Method for producing low temperature film forming wallpaper

A production method and wallpaper technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve problems such as drumming, easy edge warping of wallpaper, poor film formation of base film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

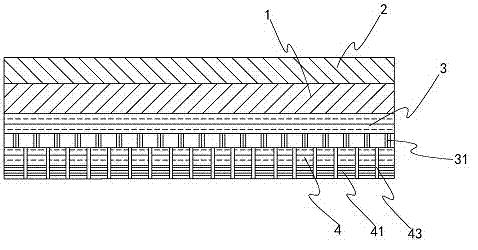

[0020] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0021] The embodiment of the present invention discloses that a method for producing low-temperature film-forming wallpaper includes the following steps in sequence:

[0022] Step (1), preparation of the wallpaper body layer: the white PVC film prepared by the calender is printed on a five-color gravure printing machine with patterns of different colors and patterns through the plate roller and ink, and dried to obtain the wallpaper body layer. The wallpaper body layer is rolled up for use, and the thickness of the wallpaper body layer is 0.2mm;

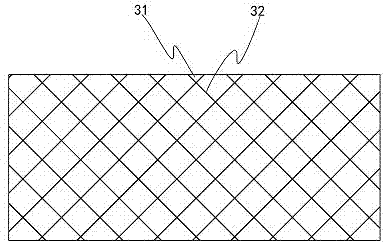

[0023] Step (2), preparation of the resin substrate: stirring and mixing 100-150 parts by weight of polyurethane resin and 12-15 parts by weight of hemp fiber to obtain the resin substrate;

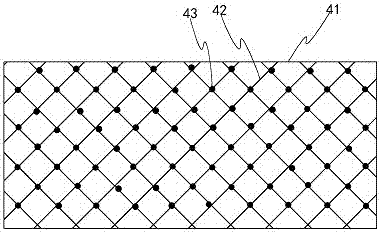

[0024] Step (3), preparation of the first PVC film layer: select a PVC film with a thickness of 0.5mm as the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com