A structure with coupled forces between inclined columns and long-span roofs

A large-span, inclined column technology, applied in truss structures, beams, roofs, etc., can solve the problems of unsatisfactory shapes, weaken the overall rigidity of the overall structure, large spans, etc., and achieve the effect of improving safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

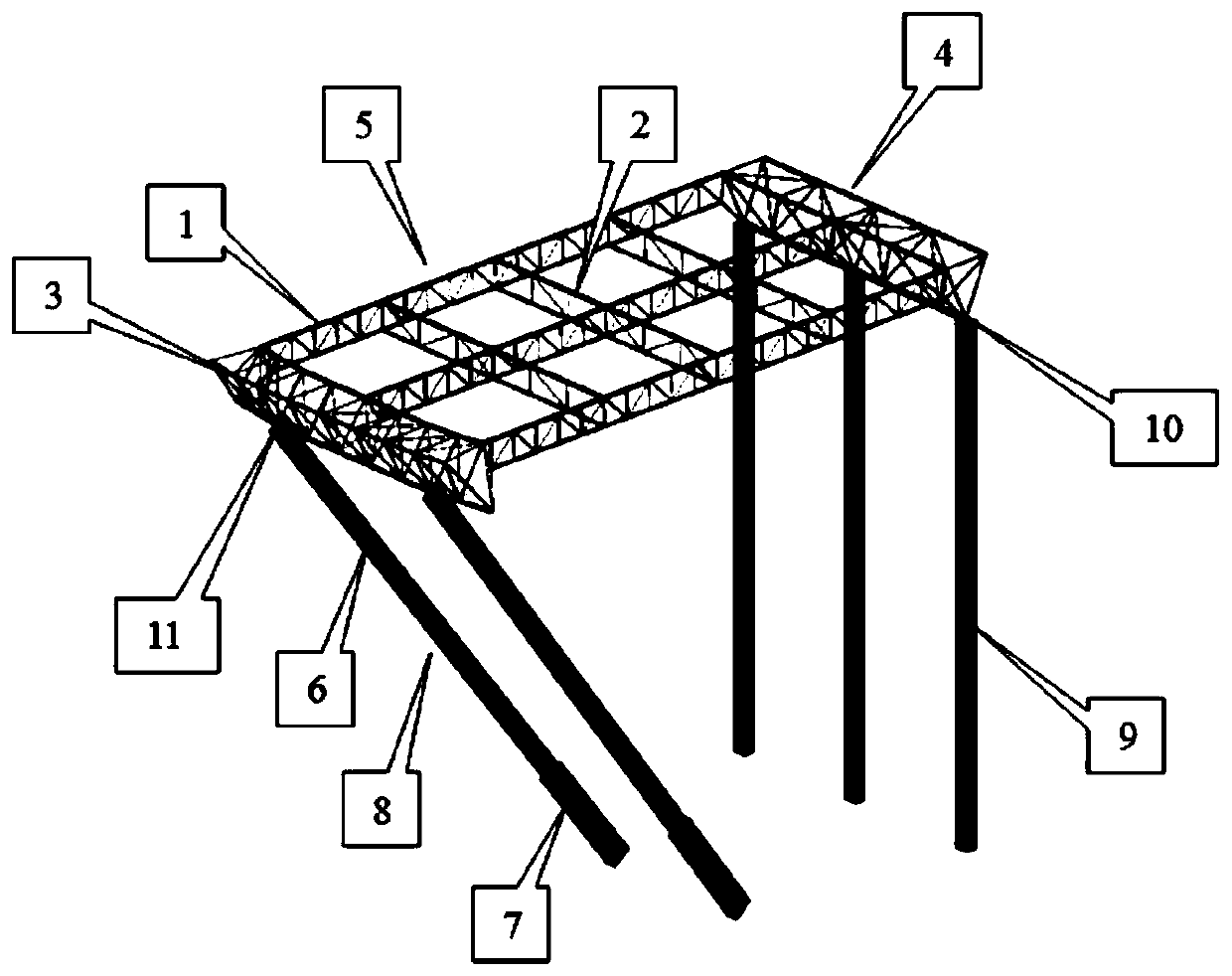

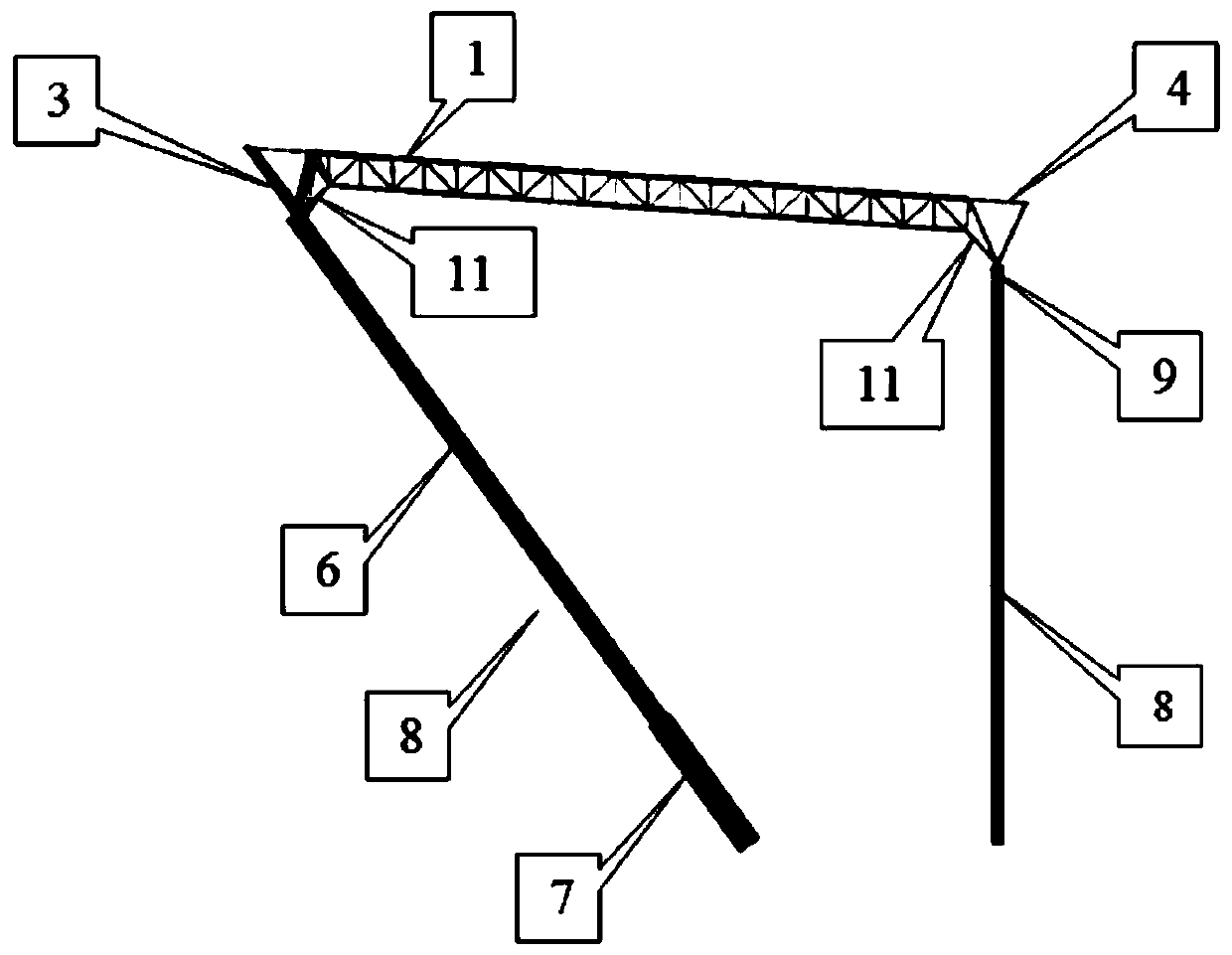

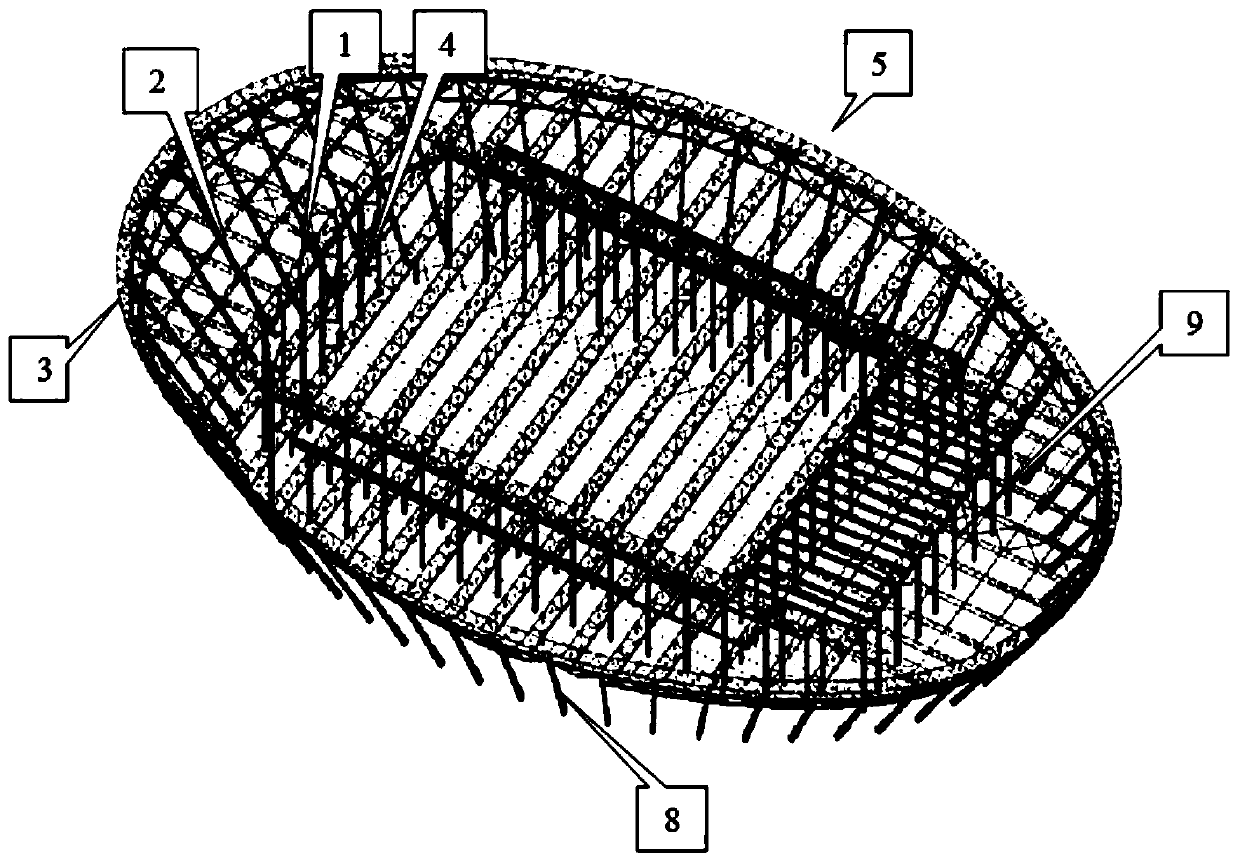

[0018] A stadium project is taken as an example to illustrate the force-bearing structure of the inclined column and the large-span roof of the present invention.

[0019] ①Firstly, establish the lower section 7 of the peripheral slanted column, the upper section 6 of the slanted column and the straight column 9 in sequence, in which the overall plane is elliptical, and the angle between the 52 slanted columns and the ground is about 50°, which is divergent, as shown in Figure 1 , Figure 2, Figure 3. And the internal frame structure 16, as shown in Figure 4, the internal frame structure 16 and the straight columns can be removed after the strength is reached, and the outer ring slanted columns 8 can only be removed after the large-span steel roof 5 is completely installed. Among them, when the slanted column is only calculated separately with the substructure, the roof is applied to the top of the slanted column as a load, and the maximum displacement of the column top is 125m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com