added dropwise in diammonium hydrogen phosphate solution, adjust pH with 10% ammonia water The value is 7.53-7.62, fully stirred at room temperature for 24 hours, suction filtered, washed three times with deionized water, washed three times with absolute ethanol, dried at 100°C for 12 hours, and sintered at 700°C for 4 hours to obtain Mn- TCP bioceramic powder;

[0082] The obtained Mn-TCP ceramic powder (with a particle size of 75 μm): sodium alginate (with a particle size of 20 μm): F127 (with a concentration of 10%) was mixed with a mass ratio of 1:0.05:0.6, and a printing program...

Embodiment 3

[0085] Dissolve diammonium hydrogen phosphate in deionized water (pH is 8.5, concentration is 0.6mol / L), manganese chloride tetrahydrate and calcium nitrate are mixed according to the molar mass of 7.5:100, dissolved in deionized water, and the obtained Manganese chloride tetrahydrate and calcium nitrate mixed solution (pH is 5, Mn ion concentration is 0.0375mol / L, Ca ion concentration is 0.6mol / L) is added dropwise in diammonium hydrogen phosphate solution, adjust pH with 10% ammonia water The value is 7.6-7.7, fully stirred at room temperature for 24 hours, suction filtered, washed three times with deionized water, washed three times with absolute ethanol, dried at 100°C for 12 hours, and sintered at 900°C for 5 hours to obtain Mn- TCP bioceramic powder;

[0086] The obtained Mn-TCP ceramic powder (with a particle size of 75 μm): sodium alginate (with a particle size of 50 μm): F127 (with a concentration of 15%) was mixed with a mass ratio of 1:0.15:1.0, and a printing progr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com