Guardrail washing device for municipal engineering

A cleaning device and engineering technology, which can be applied to cleaning methods using liquids, cleaning methods using tools, cleaning methods and utensils, etc., and can solve the problems of high labor intensity, easy to stick a lot of dust, and slow cleaning speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

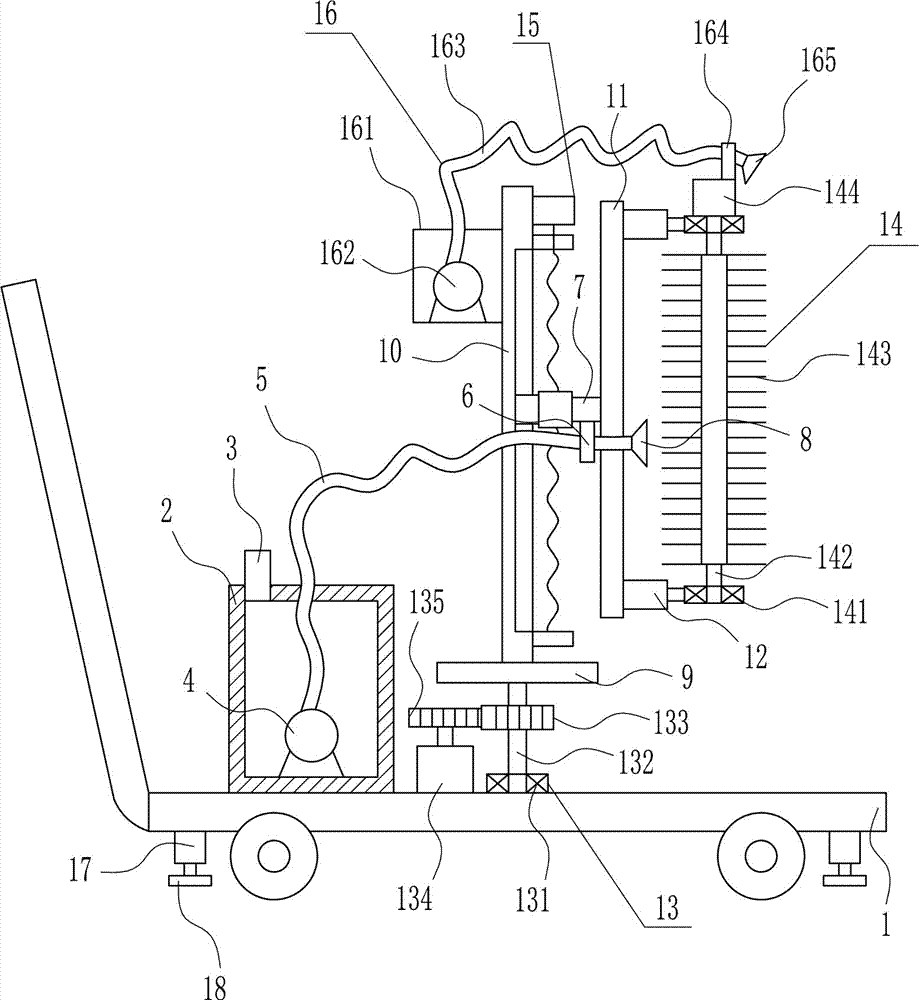

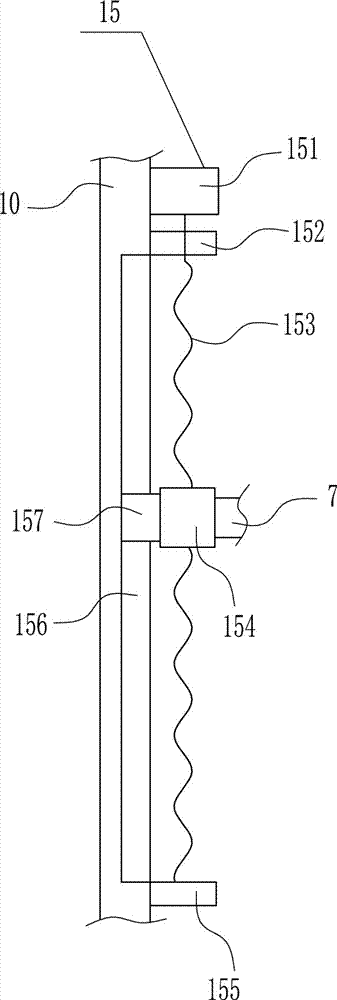

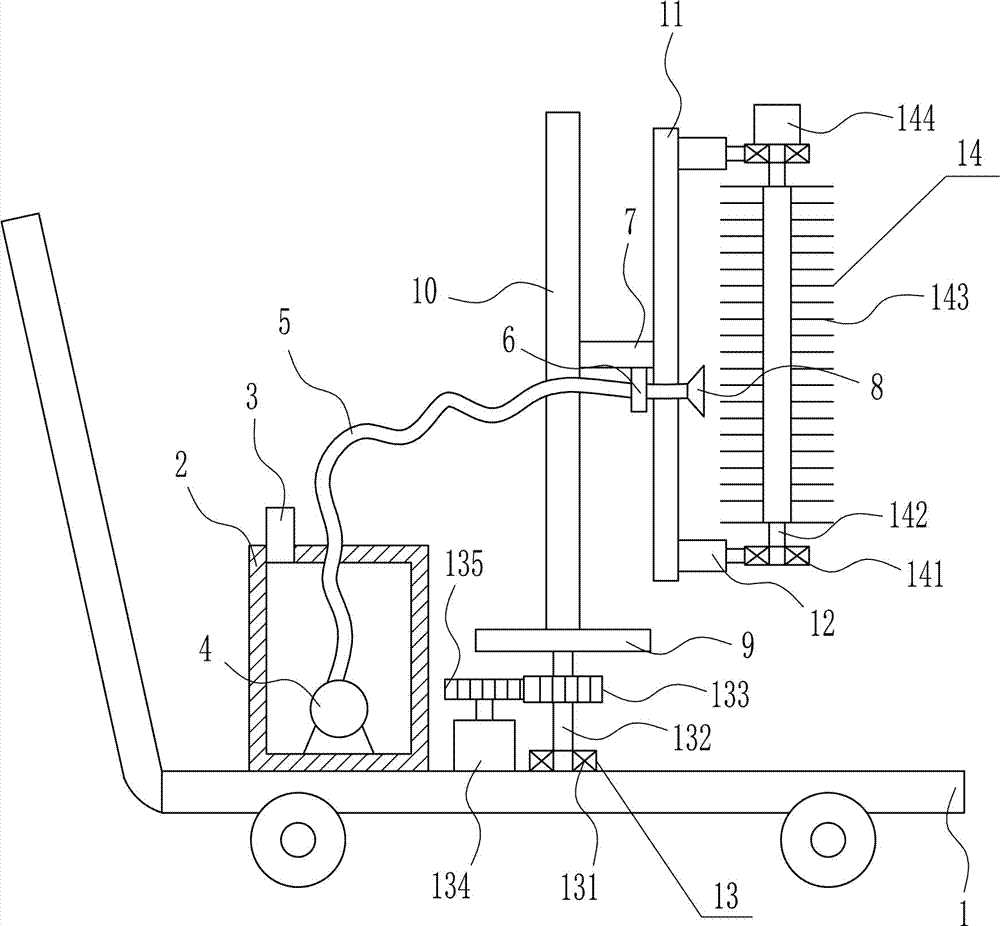

[0036] A guardrail cleaning device for municipal engineering, such as Figure 1-6 As shown, it includes a cart 1, a water tank 2, a water supply pipe 3, a water pump 4, a water outlet pipe 5, a first fixed sleeve 6, a connecting rod 7, a first nozzle 8, a fixed plate 9, a vertical plate 10, a mounting plate 11, The cylinder 12 and the rotating device 13 are provided with a rotating device 13 in the middle of the top of the cart 1. The rotating parts of the rotating device 13 are connected with a fixed plate 9, and the middle of the top of the fixed plate 9 is connected with a vertical plate 10 by bolts. The vertical plate 10 The connecting rod 7 is installed in the middle part of the right side by bolt connection, the first fixing sleeve 6 is installed on the right side of the bottom of the connecting rod 7 by bolt connection, and the mounting plate 11 is installed on the right end of the connection rod 7 by bolt connection. On the right side of the plate 11, cylinders 12 are ...

Embodiment 2

[0038] A guardrail cleaning device for municipal engineering, such as Figure 1-6 As shown, it includes a cart 1, a water tank 2, a water supply pipe 3, a water pump 4, a water outlet pipe 5, a first fixed sleeve 6, a connecting rod 7, a first nozzle 8, a fixed plate 