Glass electric kettle and lampshade fixing structure thereof

A technology for fixing structures and lampshades, which is applied to water boiling appliances, kitchen utensils, household appliances, etc. It can solve the problems of large assembly gap between the lampshade and the bottom of the glass pot body, excessive tolerance of the lampshade, and large tolerance, so as to simplify assembly , improve the yield, improve the effect of radial strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

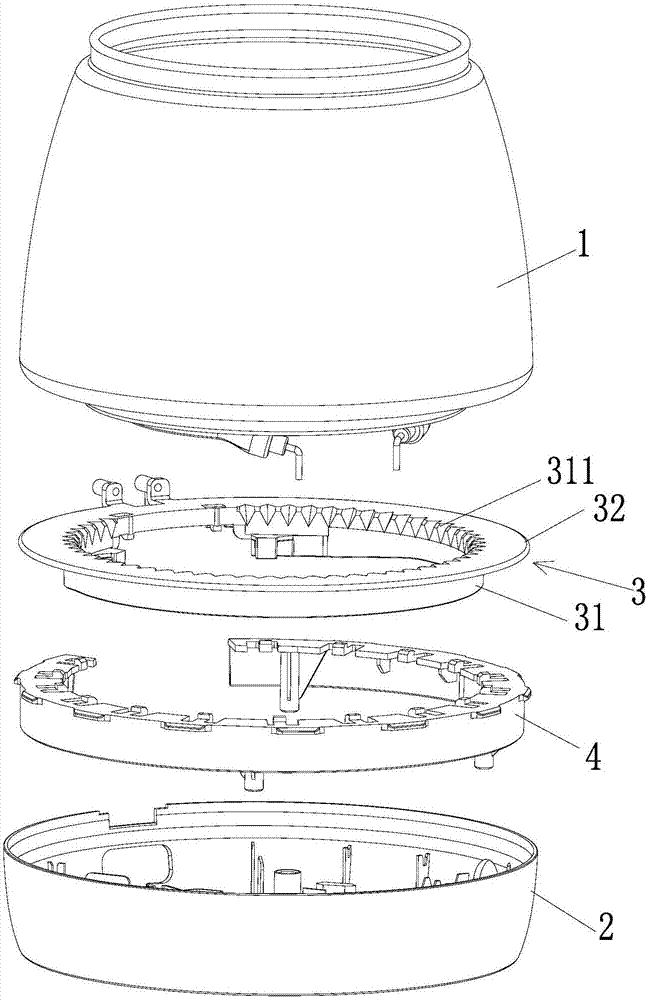

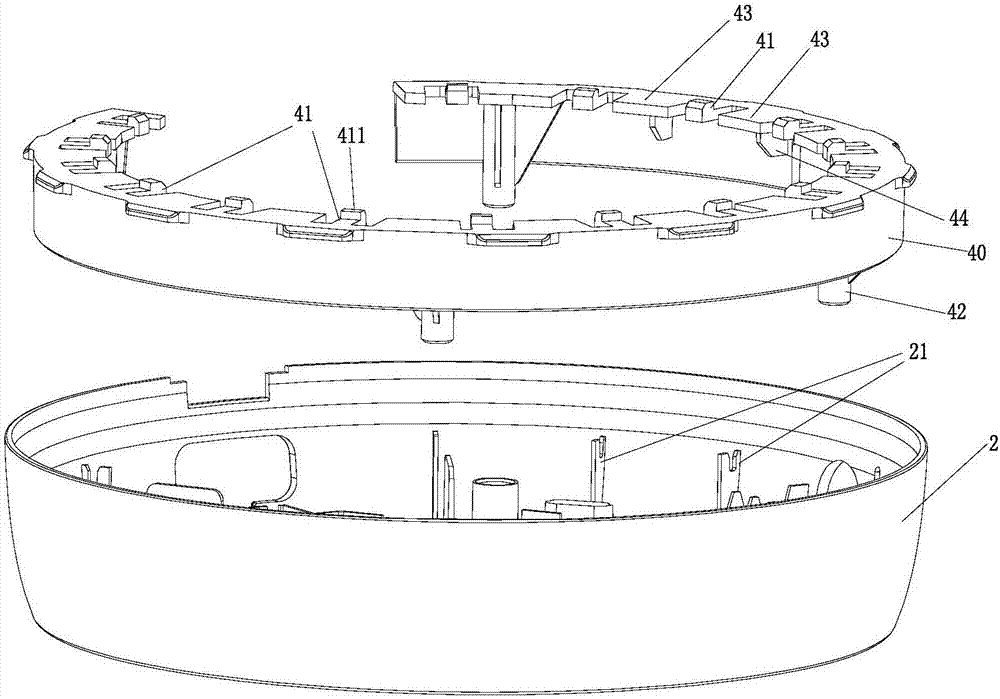

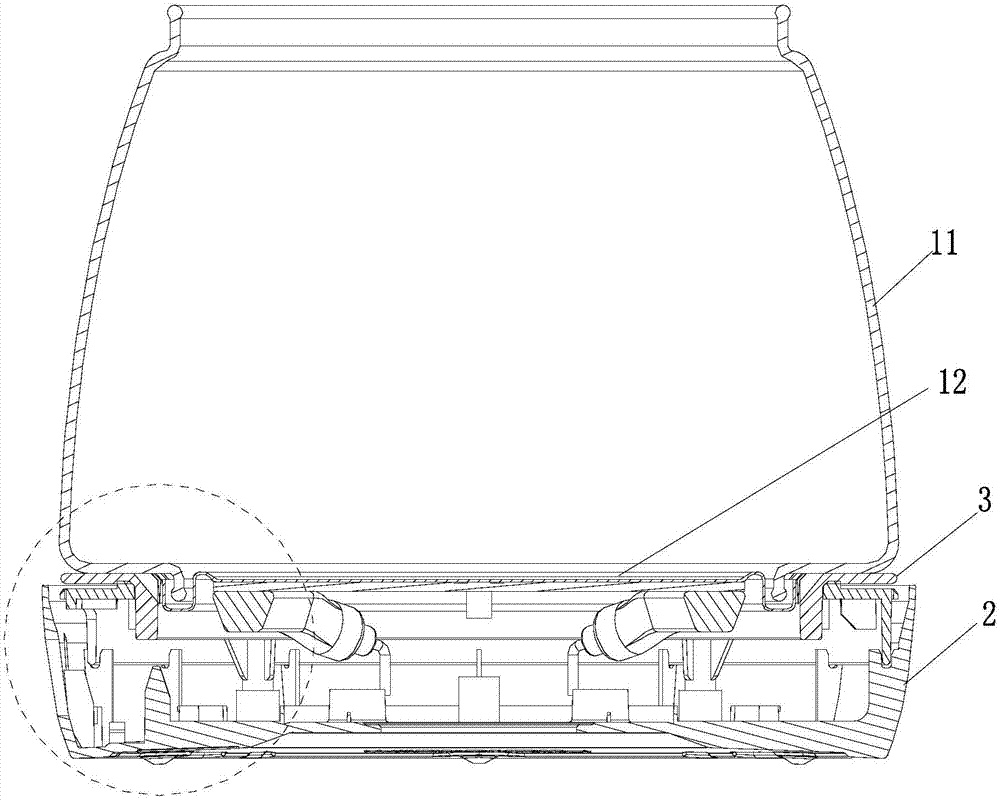

[0023] Below with the accompanying drawings Figure 1 to Figure 4 And embodiment the present invention is described further.

[0024] The present invention proposes a glass electric kettle at least comprising a glass body 1, a base 2, a lampshade 3 embedded with an indicator light, an elastic bracket 4 fixed in the base 2, and a heating device arranged on the base 2. The lampshade 3 is placed on the bottom of the glass kettle body 1 .

[0025] The glass kettle body 1 includes a glass container 11 and a heating seat 12 , and the lower end of the glass container 11 is embedded in the heating seat 12 . The heating seat 12 is located above the heating device, and the heat generated by the heating device is conducted to the liquid in the glass container 11 through the heating seat 12 to realize the heating function.

[0026] The lampshade 3 is arranged in a ring shape, and one or more indicator lights are embedded in the lampshade 3, and the indicator lights generally adopt LED l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com