Composite air brick for steel ladle and preparation method thereof

A breathable brick and composite technology, which is applied in casting equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing the service life of breathable bricks, affecting the air permeability of breathable bricks, and steel penetration of breathable channels, so as to reduce the amount of use, Save the use of kiln equipment and gas, and ensure the blowing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

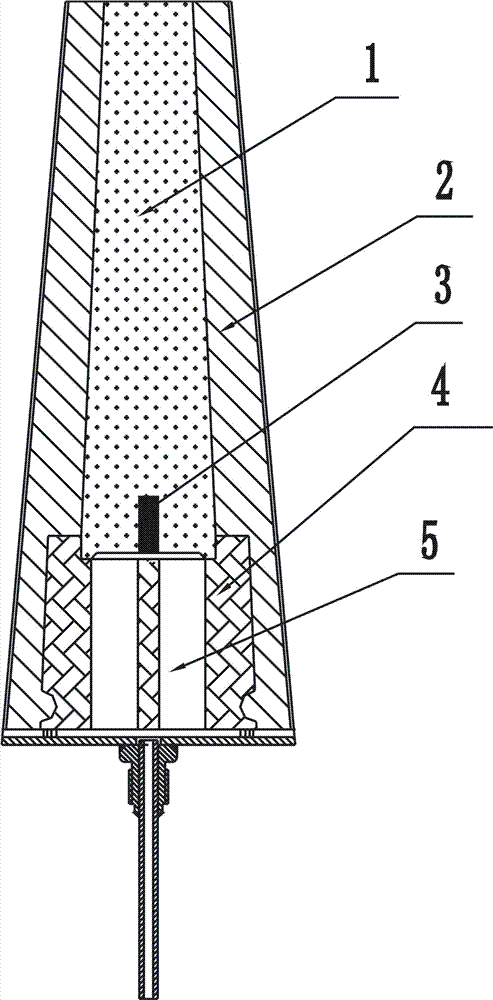

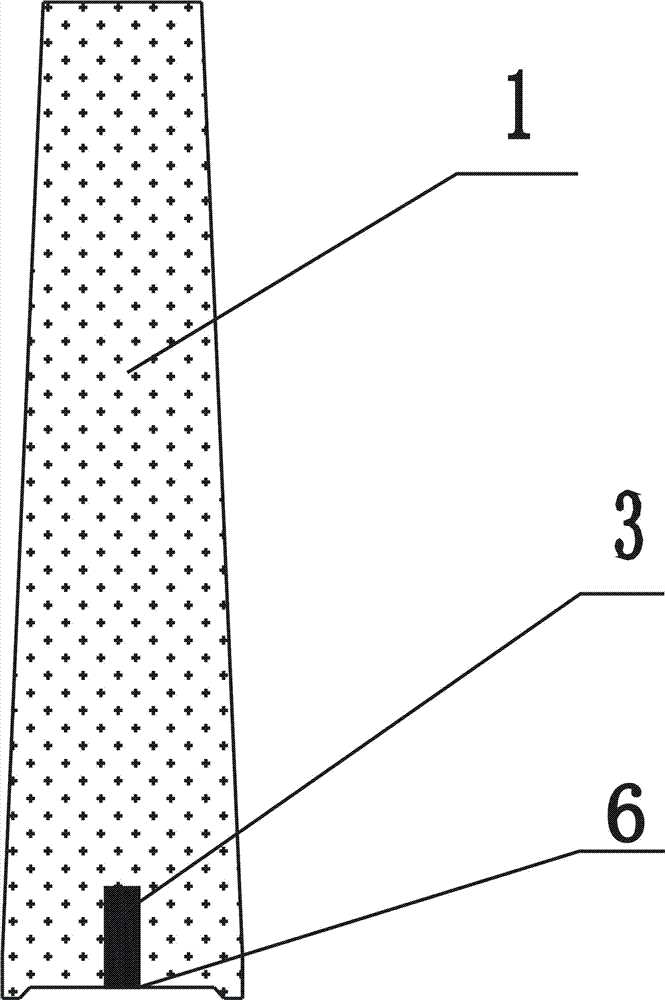

[0040] A method for preparing a composite air-permeable brick for a ladle, the method specifically comprising the following steps:

[0041] (1) Preparation of diffused air-permeable block 1 and diffused brick base 4:

