A sensor configuration optimization method for spacecraft folding structure health monitoring

A technology for health monitoring and sensors, applied in design optimization/simulation, instrumentation, geometric CAD, etc., to solve problems such as inconsistent reliability and low sensor reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

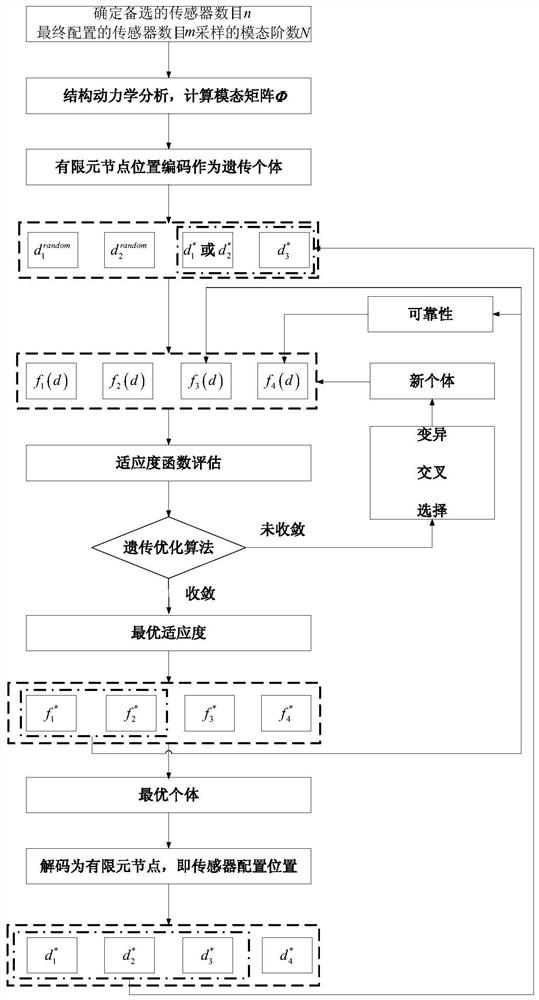

[0040] The present invention is a sensor configuration method based on interval robust optimization for structural health monitoring, such as figure 1 As shown, the steps are as follows:

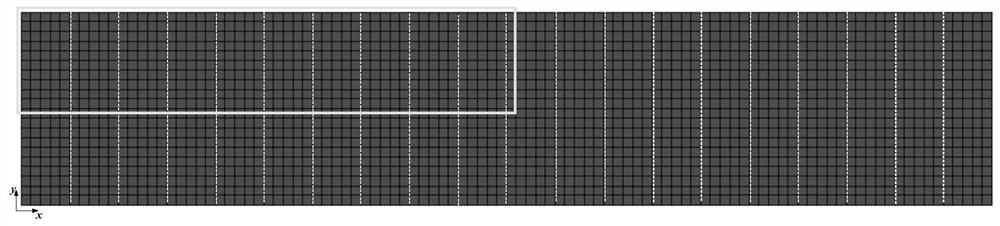

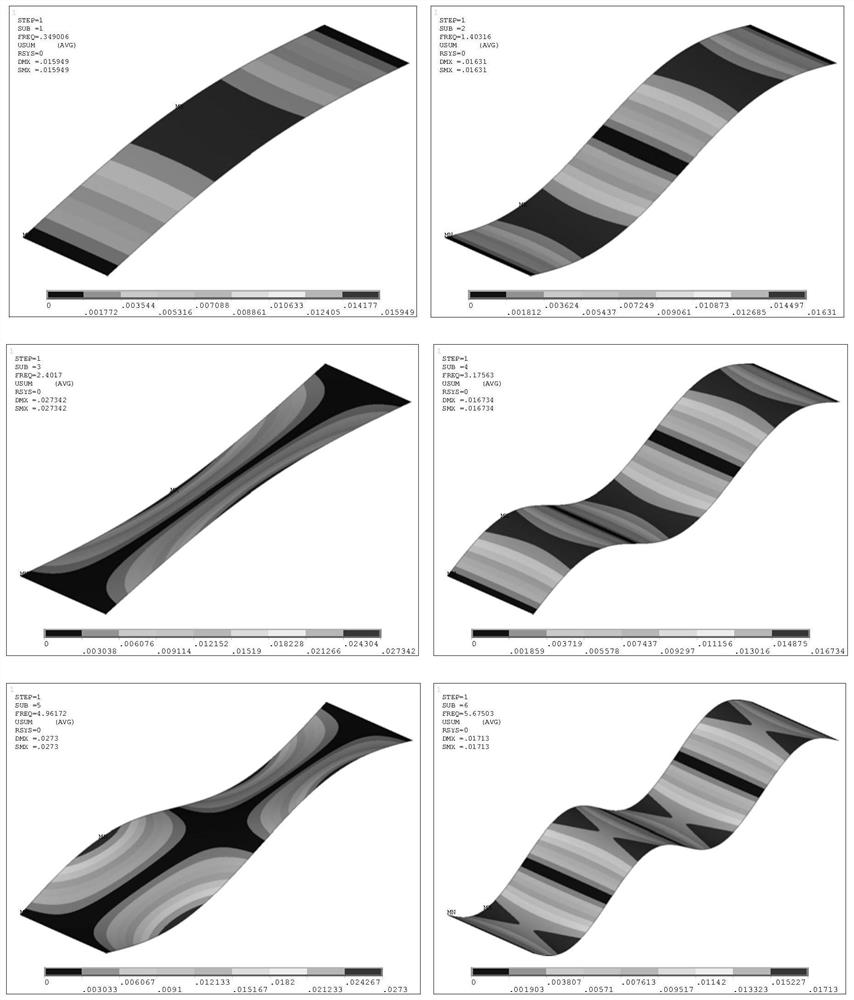

[0041] (1) Consider if figure 2 A 20m×100m antenna expansion module of the shown space solar power plant has a folding and unfolding mechanism every 5m. The thickness of the module is 0.15m, Young’s modulus of elasticity is 70GPa, Poisson’s ratio is 0.3, and the surface density of the board is 4kg / m 2 . Discretize with a quadrilateral plate unit with a side length of 1m, with a total of 2121 nodes and 2000 units. The boundary conditions are simply supported on both sides of 20m, free on both sides of 100m, and the number of sensors is 40. Considering that the sensors should be arranged in places with large modal energy And it does not affect the position of the ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com