Environment-friendly building solid waste treatment equipment

A solid waste and processing equipment technology, applied in grain processing, solid separation, dispersed particle filtration, etc., can solve the problems of inconvenient recycling, waste of resources, air pollution, etc., and achieve the effect of improving resource utilization and gas cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

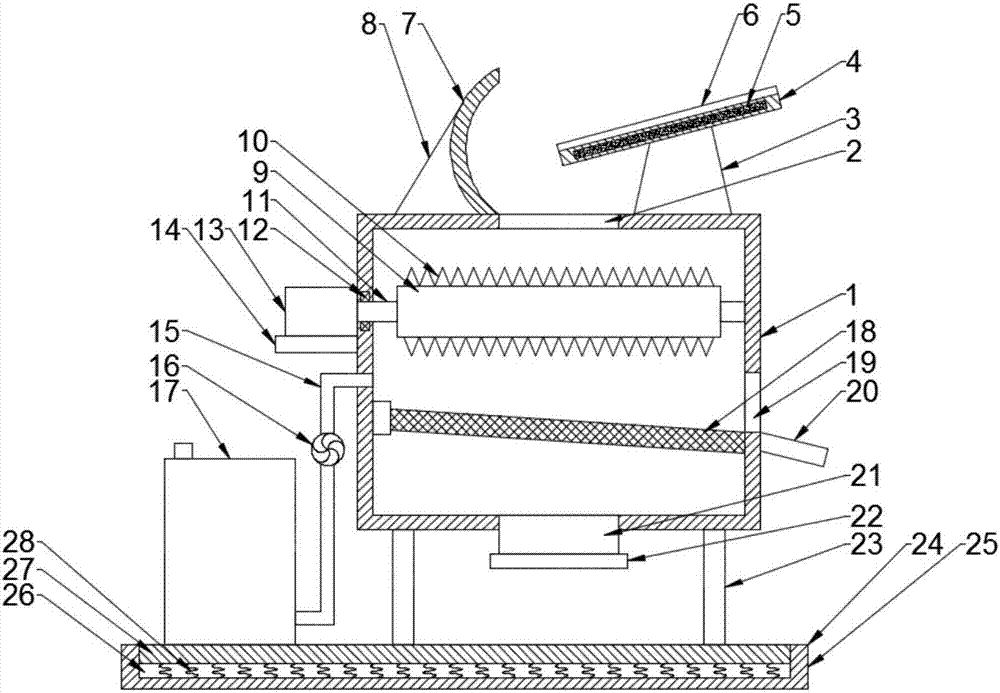

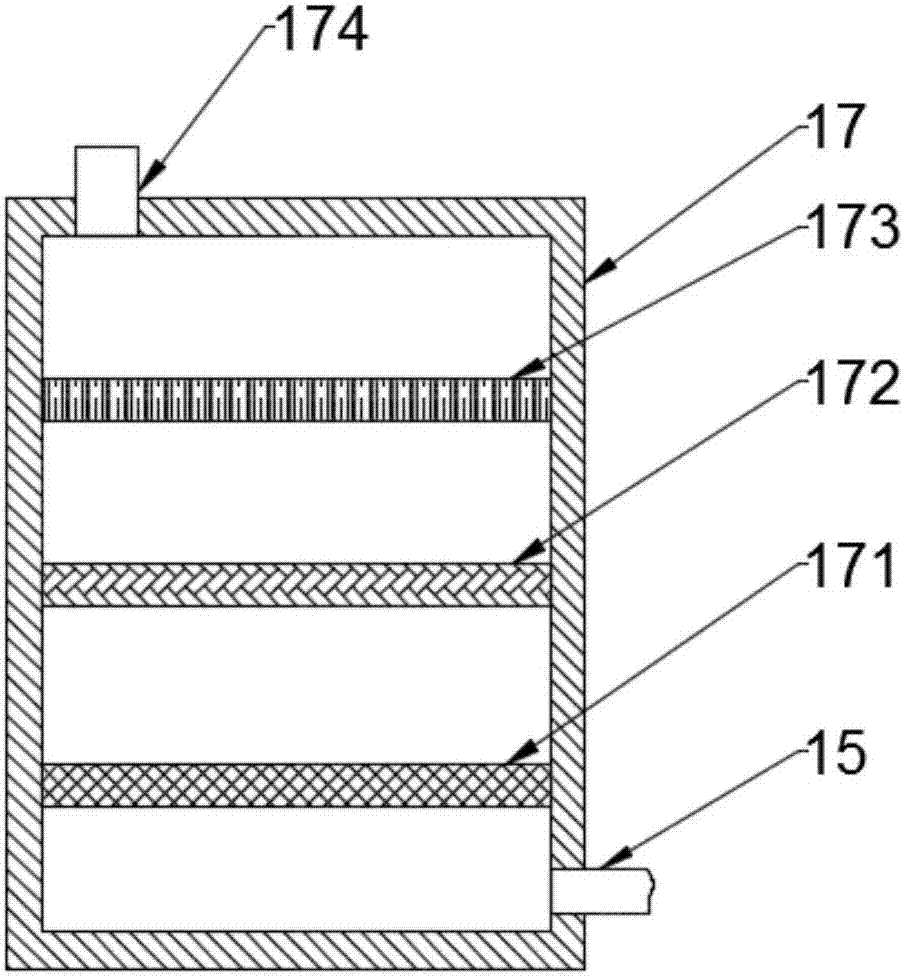

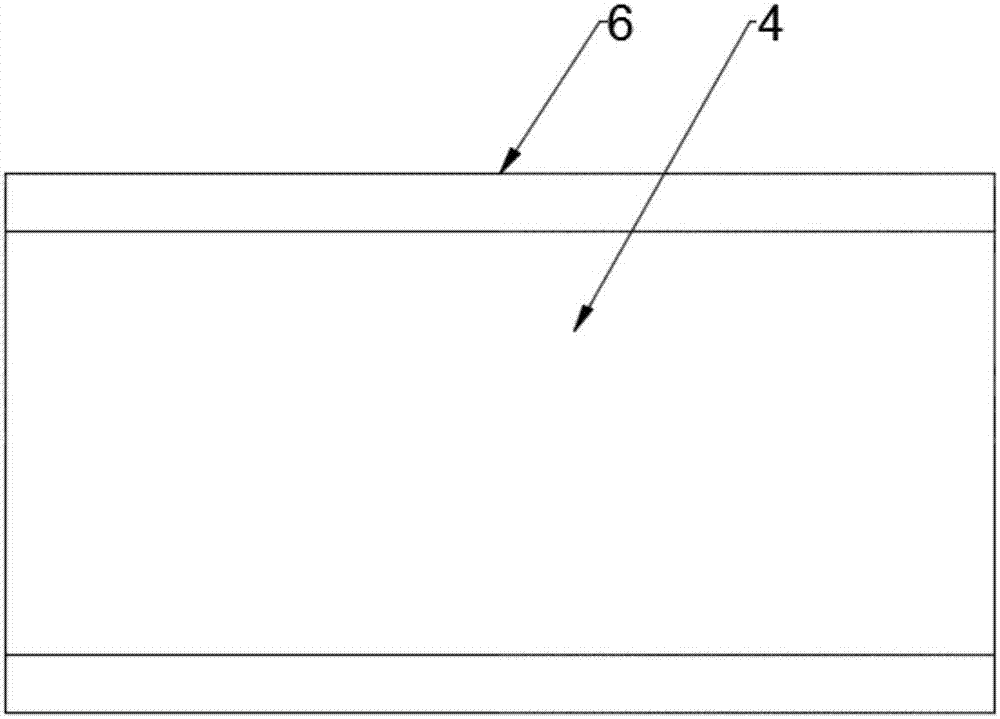

[0018] see Figure 1~3 , a kind of environment-friendly construction solid waste treatment equipment, comprises cabinet 1, purification box 17 and base 24, and the inner cavity top wall of described cabinet 1 is provided with feed hole 2, and the left side of the top opening of described feed hole 2 is fixed Connect the baffle 7, the baffle 7 is an arc-shaped plate, the left end surface of the baffle 7 is provided with a reinforcing rib 8, and the right side of the top opening of the feed hole 2 is provided to match the baffle 7 The material guide plate 4, the material guide plate 4 is inclined, the material guide plate 4 is fixed on the top of the cabinet 1 through the support 3, the material guide plate 4 is provided with a magnetic plate 5, and the magnetic plate 5 is made of natural Made of magnet, the front and rear sides of the guide plate 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com