[0042] The dispersing air-permeable block 1 adopts a machine-pressed molding process, and is used after being dried and fired;

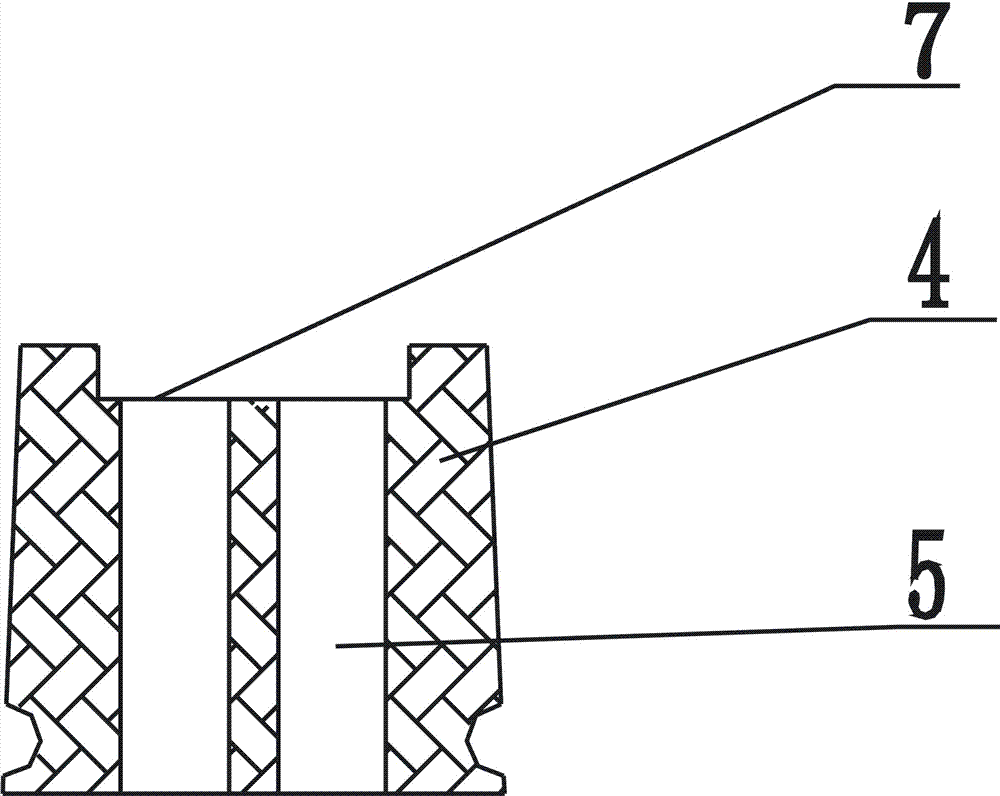

[0043] The dispersed brick base 4 adopts pouring molding technology or machine pressing molding technology, after being cured and dried, it is fired at high temperature, and then cooled to room temperature with the furnace for standby; the high temperature firing step is: rapidly heating up to 300°C and hold for 5 hours; heat up to 1200°C at a rate of 120°C / hour and hold for 4 hours; heat up to 1300°C at a rate of 180°C / hour and hold for 6 hours; heat up to 25°C / hour 1550°C, keep warm for 15 hours and then cool with the furnace;

[0044] (2) Installation of diffused ventilation block 1 and diffused brick base 4:

[0045] A. Pour ref...

Embodiment

[0058] (1) Preparation of diffused air-permeable block 1 and diffused brick base 4:

[0059] The diffused air-permeable block 1 adopts a machine press molding process with a pressure of 15 MPa, and is ready for use after being dried and fired;

[0060] The dispersed brick base 4 adopts casting molding process or machine pressing molding process, after curing, drying, and firing at high temperature, the high-temperature firing step is: rapidly raising the temperature to 300°C at a rate of 35°C / hour, and keeping it warm for 5 hours; Raise the temperature to 1200°C at a rate of 120°C / hour and keep it for 4 hours; raise the temperature to 1300°C at a rate of 180°C / hour and keep it for 6 hours; raise the temperature to 1550°C at a rate of 25°C / hour and keep it for 15 hours , after cooling to room temperature with the furnace for later use;

[0061] (2) Installation of diffused ventilation block 1 and diffused brick base 4:

[0062] A. Pour refractory mud into the hole in the midd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com