Omnidirectional wheel chassis capable of assisting in supporting and positioning

A technology of auxiliary support and omni-directional wheels, which is applied in the direction of the launch device, can solve the problems of low friction between the omni-directional wheels and the ground, complex connectors, side shifting, etc., and achieve the effect of easy implementation, simple structure, and elimination of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution adopted by the omni-directional wheel chassis that can assist support and positioning of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

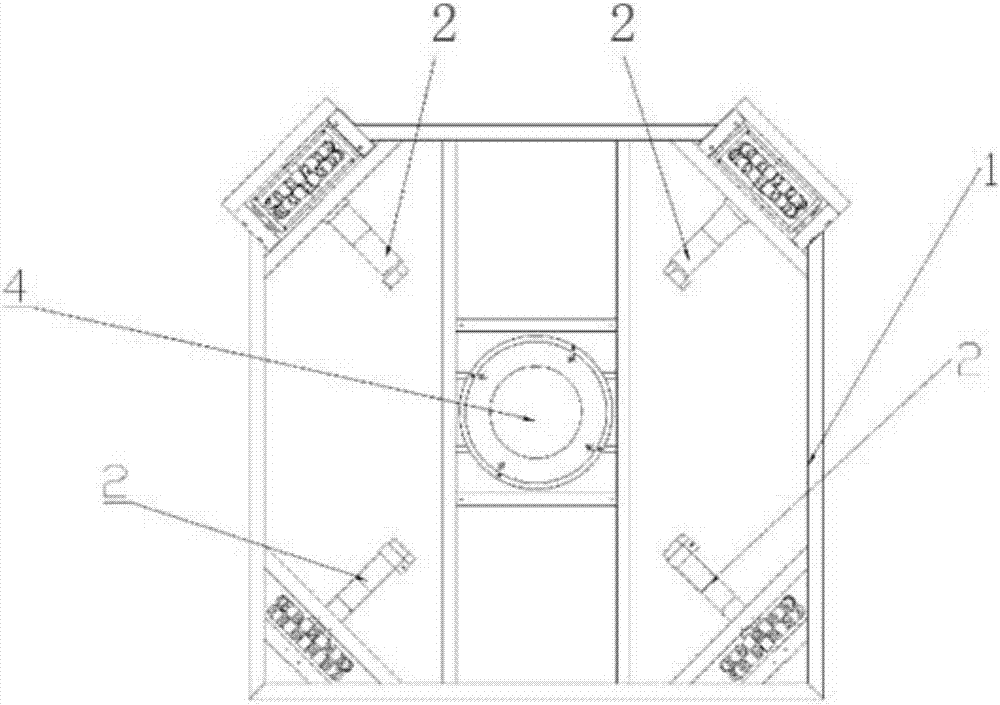

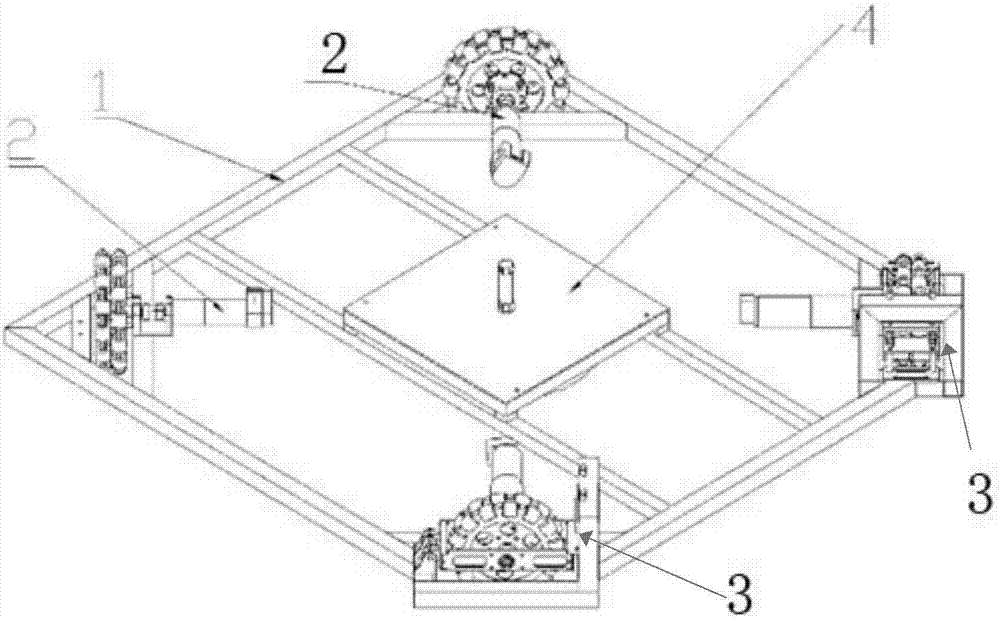

[0028] like figure 1 and figure 2 As shown, an omnidirectional wheel chassis that can assist support positioning, including:

[0029] The chassis frame 1 is a square frame structure;

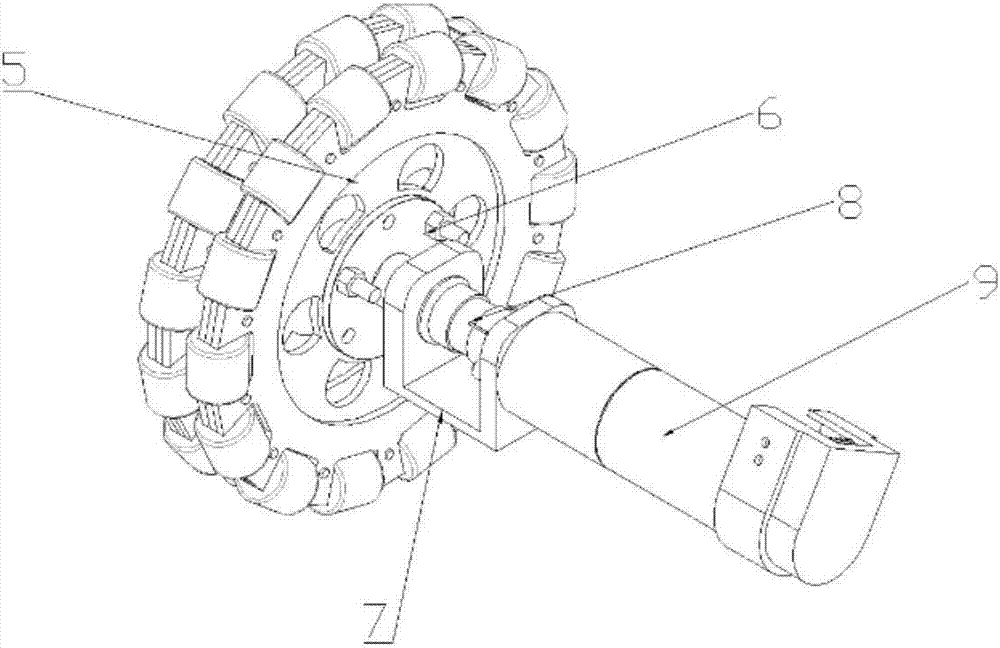

[0030] The four omnidirectional wheel drive systems 2 are respectively arranged at the corners of the chassis frame 1, and the chassis frame 1 is provided with through holes, and the four omnidirectional wheel drive systems 2 are fixed on the said chassis frame 1 by bolts in the through holes. The corresponding position of the chassis frame 1;

[0031] The launch fastening mechanism 4 is fixedly arranged at the center position of the chassis frame 1, and includes a cylinder 15, a cylinder fixing plate 14, a plane bearing 16, and a launch fixing block 17 from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com