9, a vertical plate 10, a mounting plate 11, The cylinder 12 and the rotating device 13 are provided with a rotating device 13 in the middle of the top of the cart 1. The rotating parts of the rotating device 13 are connected with a fixed plate 9, and the middle of the top of the fixed plate 9 is connected with a vertical plate 10 by bolts. The vertical plate 10 The connecting rod 7 is installed in the middle part of the right side by bolt connection, the first fixing sleeve 6 is installed on the right side of the bottom of the connecting rod 7 by bolt connection, and the mounting plate 11 is installed on the right end of the connection rod 7 by bolt connection. On the right side of the plate 11, cylinders 12 are ...

Embodiment 3

[0041] A guardrail cleaning device for municipal engineering, such as Figure 1-6 As shown, it includes a cart 1, a water tank 2, a water supply pipe 3, a water pump 4, a water outlet pipe 5, a first fixed sleeve 6, a connecting rod 7, a first nozzle 8, a fixed plate 9, a vertical plate 10, a mounting plate 11, The cylinder 12 and the rotating device 13 are provided with a rotating device 13 in the middle of the top of the cart 1. The rotating parts of the rotating device 13 are connected with a fixed plate 9, and the middle of the top of the fixed plate 9 is connected with a vertical plate 10 by bolts. The vertical plate 10 The connecting rod 7 is installed in the middle part of the right side by bolt connection, the first fixing sleeve 6 is installed on the right side of the bottom of the connecting rod 7 by bolt connection, and the mounting plate 11 is installed on the right end of the connection rod 7 by bolt connection. On the right side of the plate 11, cylinders 12 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com