Three-element Co-Zn-Fe alloy of beta-Mn phase and preparation method thereof

A three-element, alloy technology, applied in the field of functional materials, can solve the problem that there is no work report on the three-element CoZnFe alloy, and achieve the effects of easy control of experimental conditions, simple equipment and good uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Mixing Co powder, Zn powder and Fe powder with a purity of 99.9% according to a molar ratio of 2:2:1, and fully grinding for 4 hours to obtain a uniformly distributed powder mixture for preparing CoZnFe alloy;

[0024] 2) Use mechanical pump equipment to vacuumize the quartz glass tube containing the powder mixture for 30 minutes, and then seal the quartz glass tube to keep the vacuum state in the tube;

[0025] 3) Put the sealed quartz glass tube containing the sample into a muffle furnace for sintering, rapidly raise the temperature to 1100°C at a rate of 200°C / h, and keep this temperature for 12h; then cool down to 1025°C at a rate of 1°C / h ℃; keep at 1025℃ for 75h;

[0026] 4) Finally, take out the quartz glass tube with the sample at 1025°C, put it into water and quench it, and take it out to get the prepared CoZnFe sample. The chemical composition of the prepared CoZnFe alloy is Co 8 Zn 8 Fe 4 .

Embodiment 2

[0028] 1) Mixing Co powder, Zn powder and Fe powder with a purity of 99.9% according to a molar ratio of 4.5:4.5:1, and fully grinding for 4 hours to obtain a uniformly distributed powder mixture for preparing CoZnFe alloy;

[0029] 2) Use mechanical pump equipment to vacuumize the quartz glass tube containing the powder mixture for 30 minutes, and then seal the quartz glass tube to keep the vacuum state in the tube;

[0030] 3) Put the sealed quartz glass tube containing the sample into a muffle furnace for sintering, rapidly raise the temperature to 1100°C at a rate of 200°C / h, and keep this temperature for 12h; then cool down to 1025°C; keep at 1025°C for 75h;

[0031] 4) Finally, take out the quartz glass tube with the sample at 1025°C, put it into water and quench it, and take it out to get the prepared CoZnFe sample. The chemical composition of the prepared CoZnFe alloy is Co 9 Zn 9 Fe 2 .

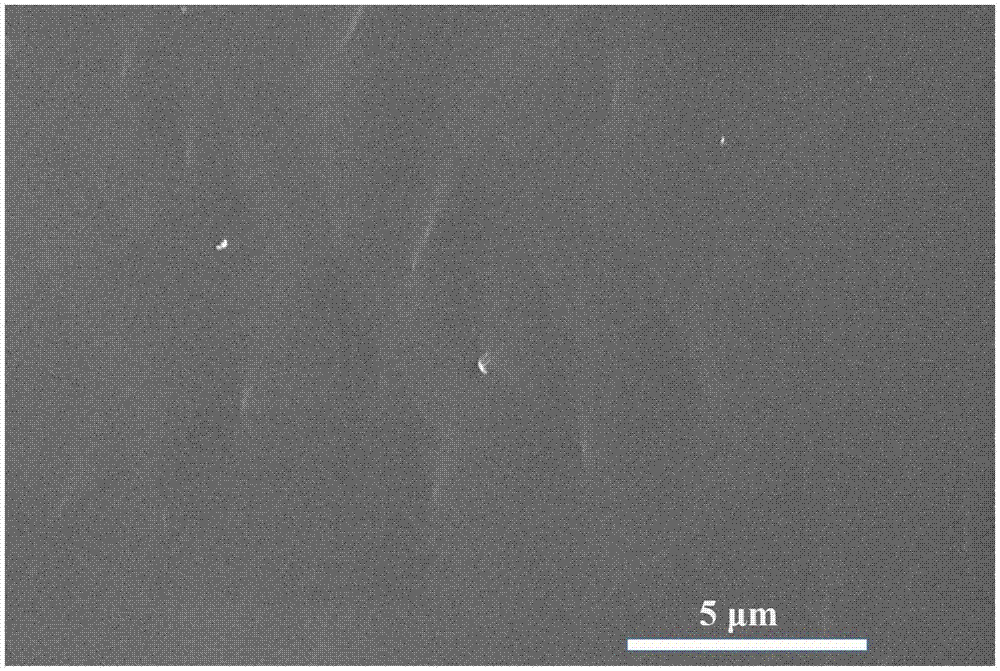

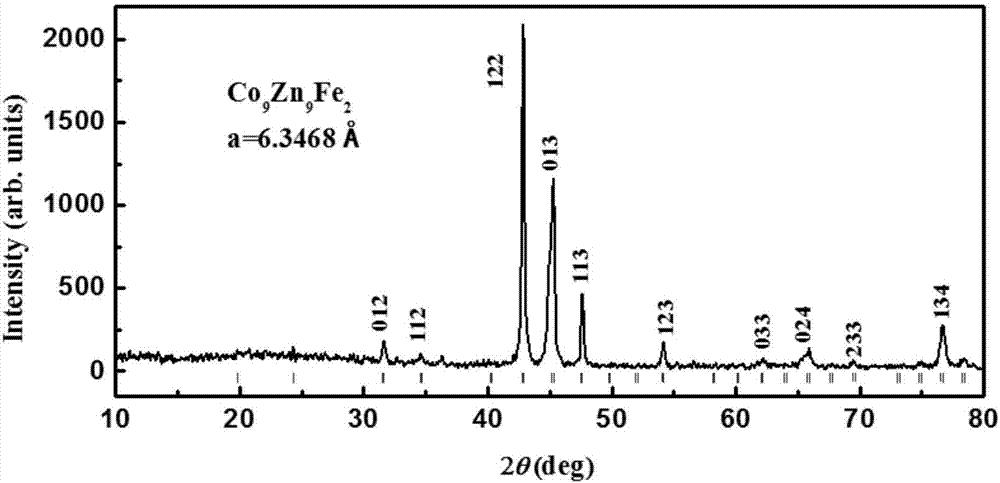

[0032] The morphology of a three-element CoZnFe alloy with a single β-Mn pha...

Embodiment 3

[0035] 1) Mixing Co powder, Zn powder and Fe powder with a purity of 99.9% according to a molar ratio of 4:5:1, and fully grinding for 4 hours to obtain a uniformly distributed powder mixture for preparing CoZnFe alloy;

[0036] 2) Use mechanical pump equipment to vacuumize the quartz glass tube containing the powder mixture for 30 minutes, and then seal the quartz glass tube to keep the vacuum state in the tube;

[0037] 3) Put the sealed quartz glass tube containing the sample into a muffle furnace for sintering, rapidly heat it to 1100°C at a rate of 200°C / h, and keep this temperature for 12h; then cool it down to 1025°C; keep at 1025°C for 75h;

[0038] 4) Finally, take out the quartz glass tube with the sample at a temperature of 1025° C., put it into water to quench, and take it out to obtain the prepared CoZnFe sample. The chemical composition of the prepared CoZnFe alloy is Co 8 Zn 10 Fe 2 .

[0039] 1. The present invention selects Co 10 Zn 10CoZnFe alloy is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com