Quasi large-diameter pile formed by bunching plurality of small-diameter piles and construction method of quasi large-diameter pile

A construction method and large-diameter technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as restrictions, limited number of pile foundation construction machines, and difficult construction, so as to increase the scope of application and reduce construction difficulty , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments, but the embodiments should not be construed as limiting the present invention.

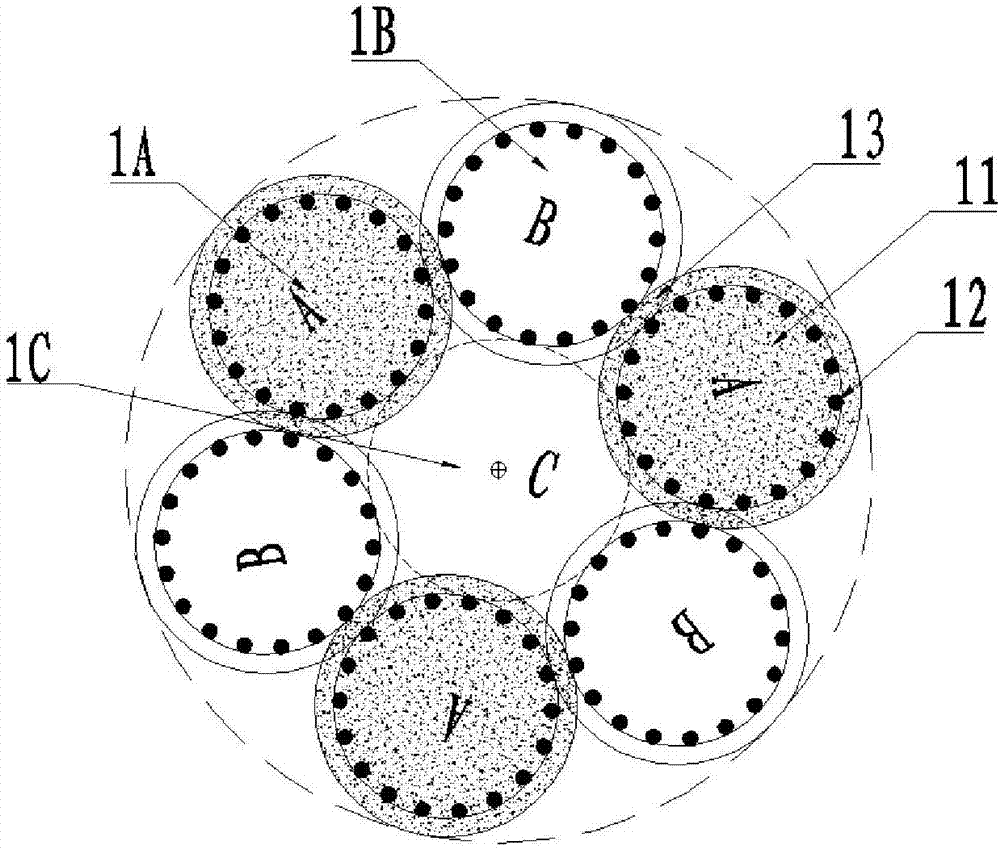

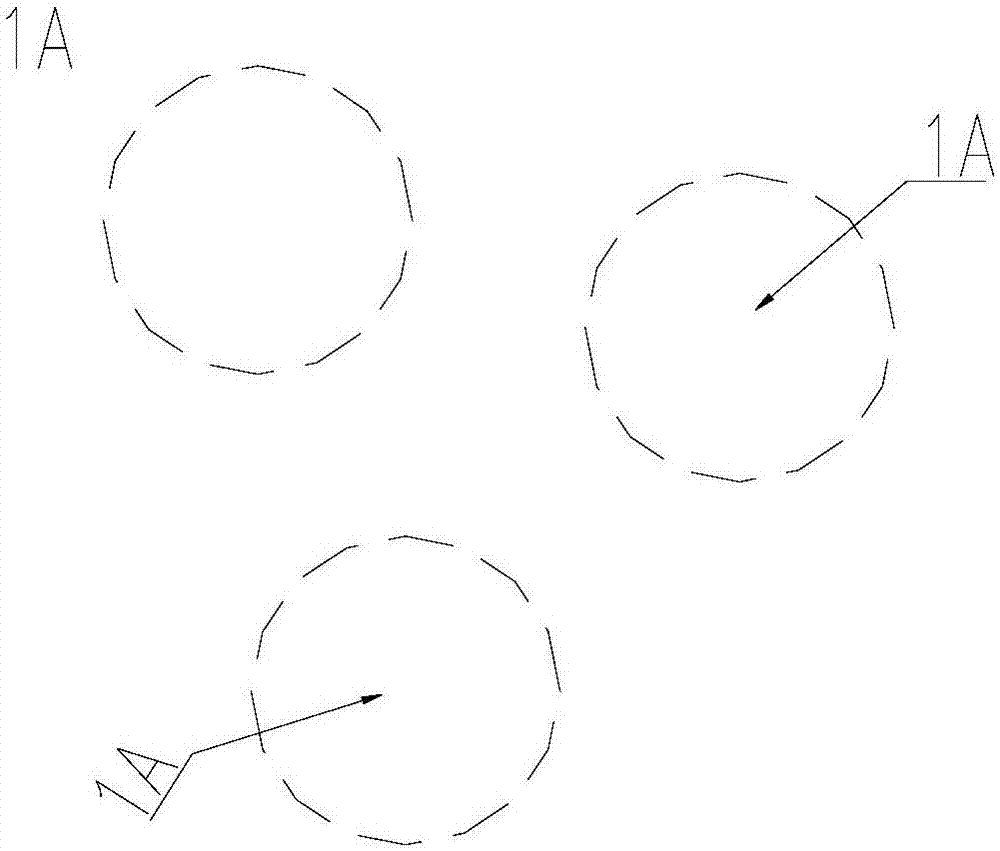

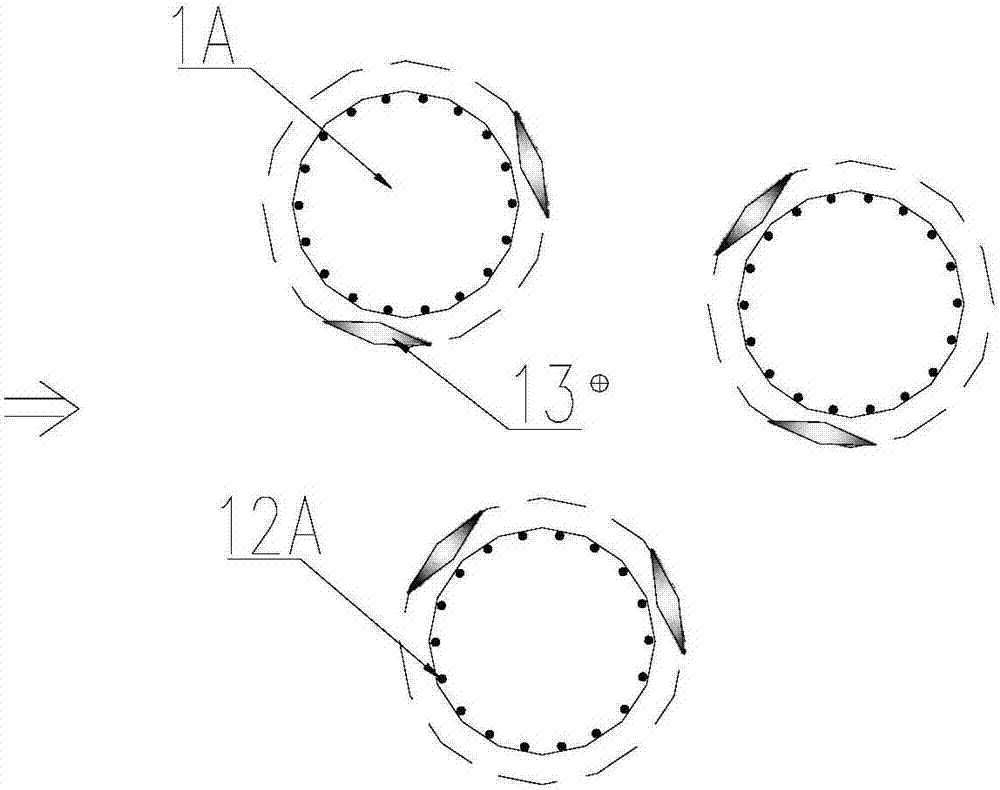

[0035] like figure 1 As shown in the figure, a kind of large-diameter pile synthesized by a plurality of small pile bundles of the present invention includes several foundation pile units 1 with the same structure. shape or sector. The foundation pile unit 1 is a reinforced concrete structure, mostly with a circular cross-section, and is composed of a concrete main body 11 and a built-in reinforcement cage 12. The reinforcement cage 12 can be a circular reinforcement cage 12a or a fan-shaped reinforcement according to the size of the occlusal groove 13 of the pile body. The cage 12b, on the basis of the reinforcement cage 12, removes the reinforcement of the pre-construction foundation pile unit 1 within the occlusal section to form an occlusion groove 13 to prevent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com