Self-cleaning antibacterial glazed ceramic tile and production technology thereof

A technology of glazed tiles and porcelain, which is applied in the field of self-cleaning antibacterial porcelain glazed tiles and its manufacturing process, which can solve the problems of affecting brick shape and brick bending performance, weakening the effect of nano-antibacterial layer, and complex fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

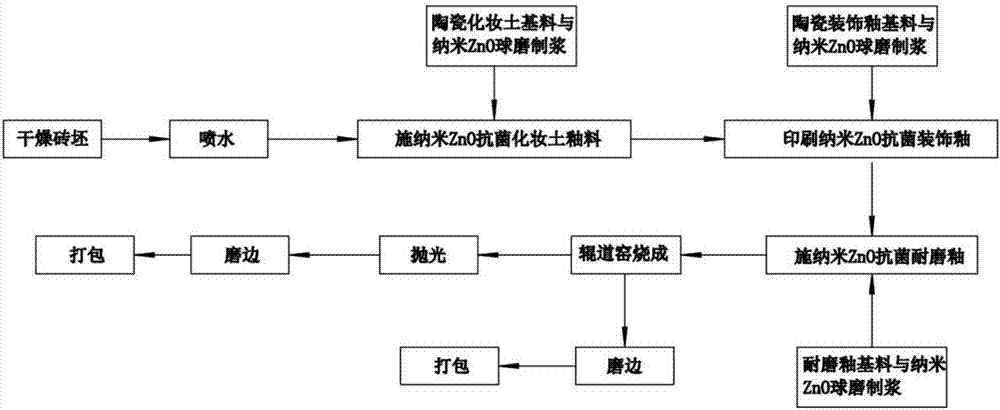

[0030] The present invention will be further described below in conjunction with accompanying drawing:

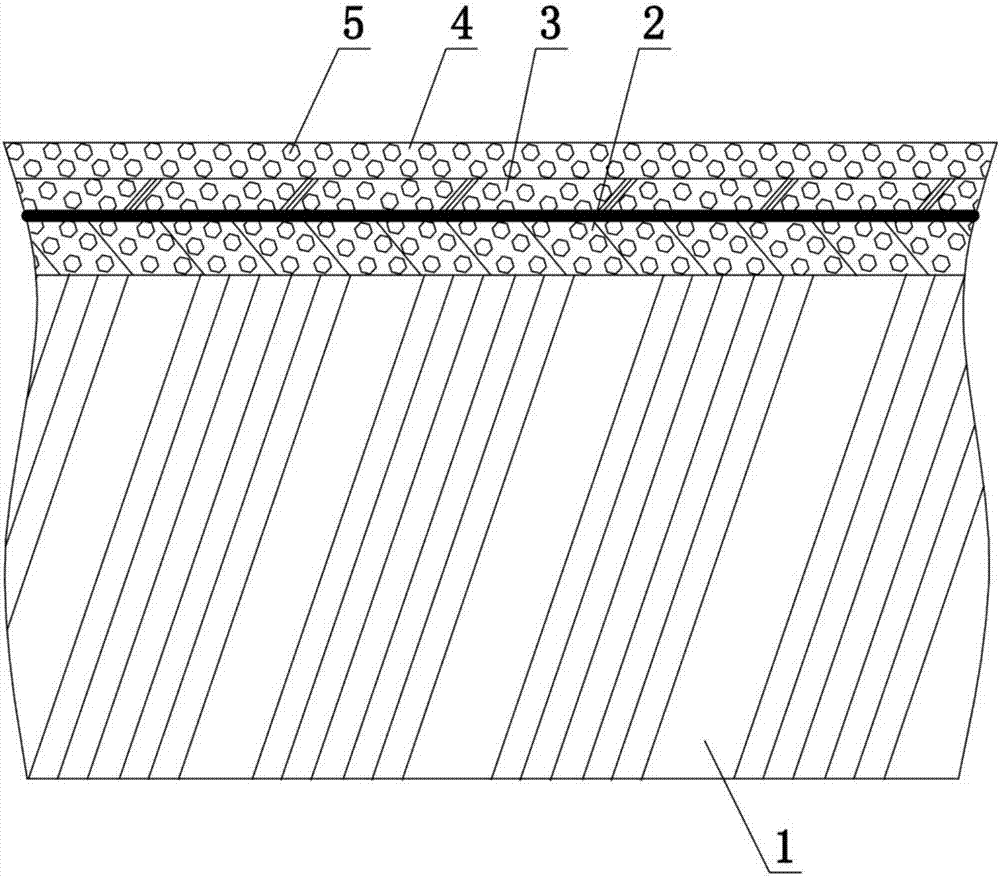

[0031] Such as Figure 1 to Figure 2 As shown, the technical scheme adopted by the present invention is as follows: a self-cleaning and antibacterial porcelain glazed tile, including a ceramic tile embryo body layer 1 and a makeup soil layer 2 and a pattern coated on the tile embryo body layer 1 sequentially from the inside to the outside. Decorative layer 3 and wear-resistant layer 4, wherein, add nano ZnO antibacterial agent respectively in the base material of above-mentioned make-up soil layer 2, pattern decorative layer 3 and wear-resistant layer 4, form three antibacterial layers on the surface of ceramic tile embryo body layer 1 .

[0032] The tile embryo body layer 1 is a dry-pressed tile embryo body, the surface of which is a flat or convex surface and an antique concave-convex surface with a pit depth not greater than 1mm.

[0033] The make-up soil layer 2 is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com