Timber cutting machine

A wood cutting machine and frame technology, applied in the direction of sawing components, sawing equipment, wood processing equipment, etc., can solve the problems of crushing wood, waste, and wood can no longer be separated from the leather bar, so as to improve work efficiency, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

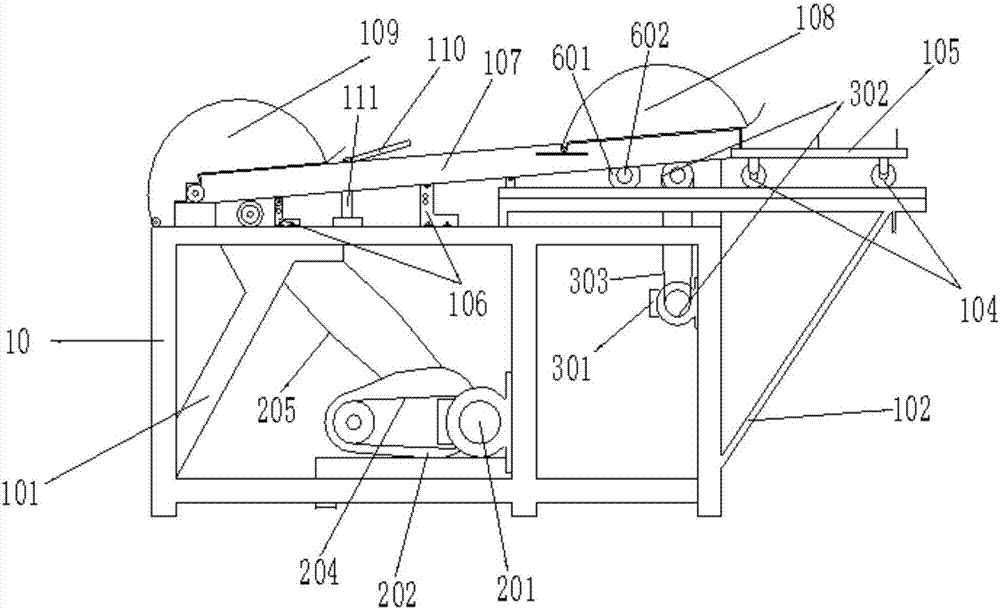

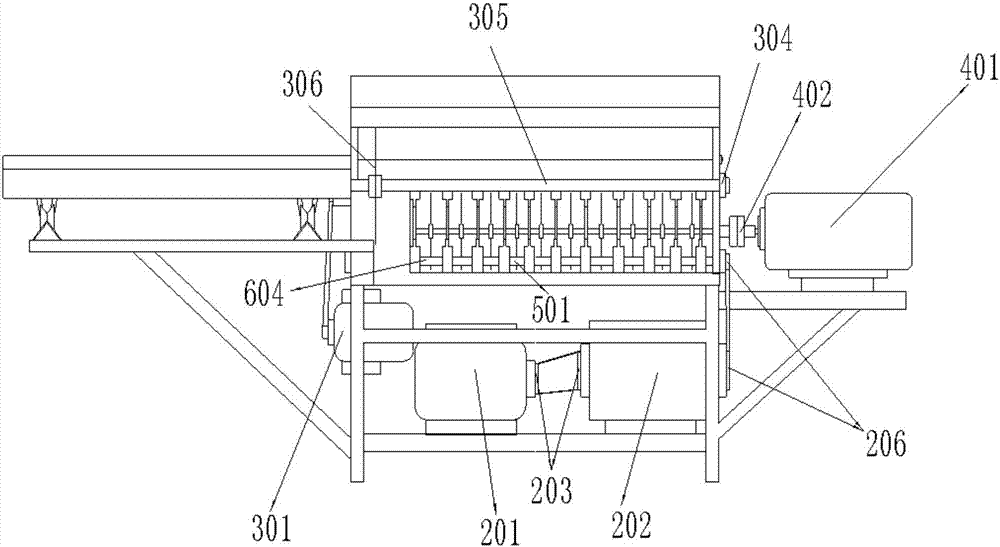

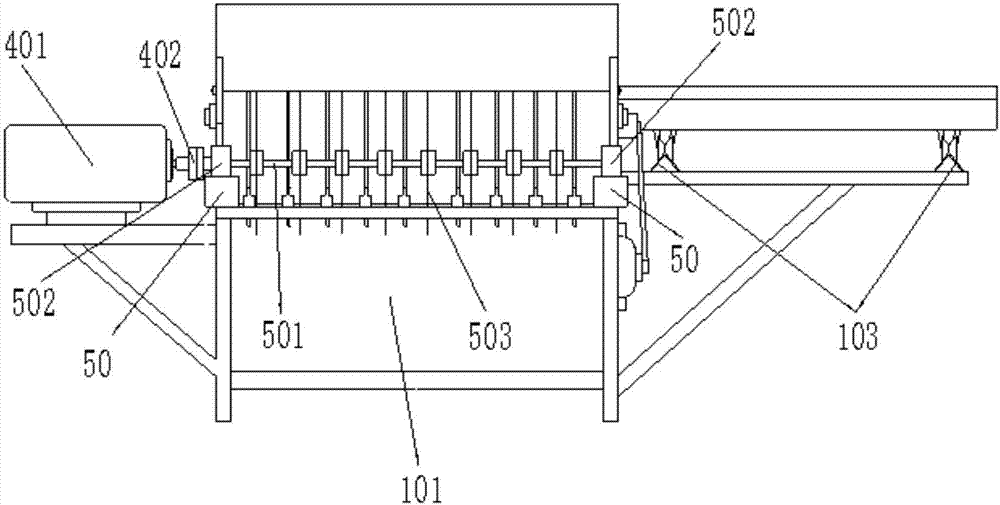

[0031] Such as Figure 1 to Figure 4 As shown, a wood cutting machine is mainly used for cutting wood such as mulberry trees and mulberry trees. It includes a frame 10 on which a workbench is arranged.

[0032]The frame 10 is provided with a transmission mechanism for transporting wood, an active power mechanism for driving the transmission mechanism, a saw mechanism, a saw power mechanism for driving the saw mechanism, a cutting mechanism for cutting wood, and a cutting power mechanism for driving the cutting mechanism. And the feeding mechanism that transports the wood to the feeding end of the transmission mechanism and the material guide plate 101 that connects the cut wood.

[0033] Among them, the transmission mechanism is mainly composed of the first bearing combination, the second bearing combination, the first transmission sprocket set, the second transmission sprocket set and the transmission chain set; the first transmission sprocket set is arranged on the first bea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com