Characteristic self-learning device of universal exhaust gas oxygen sensor and using method of characteristic self-learning device

An oxygen sensor and self-learning technology, applied in machine/engine, fuel injection control, engine control, etc., can solve problems such as the inability to guarantee the authenticity of excess air coefficient measurement, achieve effective correction, prolong service life, and ensure authenticity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

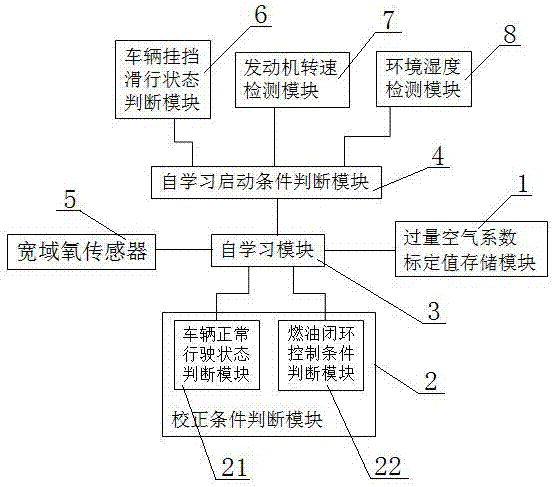

[0040] see figure 1 , a characteristic self-learning device of a wide-area oxygen sensor, comprising an excess air coefficient calibration value storage module 1, a correction condition judging module 2, a self-learning module 3, a self-learning starting condition judging module 4, and a vehicle gear sliding state judging module 6 , engine speed detection module 7, environmental humidity detection module 8, described correction condition judgment module 2 comprises vehicle normal driving state judgment module 21, fuel closed-loop control condition judgment module 22, described self-learning module 3 is used for correcting excess air coefficient, Its input end is electrically connected with the excess air coefficient calibration value storage module 1, the vehicle normal driving state judgment module 21, the fuel closed-loop control condition judgment module 22, the self-learning starting condition judgment module 4, and the output end of the wide-area oxygen sensor 5. The outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com