Vertical type air processor

An air processor, vertical technology, applied to chemical instruments and methods, dispersed particle filtration, combined devices, etc., to achieve good adhesion effect, novel device structure design, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

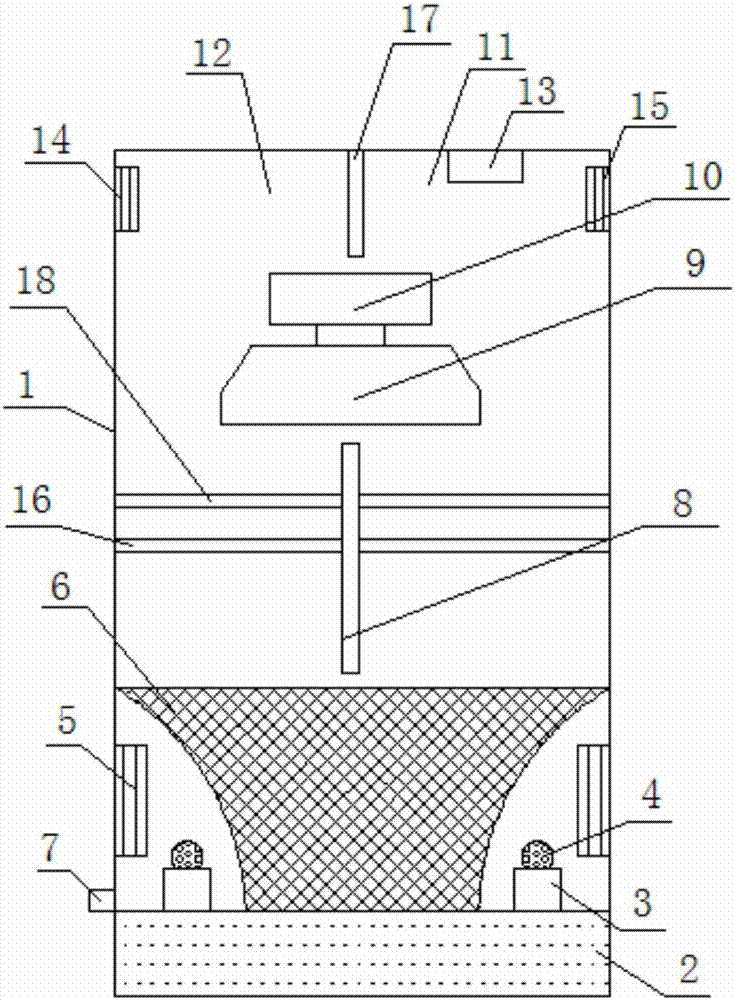

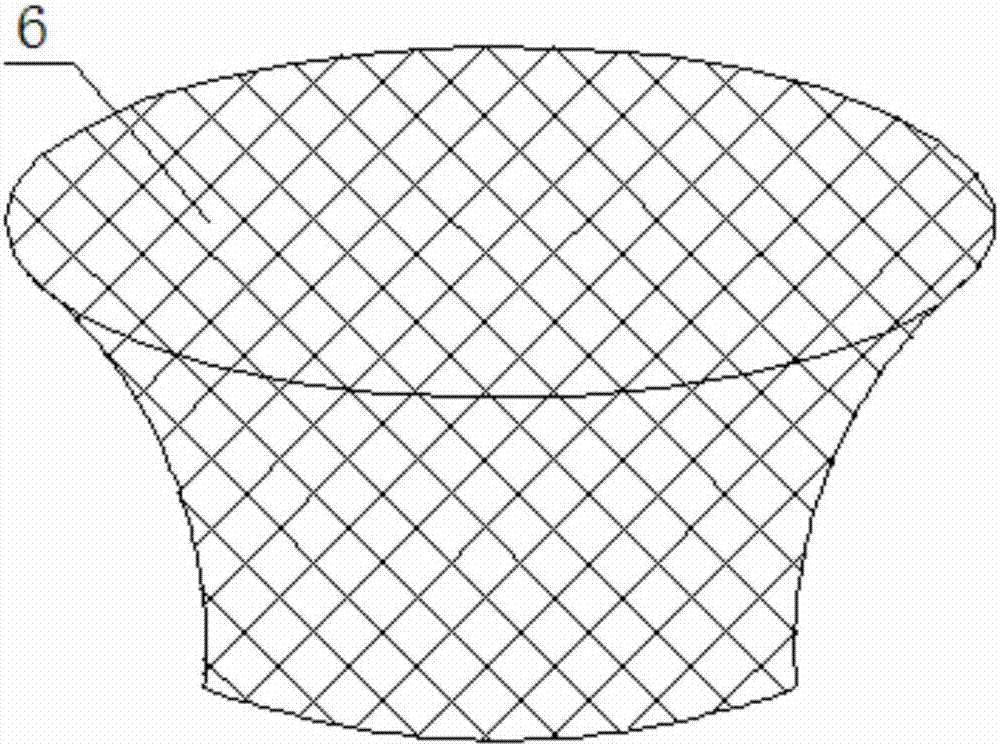

[0027] Such as Figure 1 to Figure 2 As shown, the present invention provides a vertical air handler, comprising: a box body 1, a water storage tank 2 arranged at the bottom of the box body 1, an activated carbon filter 6 arranged on the water storage box 2, an activated carbon filter 6 arranged at the water storage box 2 several sprinklers 3 located above and around the activated carbon filter 6, the air inlet 5 arranged on the box body 1 and located on the side of the activated carbon filter 6, the water outlet located on the box body 1 and located below the air inlet 5 Valve 7, the electrostatic filter screen 16 located at the top of the active carbon filter 6, the antibacterial cotton net 18 located on the electrostatic filter screen 16, the first partition 8 vertically located in the middle of the electrostatic filter screen 16, and the antibacterial cotton net 18 The fan 9 above, the motor 10 connected to the top of the fan 9, the second partition 17 located above the mo...

Embodiment 2

[0033] A preparation method of a self-cleaning activated carbon filter device for a vertical air processor, the steps are as follows:

[0034] ①, structure and molding

[0035] The self-cleaning activated carbon filter device includes a water storage tank and an activated carbon filter placed on the upper part of the water storage tank. Several water sprayers are arranged above the water storage tank and around the activated carbon filter. The top of the water sprayer is provided with a spherical nozzle; The filter is cylindrical and its diameter gradually increases from bottom to top;

[0036] The supporting base material of the activated carbon filter is carbon steel mesh, which is rolled and welded first and then loaded with activated carbon; the activated carbon is loaded using a pressing process, and the thickness of the loaded activated carbon is 10mm; the water sprayer and the spherical nozzle are made by conventional hardware processing technology into; the material o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com