Robot spraying control system

A robot control cabinet and control system technology, which is applied in the directions of manipulators, spray devices, manufacturing tools, etc., can solve the problems that the spraying robot is not easy to pull and rotate, difficult to control precise spraying, and complicated program operation, so as to achieve simple and beautiful design, improve efficiency, The effect of easy operation of the program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

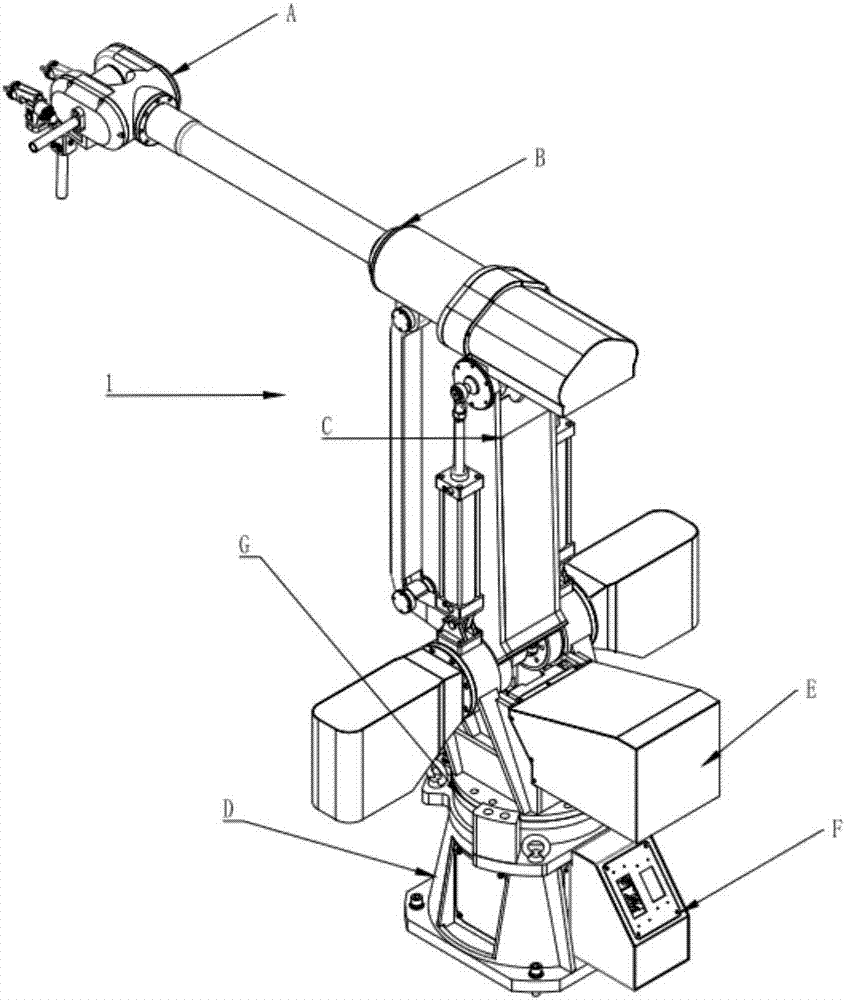

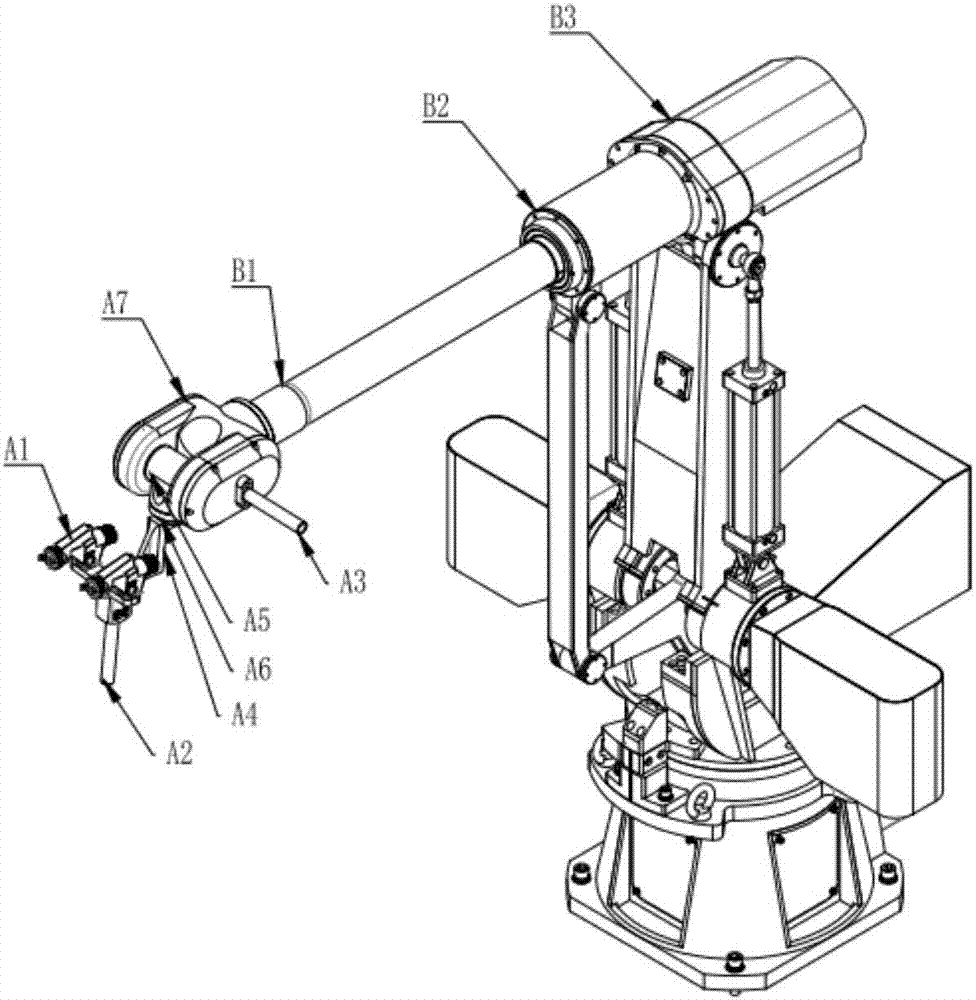

[0055] The present invention is mainly composed of a robot body and a corresponding control system. The robot adopts a articulated structure with 5 or 6 degrees of