Thermochemically modified starch and its preparation method

A thermochemical, starch technology, applied in starch-derived adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of high transportation cost, unsatisfactory water resistance, complex starch modification process, etc. , to achieve the effect of low transportation cost, easy storage and high transportation efficiency

Active Publication Date: 2019-10-01

NORTHEAST FORESTRY UNIVERSITY

View PDF17 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to solve the technical problems of unsatisfactory water resistance, high transportation cost and complicated starch modification process of existing starch adhesives, and provide a thermochemically modified starch, preparation method and application of thermochemically modified starch Method of preparing adhesive

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

specific Embodiment approach 2

specific Embodiment approach 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Login to View More

Abstract

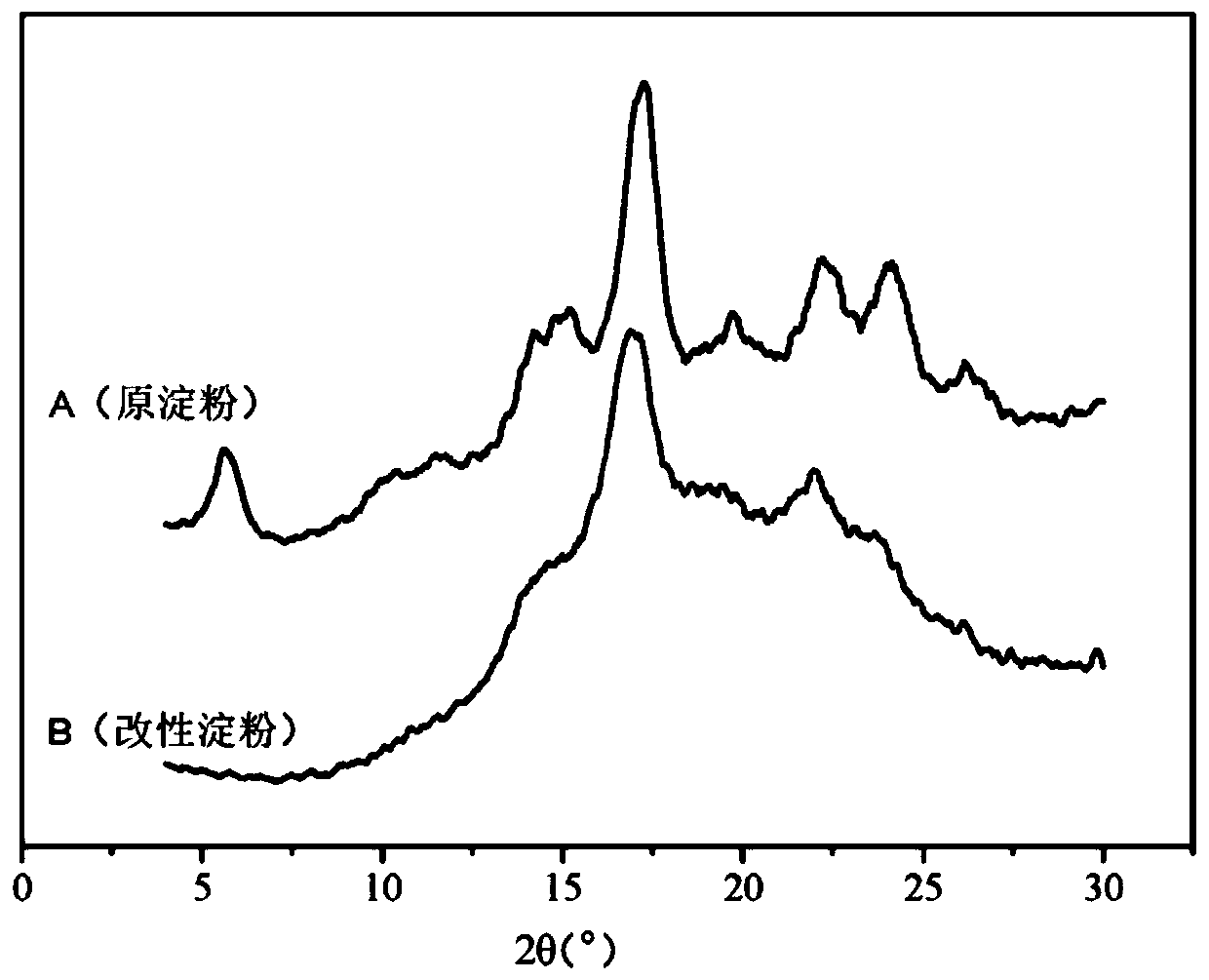

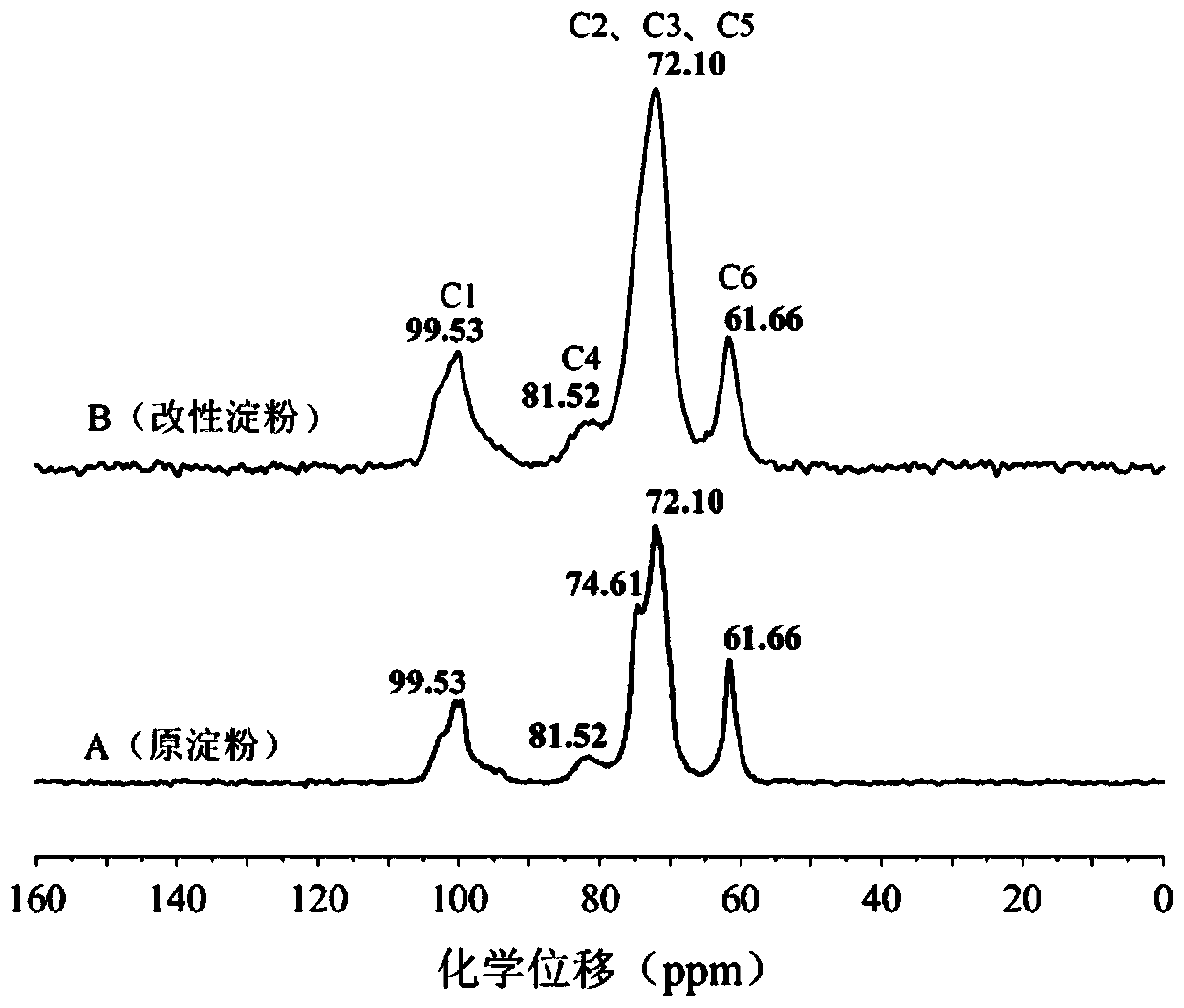

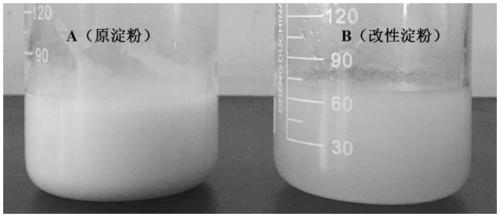

The invention discloses thermochemical modified starch, a preparation method and a method for preparing an adhesive by using the thermochemical modified starch and relates to modified starch and adhesives prepared by using the starch. The method is used for solving the technical problems of the existing starch adhesives that the water resistance is not ideal, the transportation cost is high, and the starch modification process is complicated. The thermochemical modified starch is prepared through uniformly spraying an acid solution into the starch, carrying out uniform mixing, then, carrying out heating treatment, carrying out baking, carrying out cooling, and then, carrying out crushing. The method for preparing the adhesive comprises the following steps: adding