Mistake-proof detection method for structural member assembly in manufacturing industries of automobiles, machines or home appliances

A technology for structural parts and manufacturing, applied in the field of error-proofing detection of structural parts assemblies, can solve problems such as large influence of human factors, difficulty in achieving complete differentiation, differences in parts structure, color, and material, and achieve good economic and social benefits. effectiveness, improved accuracy and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

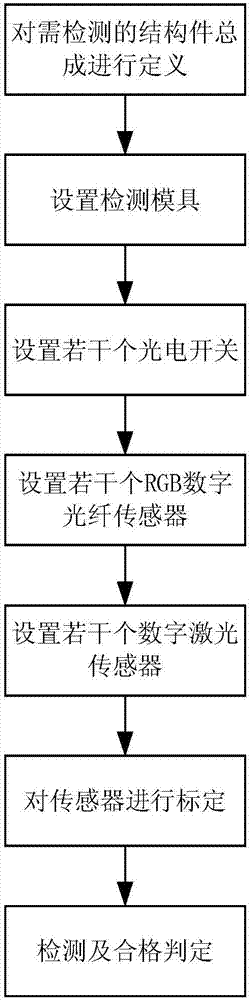

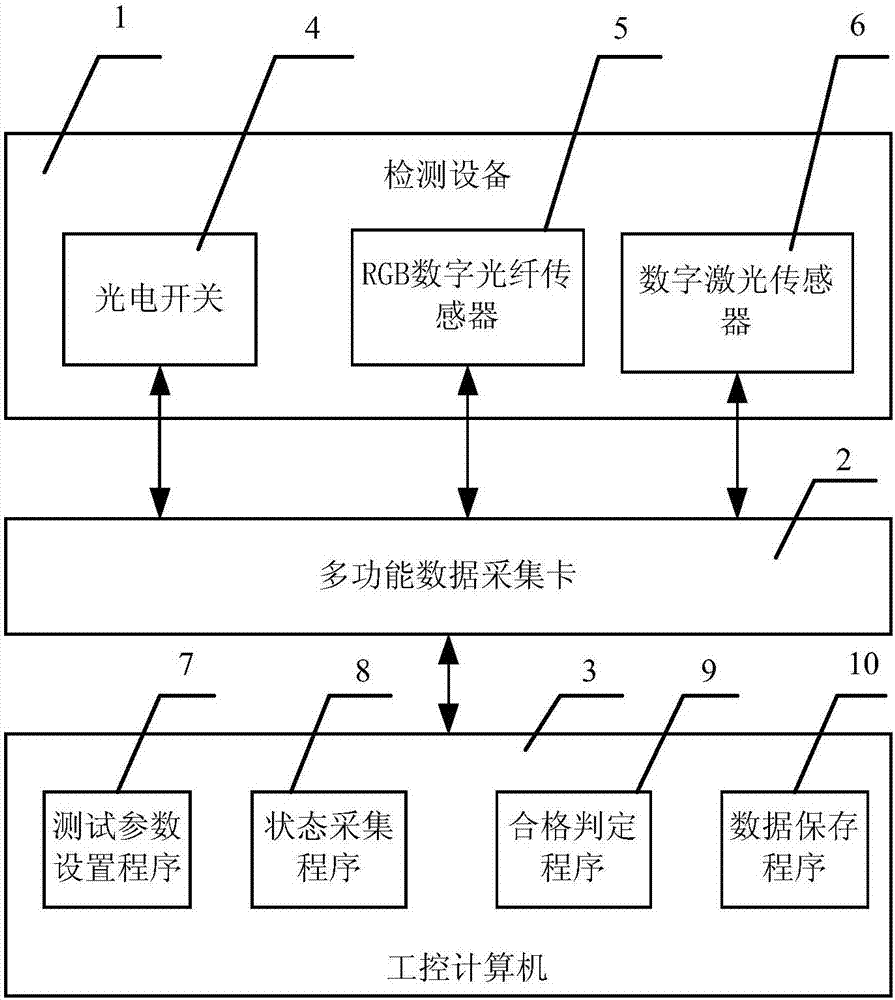

[0021] see figure 1 with figure 2 , for the error-proof detection method of structural parts assembly in the automobile, machinery or household appliance manufacturing industry, it is characterized in that: comprise the following steps:

[0022] Step 1. Define the structural assembly to be tested

[0023] Divide the structural assembly to be tested into several parts; then define the items to be tested for each part;

[0024] Step 2, setting a testing mold, which matches the size of the structural component assembly to be tested, and installing the testing mold in the testing device 1;

[0025] Step 3, setting several photoelectric switches 4 in the detection equipment, and the number of photoelectric switches 4 is consistent with the number of parts to be detected, and corresponds to the parts to be detected;

[0026] Step 4, setting several RGB digital fiber optic sensors 5 in the detection equipment, and the number of RGB digital fiber optic sensors 5 is consistent with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com