Glass electric kettle and its lampshade fixing structure

A technology of electric kettle and glass, which is applied in the field of glass electric kettle and its lampshade fixing structure, which can solve the problems of large assembly gap between the lampshade and the bottom of the glass kettle body, excessive tolerance of the lampshade, and poor appearance, so as to simplify assembly and improve yield , Improve the effect of radial strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

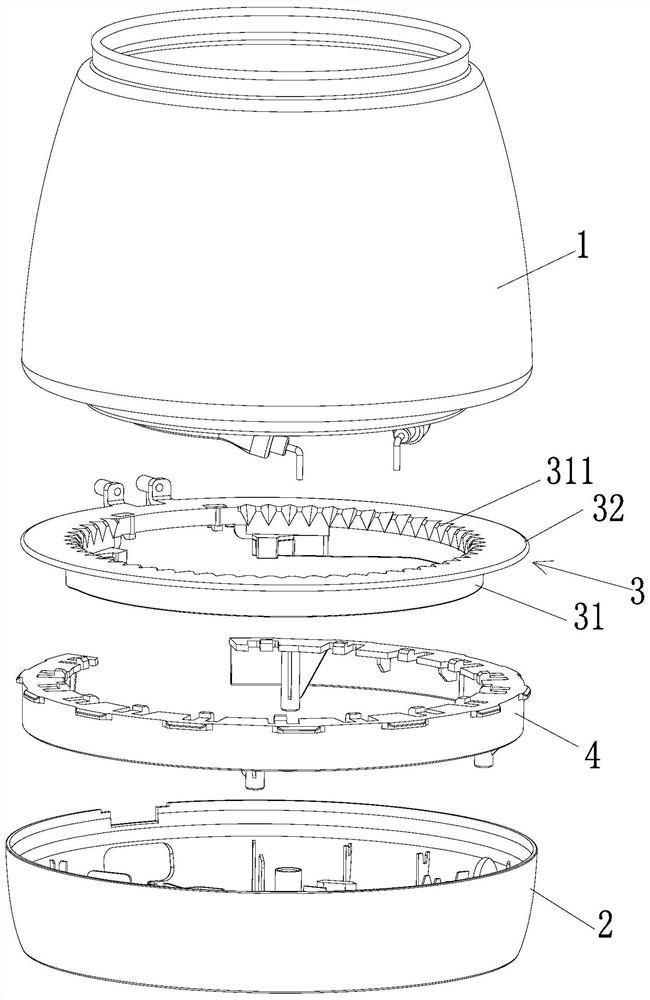

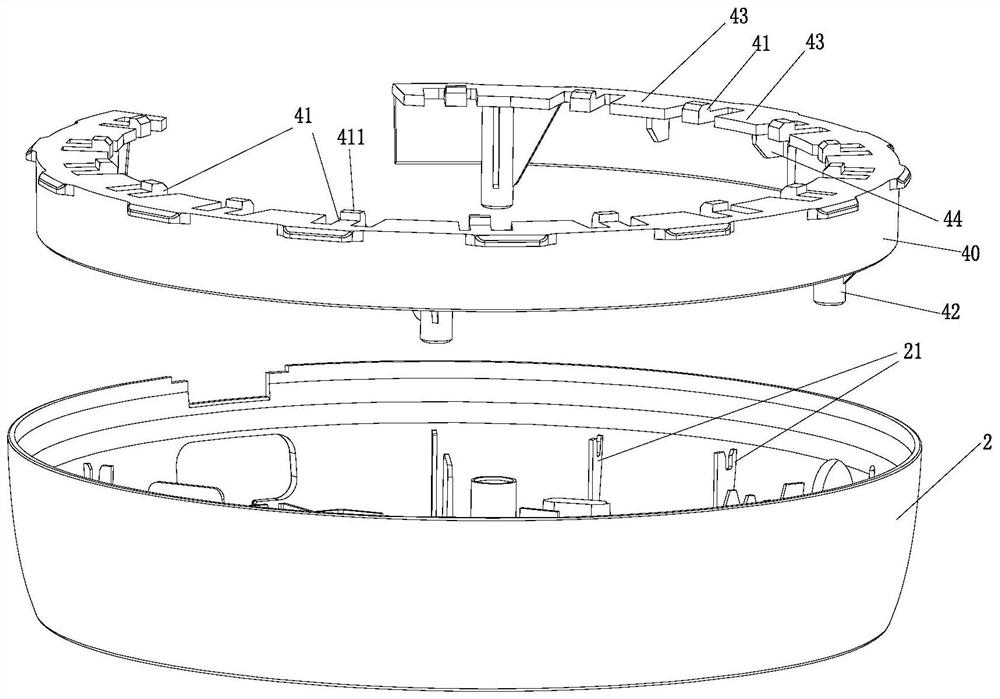

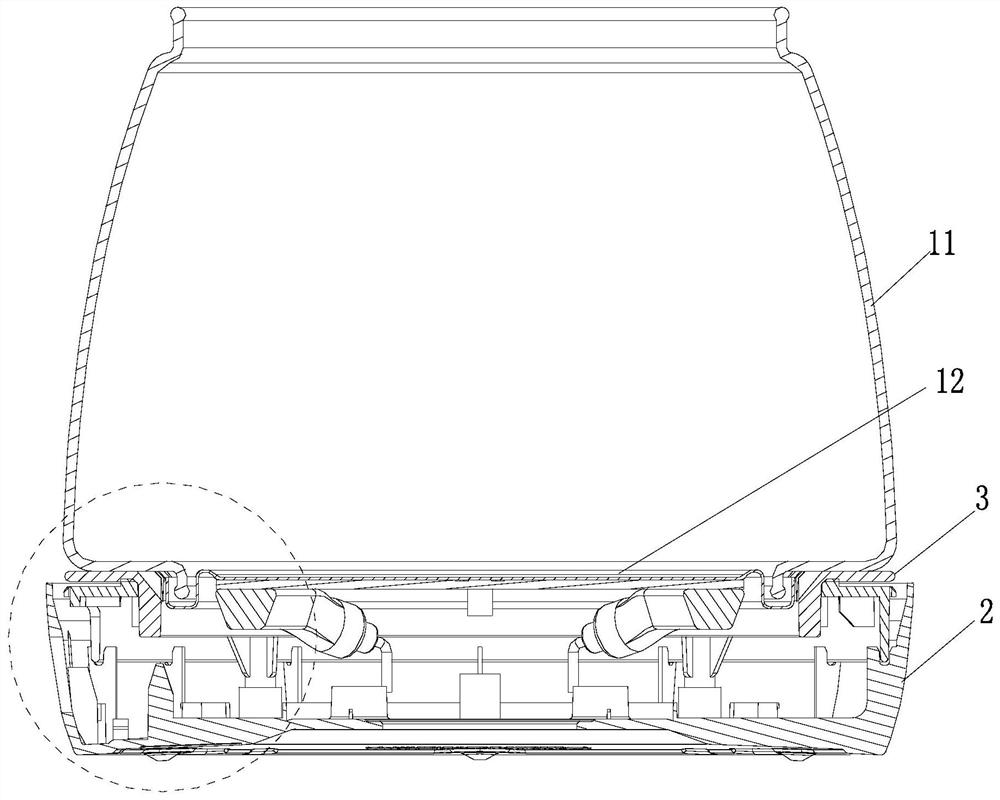

[0023] Below in conjunction with the accompanying drawings Figure 1 to Figure 4 The present invention is further illustrated with examples.

[0024] The present invention proposes a glass electric kettle at least comprising a glass kettle body 1, a base 2, a lampshade 3 with an indicator light embedded therein, an elastic support 4 fixed in the base 2, and a heating device arranged on the base 2. The lampshade 3 is pressed on the bottom of the glass pot body 1 .

[0025] The glass pot body 1 includes a glass container 11 and a heating base 12 , and the lower end of the glass container 11 is embedded in the heating base 12 . The heating seat 12 is located above the heating device, and the heat generated when the heating device works is conducted to the liquid in the glass container 11 through the heating seat 12 to realize the heating function.

[0026] The lampshade 3 is arranged in a ring shape, and one or more indicator lights are embedded in the lampshade 3, and the indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com