polyvinyl alcohol into a reactor pot with stirring, heating and cooling devices, adding water, adopting a staged-heating method to dissolve the polyvinyl alcohol with stirring, and then, cooling to room temperature; adding the thermochemical modified starch, carrying out stirring at room temperature, and then, adding polymethylene polyphenyl polyisocyanate, thereby obtaining the adhesive. According to the method, by using the technological characteristic that the starch-based adhesive is prepared by only adding the water to the thermochemical modified starch before use, the problem that the traditional solution type starch main agents are low in transportation efficiency and are prone to layering and mildewing is solved.

Description

technical field The invention relates to a modified starch and an adhesive prepared by using the starch, in particular to a starch-based adhesive used for waterproof plywood and the thermochemically modified starch. Background technique As the world's largest country in wood-based panel production, consumption and import and export trade, China's wood-based panel production has exceeded 322 million cubic meters in 2015. However, most of the adhesives used in my country's current wood-based panel production are still formaldehyde-based synthetic resins (mainly urea-formaldehyde resin adhesives and melamine-modified urea-formaldehyde resins). Products will release formaldehyde during manufacture, storage and use, and the issue of formaldehyde release from wood-based panels and the safety of the living environment have attracted more and more attention. Using starch, vegetable protein, lignin and other bulk biomass raw materials to prepare formaldehyde-free environmentally frie...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08B31/04C08B31/06C09J103/06C09J11/06

Inventor 高振华李舒野张冰寒顾继友张彦华

Owner NORTHEAST FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com