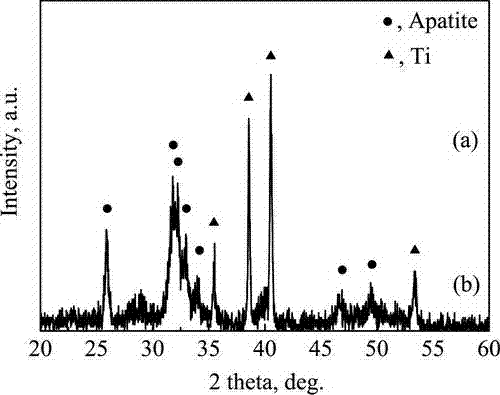

Preparation method of carbonate hydroxyapatite/carbon nano tube composite coating material

A carbon nanotube composite, hydroxyapatite technology, applied in coatings, electrolytic coatings, medical science and other directions, can solve the problems of weak adhesion between the coating and the substrate, slow deposition speed, etc., and achieves low equipment investment and good mechanics. performance, the effect of excellent in vitro biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

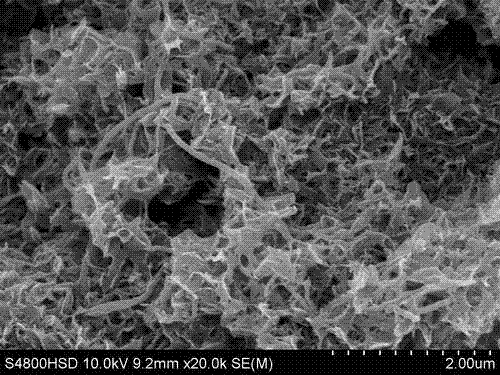

Embodiment 1

[0020] 1. Metal substrate pretreatment: use medical pure titanium as the substrate, cut it into a block with a cross-section of 15mm×15mm, polish it with metallographic sandpaper until no obvious scratches are observed under an optical microscope, and clean it with acetone and distilled water; then At 1.0 mol / L H 3 PO 4 -1.5 wt% HF mixed solution soaked for 20 min; finally washed with distilled water, dried in an oven at 60 ° C for 24 h.

[0021] 2. Preparation of the suspension: add 1.225 g of amorphous calcium carbonate powder (4-5 μm in particle size) and 0.025 g of carbon nanotubes to 250 ml of absolute ethanol, oscillate ultrasonically for 1.0 h to form a stable suspension, drop before electrophoresis Add 0.5 ml of 1.0 mol / L hydrochloric acid.

[0022] 3. Electrophoretic deposition: take the medical pure titanium obtained in step 1 as the cathode and graphite as the anode, place them in the above suspension, control the electric field strength at 90 V / cm, and deposit ca...

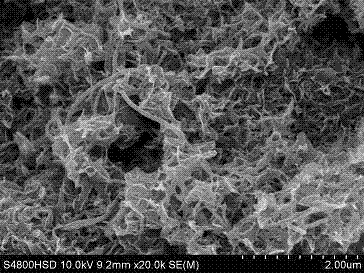

Embodiment 2

[0029] 1. Pretreatment of the metal substrate: take the medical titanium alloy Ti6Al4V as the substrate, cut it into a block with a cross-section of 15mm×15mm, polish it with metallographic sandpaper until no obvious scratches are observed under an optical microscope, and clean it with acetone and distilled water; Then in 2.0 mol / L H 3 PO 4 -0.5 wt% HF mixed solution soaked for 5 min; finally washed with distilled water, dried in an oven at 60 ° C for 24 h.

[0030] 2. Preparation of suspension: add 2.25 g of shell powder (0.1-2 μm in particle size, 98% calcium carbonate content) and 0.25 g of carbon nanotubes into 250 ml of absolute ethanol solution, disperse for 2.0 h with ultrasonic vibration, and form a stable Suspension, add 0.5 ml of 1.0 mol / L hydrochloric acid dropwise before electrophoresis.

[0031] 3. Electrophoretic deposition: take the medical titanium alloy Ti6Al4V obtained in step 1 as the cathode and graphite as the anode, place them in the above suspension, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com