Superconducting phase change electric heater

A technology of electric heaters and superconducting phases, applied in the field of superconducting phase change electric heaters, can solve problems such as low electrothermal conversion efficiency, low comfort, and slow heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

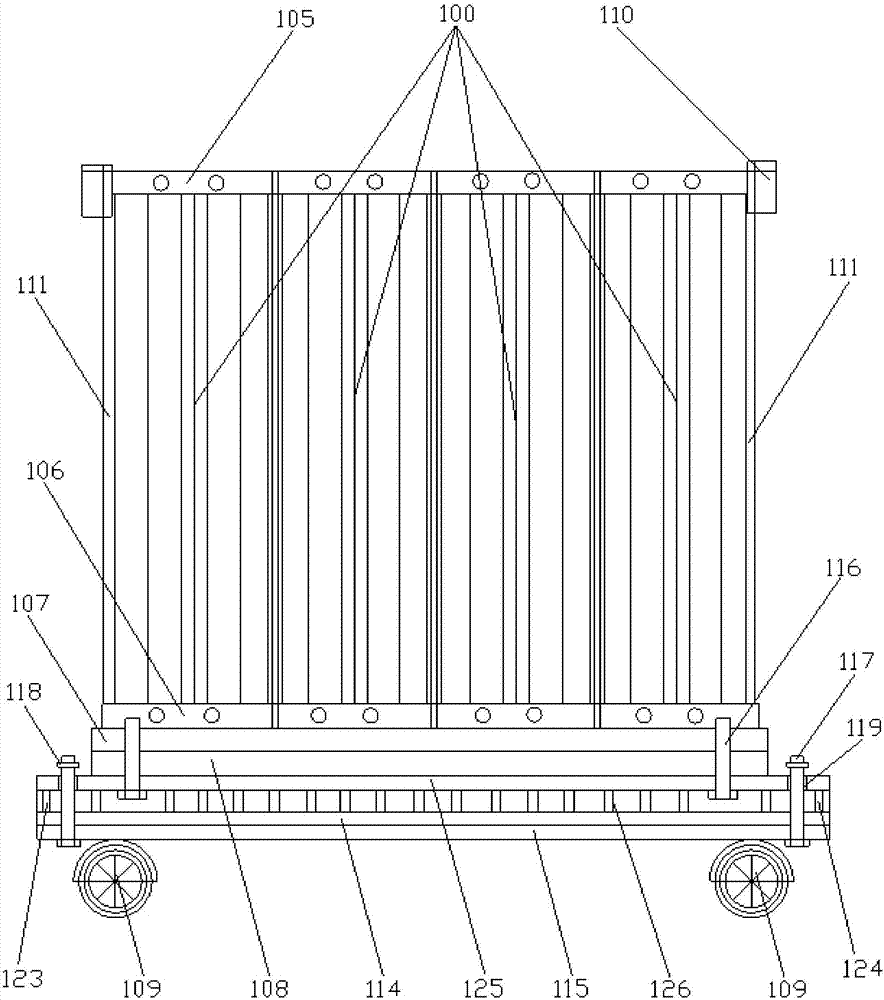

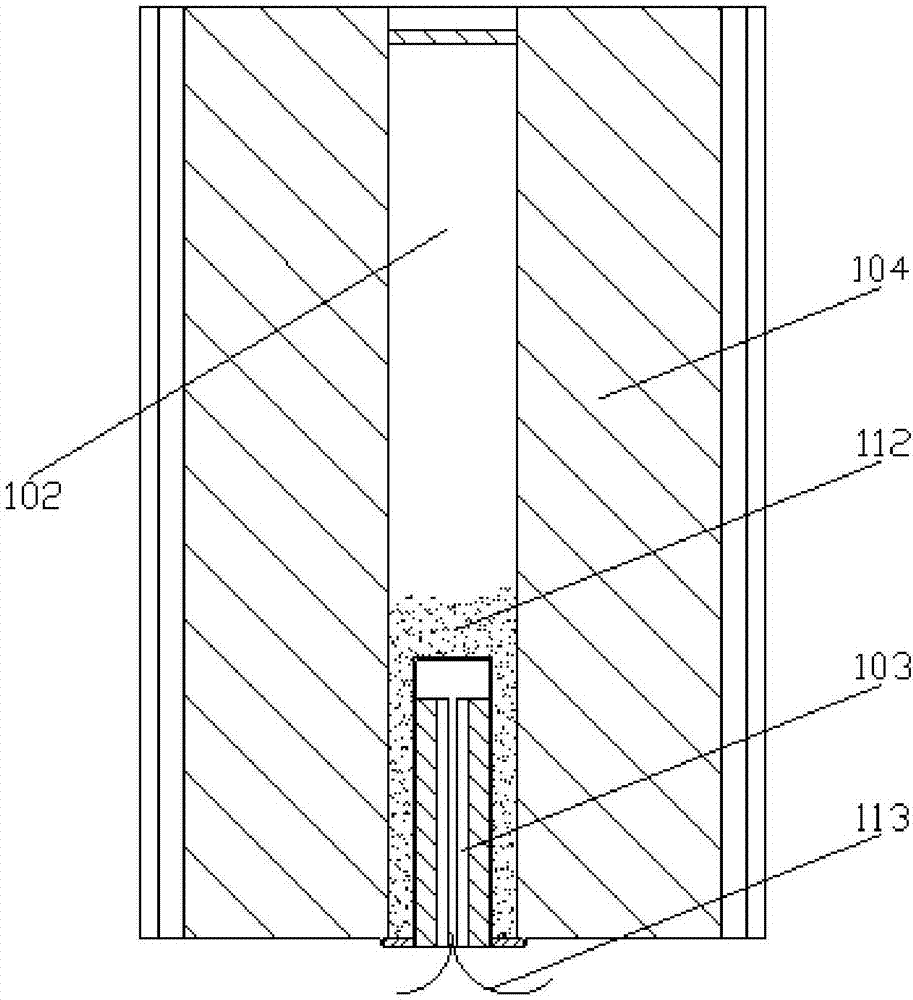

[0030] Such as Figure 1 to Figure 2 Shown: the superconducting phase-change electric heater of the embodiment of the present invention includes several phase-change superconducting heating devices 100, and only one phase-changing superconducting heating device 100 can be selected, and the phase-change superconducting heating device 100 includes A metal radiator 104, the metal radiator 104 is provided with a vacuum steel pipe 102, the vacuum steel pipe 102 is equipped with a phase change superconducting liquid, the bottom of the vacuum steel pipe 102 is provided with a groove 112, and the groove 112 is provided with There is a PTC heating rod 103, and the PTC heating rod 103 is closely attached to the wall of the groove 112, and the PTC heating rod 112 is connected with a wire 113; the top of the phase change superconducting heating device 100 is passed through the first connecting button 105, the bottom of the phase change superconducting heating device 100 is connected throu...