freedom. degree for flexible movement. The spraying robot is equipped with two handles, which are convenient for manual grabbing and dragging. It is also equipped with an auxiliary cylinder, so that the dragger can easily pull the robot to rotate.

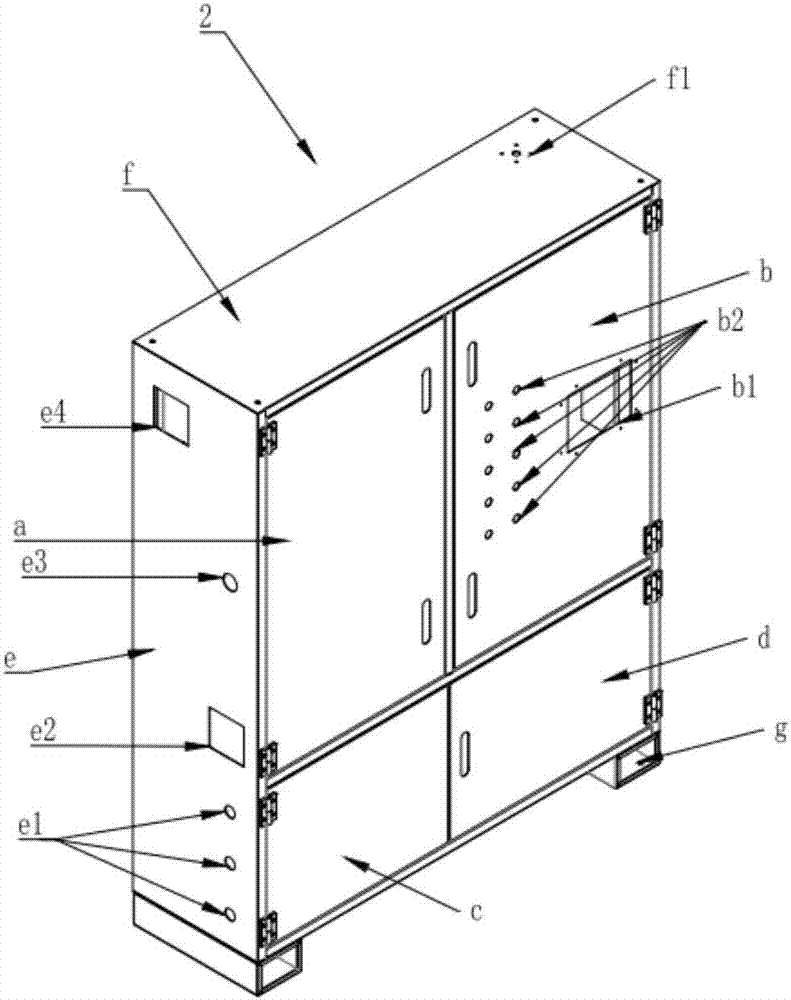

[0056] The corresponding control system is written in the controller, which can be operated through the button switch and the touch screen. When the operator presses the teaching mode (standby mode / movement mode / teaching mode / alarm) to drag the robot to move, the system will record Download the motion track of the robot and enter it into the system to save it as a motion program, and then ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com