Wall corner and method for manufacturing the same

A manufacturing method and corner technology, applied in building construction, covering/lining, construction, etc., can solve the problems of poor firmness and durability of house corners, time-consuming, labor-intensive and material-consuming, and achieve convenient construction, good overall performance, and good appearance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

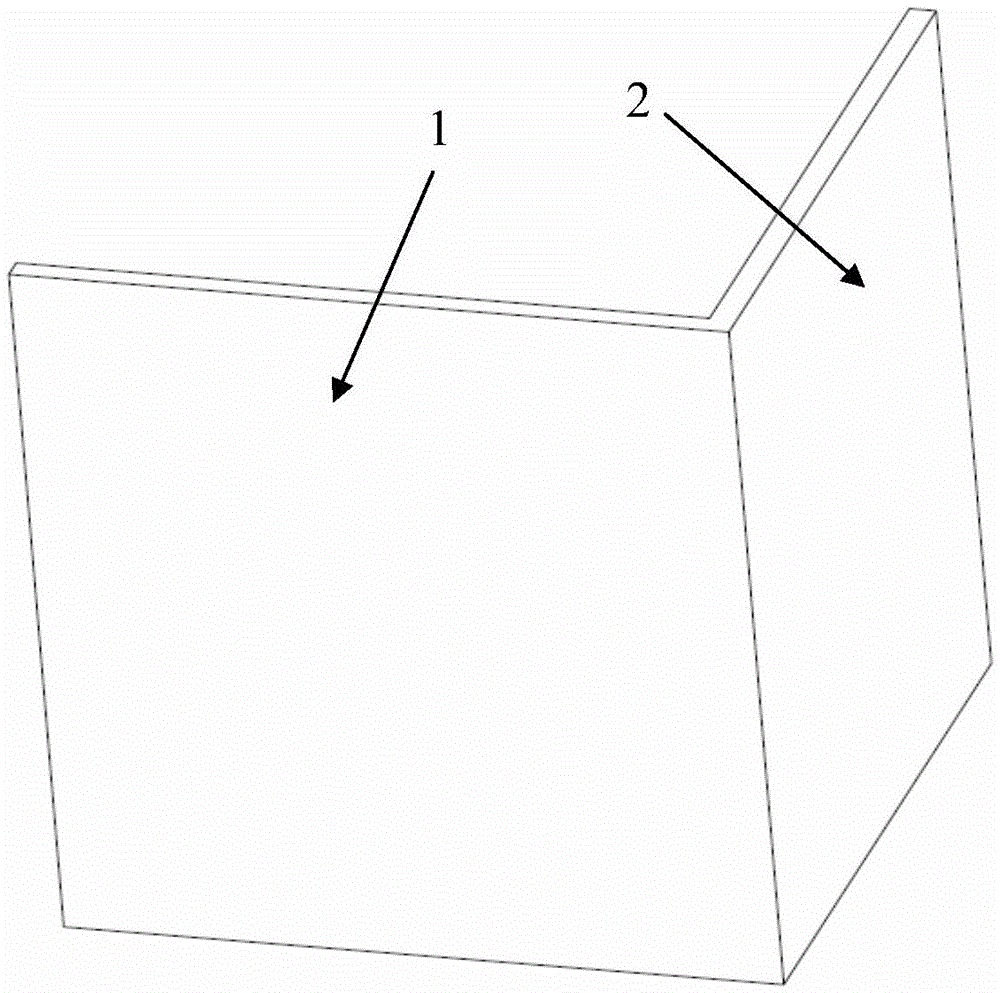

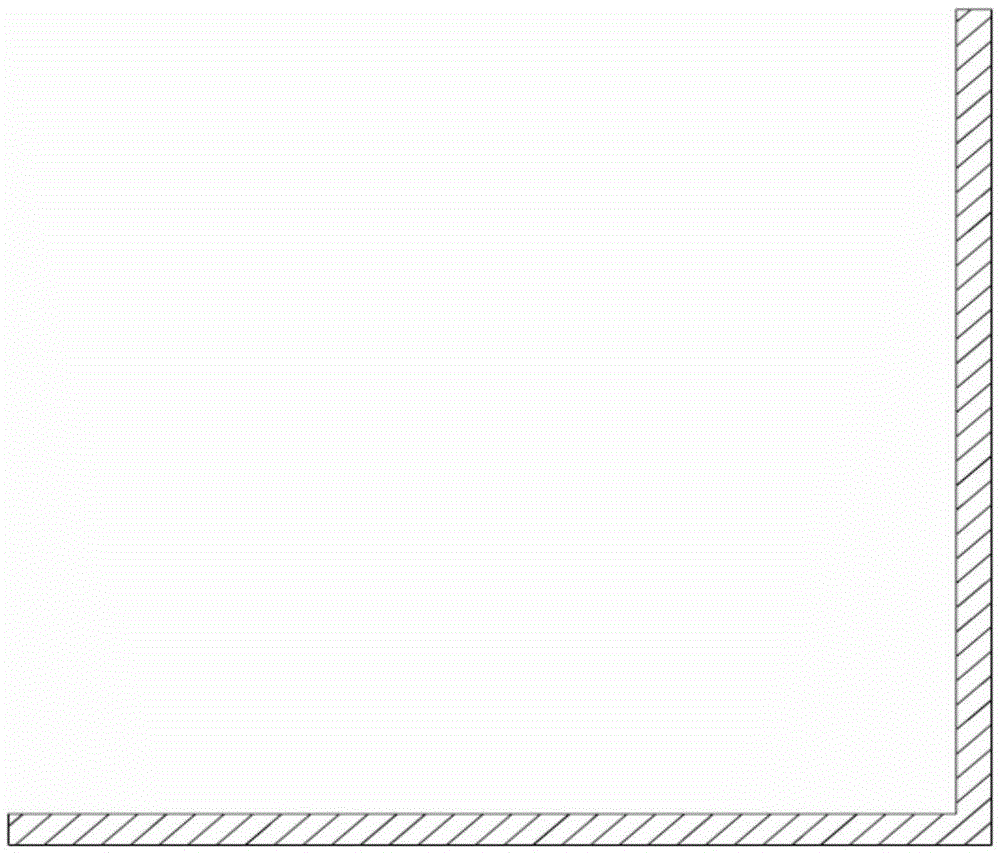

[0027] Such as figure 1 , 2 As shown, the wall corner of this embodiment is used to be located at the corner between the two walls of the house (such as the corner of the outer wall, the corner of the inner wall or other corners on the wall of the house), and the integrated structure, which includes a first wall panel part 1 and a second wall panel part 2, the angle between the first wall panel part 1 and the second wall panel part 2 corresponds to the angle between the two walls, and the first wall panel part 1 is connected or assembled with one wall, and the second wall panel part 2 is connected or assembled with the other wall. Due to the integrated structure of the corner of the wall, the splicing gap only appears in the first wall panel part 1 and the second wall panel part 2 The joint with the wall of the house avoids the joint gap at the corner of the house, and effectively improves the integrity, sturdiness and aesthetics of the corner of the house.

[0028] A pre-e...

Embodiment 2

[0032] The material ratio of the wall corner in this embodiment is: 1 cement, 1.5 mine waste, 0.005 lignocellulose, 0.2 straw powder, 0.005 water reducing agent, 0.005 alkali-resistant glass fiber, 0.03 concrete waterproofing agent, 0.45 water.

Embodiment 3

[0034] The material ratio of the wall corner in this embodiment is: 1 cement, 2.5 mine waste, 0.0055 lignocellulose, 0.22 straw powder, 0.01 water reducer, 0.01 alkali-resistant glass fiber, 0.05 concrete waterproofing agent, 0.5 water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com