Embodiment 2

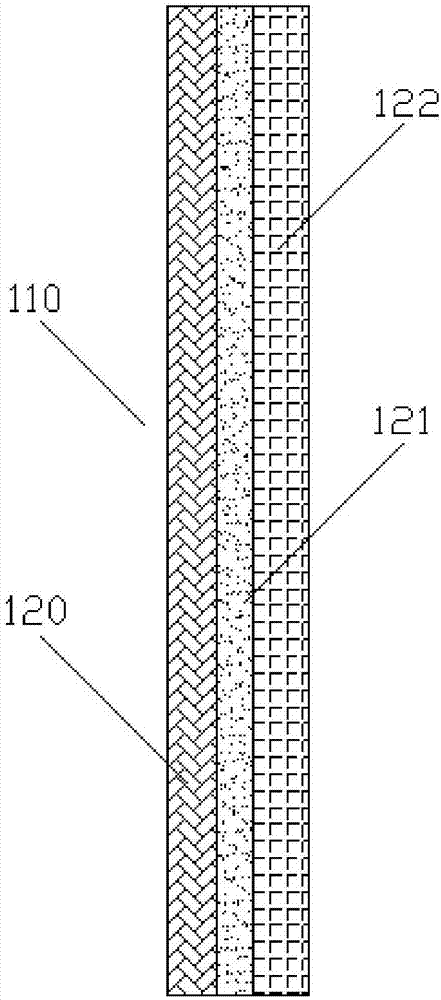

[0039] Such as image 3 As shown, in the superconducting phase change electric heater provided by the present invention, on the basis of the above structure, the outer sides of the phase change superconducting heating device 100 on both sides are provided with a flame retardant device 111, and the flame retardant The flame retardant device 111 includes a flame retardant skin 122 wherein:

[0040] The flame retardant surface layer 122 is leather made of low plasticizer polyvinyl chloride material, and a flame retardant is added inside the flame retardant surface layer 122, and an adhesive layer 121 is combined on one side of the flame retardant surface layer 122, and the low plasticizer polyvinyl chloride The flame retardant surface layer of vinyl material has the effect of anti-slip and wear resistance, and a flame retardant is added inside the flame retardant surface layer to make it have a flame retardant effect;

[0041] The adhesive layer 121 is an adhesive bonded to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com