Magnetic area closing type iron remover

A closed type, iron remover technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of inconvenient daily maintenance, high use cost, high failure rate, etc., and achieve low magnetic field demagnetization rate and low use cost , the effect of low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

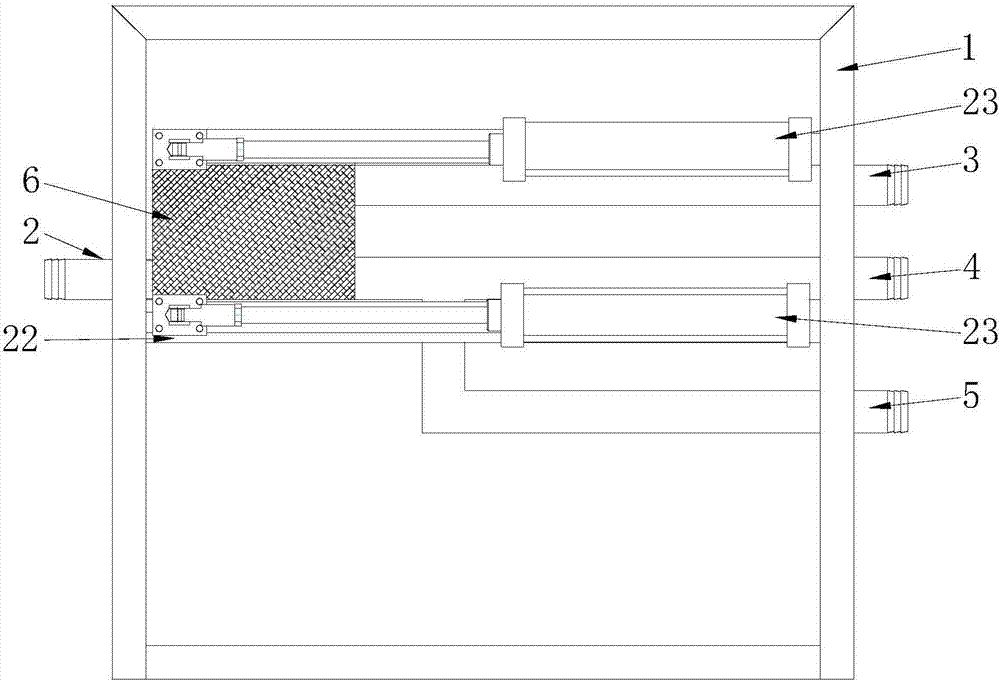

[0038] Such as figure 1 In the iron remover shown, the frame 1 is fixed with a working chamber, and the working chamber can adopt an existing conventional design. The bottom of the working chamber is provided with a slurry inlet and a return port, and the top of the working chamber is provided with a slurry outlet. The slurry inlet is connected to the pulp feeder through the feed pipeline 2 , the slurry outlet is connected to the stocker through the discharge pipeline 3 , and the return port is connected to the pulp feeder through the return pipeline 4 . In addition, a slag discharge pipeline 5 leads out from the return pipeline, which is used to discharge the waste water in the working chamber. Corresponding pipeline valves are respectively installed in each pipeline.

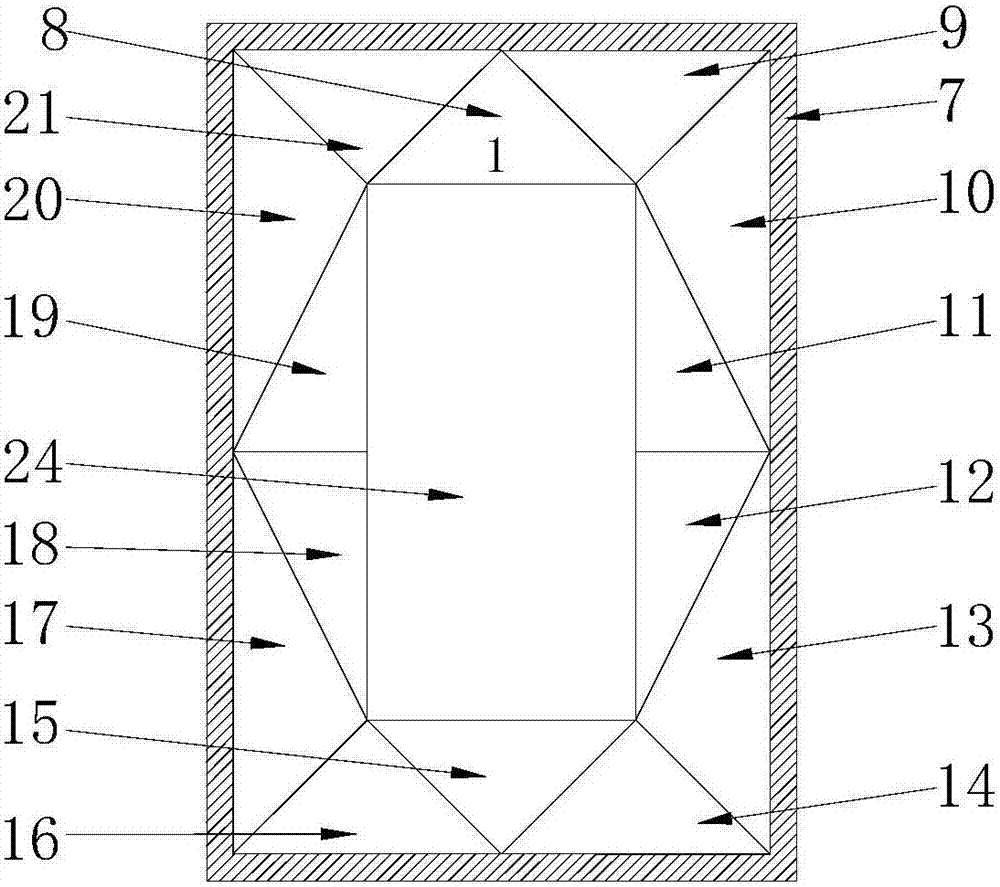

[0039] Such as figure 1 , 2 As shown, a permanent magnet iron removal device 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com