Device capable of automatically winding nylon sheath

A nylon sheath, automatic technology, applied in the field of winding devices, can solve the problems of low work efficiency, can not meet automatic production, high labor intensity, etc., and achieve the effects of low labor intensity, reasonable structure design, and high winding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

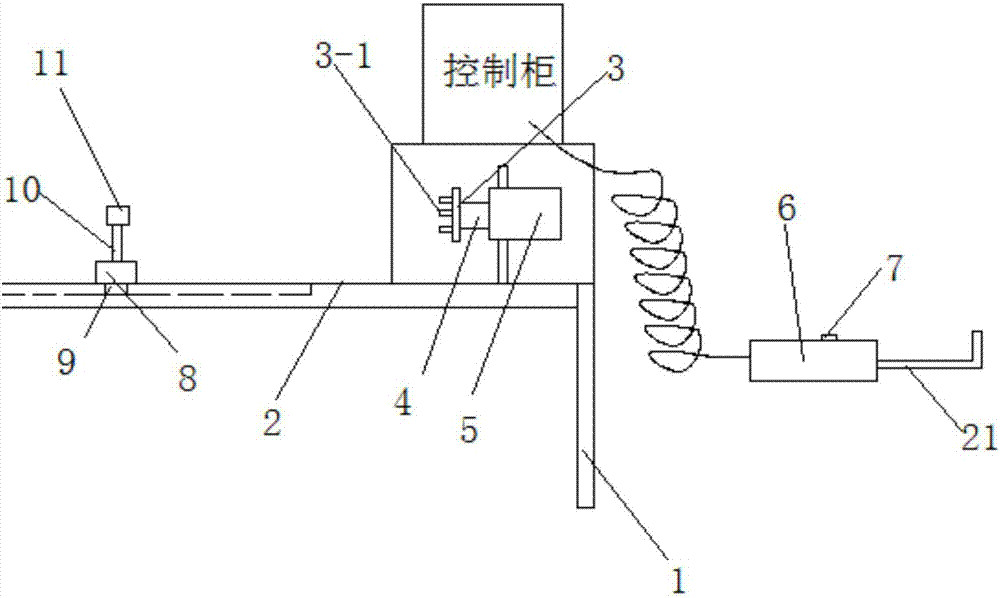

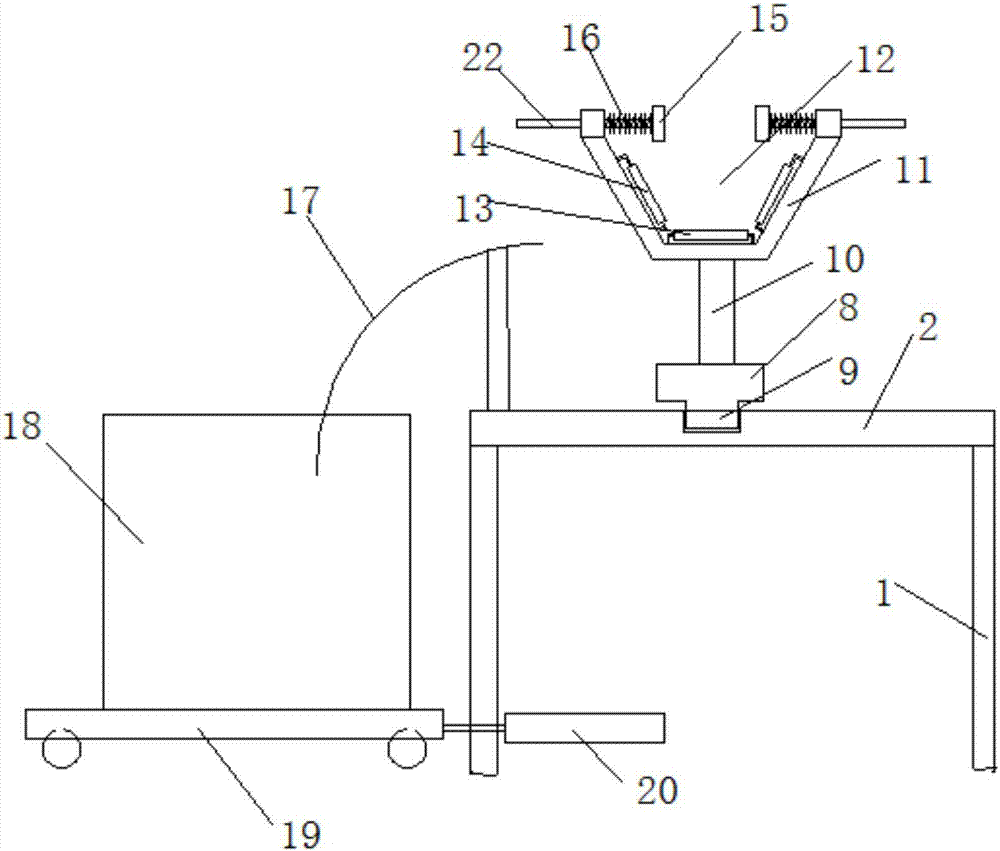

[0015] See attached picture.

[0016] An automatic winding nylon sheath device includes a frame 1, on which a workbench 2 is mounted. One end of the workbench 2 is equipped with a three-jaw chuck 3 for clamping. The three-jaw chuck The three-jaw 3-1 of 3 is driven by the three-jaw cylinder 5 behind it. The rotation of the three-jaw chuck 3 is driven by the motor 5 at the rear end of the three-jaw cylinder 4, and the motor 5 is controlled by pressing the contact switch on the handle 6. A hook 21 is installed at the front end of the handle, and a support mechanism for clamping the elastic hose is installed on the workbench.

[0017] The handle is provided with a card slot, and an elastic button switch 7 is clamped in the card slot, and the elastic button switch 7 is connected to the motor 5 through a signal wire to control the operation of the motor.

[0018] The supporting mechanism includes a guide seat 8, and a guide rail 9 is provided at the bottom end of the guide seat 8. The gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com