Flexible rapid adjustment type vacuum suction cup suitable for energetic material machining

A vacuum suction cup and material processing technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of single structure, difficult to meet the needs of high-efficiency production of multiple varieties and small batches, lack of flexibility, etc., to achieve enhanced Reliability, improve structure, realize the effect of functional integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further elaborated below in conjunction with the accompanying drawings.

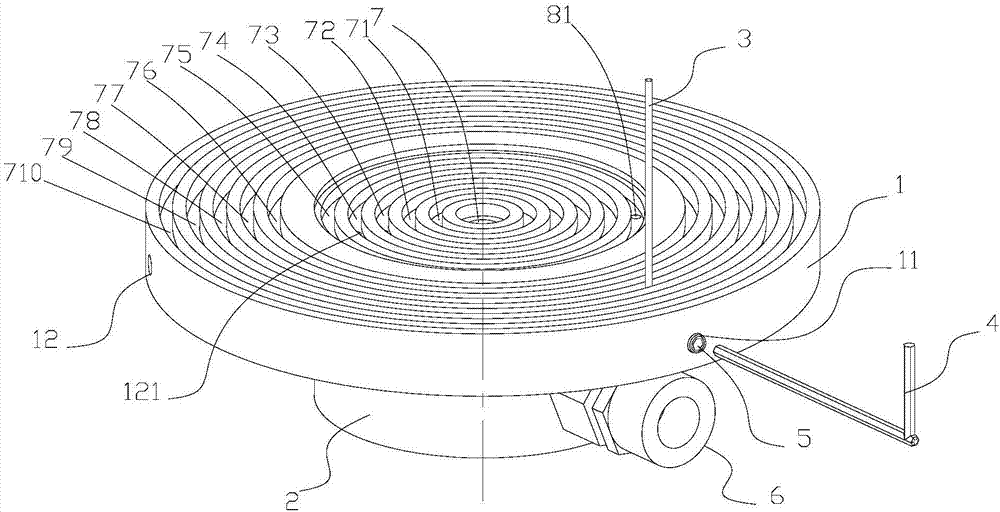

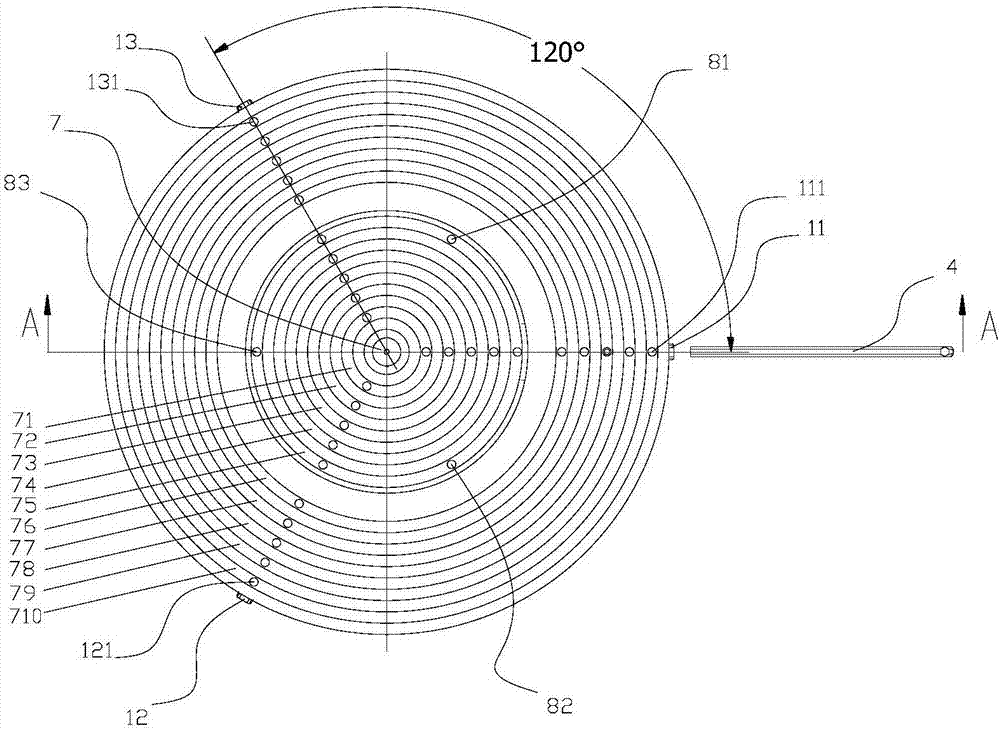

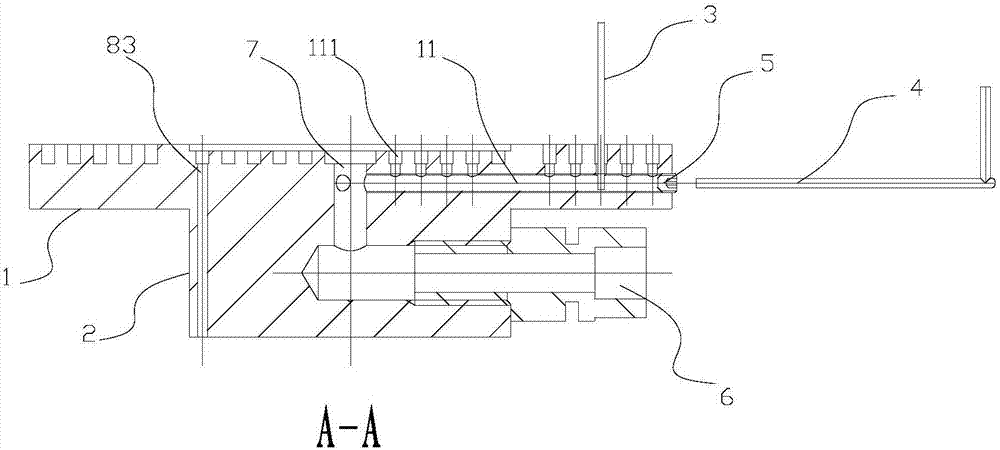

[0028] Such as Figure 1-3A flexible quick-adjust vacuum chuck suitable for the processing of energetic materials is shown, which includes a fixedly connected adsorption part 1 and a positioning part 2, and a central air guide hole 7 is opened at the center of the surface of the adsorption part 1, and the adsorption part 1 The surface is provided with ten circular grooves, and the ten circular grooves are respectively a first circular groove 71, a second circular groove 72, a third circular groove 73, a fourth circular groove 74, The fifth circular groove 75, the sixth circular groove 76, the seventh circular groove 77, the eighth circular groove 78, the ninth circular groove 79 and the tenth circular groove 710, and the One circular groove 71, the second circular groove 72, the third circular groove 73, the fourth circular groove 74, the fifth circular groove 75, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com