Uprighting bearings for downhole drilling motors

A technology of righting bearings and bearings, which is applied in the direction of drilling drive devices, casings/covers/supports, electromechanical devices, etc. in boreholes, can solve the problems that the bearing capacity of righting bearings cannot meet the needs, and achieve axial space saving, The effect of increasing the life and increasing the diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

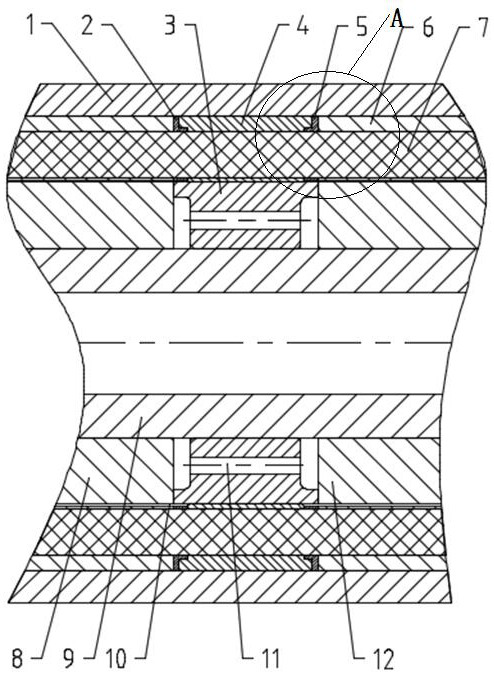

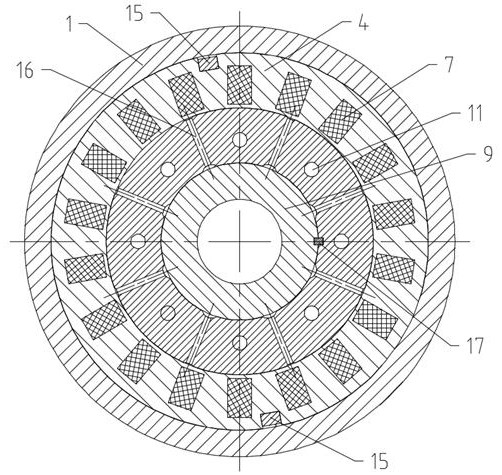

[0026] As a preferred embodiment of the application, refer to the attached figure 1 , 2 , 3 and 4, the present embodiment discloses:

[0027] The righting bearing for the downhole drilling tool motor includes a bearing static ring and a bearing moving ring. The inner surface of the bearing static ring is a closed structure, forming the friction surface of the static ring; the outer surface of the bearing moving ring forms the friction surface of the bearing moving ring, and the friction surface of the moving ring of the bearing and the friction surface of the static ring The diameter is the same as the outer diameter of the rotor core; the outer surface of the static ring of the centralizing bearing is provided with a positioning groove for the static ring, and the positioning groove of the static ring is matched with the positioning key of the static ring to realize the static ring of the bearing and the stator casing The circumferential positioning between them; the bearin...

Embodiment 2

[0029] As another preferred embodiment of the present application, refer to the attached Figure 1-5 , this example discloses:

[0030] Such as figure 1 As shown, the righting bearing for the motor of the downhole drilling tool includes a static bearing ring and a moving bearing ring. The static ring slot for the stator coil to pass through, the inner surface of the bearing static ring is a closed structure, forming a static ring friction surface; the outer surface of the bearing dynamic ring forms the bearing dynamic ring friction surface, and the bearing dynamic ring friction surface and the static ring The diameter of the friction surface is the same as the outer diameter of the rotor core; the outer surface of the static ring of the centralizing bearing is provided with a positioning groove for the static ring, and the positioning groove of the static ring is matched with the positioning key of the static ring to realize the static ring of the bearing and the Circumferen...

Embodiment 3

[0032] As another preferred embodiment of the present application, refer to the attached Figure 1-5 , this example discloses:

[0033] The motor straightening bearing disclosed in the present application is a sliding bearing device used for motors with a high aspect ratio (motor length / motor rotor diameter) such as submersible motors or downhole drilling motors. It is mainly composed of two parts: fixed part and rotating part.

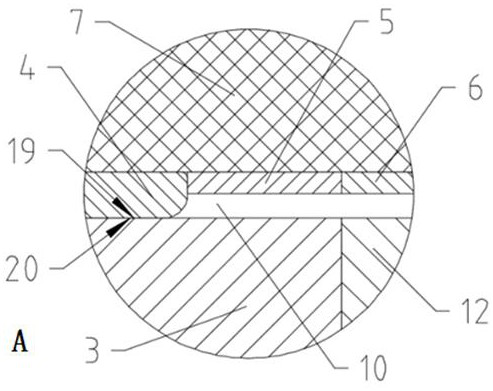

[0034] The fixed part includes: the static bearing ring 4, the left positioning ring 2, the right positioning ring 5 and other parts. Among them, the bearing static ring 4 is made of a whole piece of non-magnetic or weak magnetic conductive material, and there are several static ring notches 14 on it, and the stator coil 7 can pass through the static ring notches 14 directly, and the inner surface is a closed structure , forming the static ring friction surface 19; the static ring of the bearing is provided with a positioning groove 13, and the circum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com