Connecting structure between rotating barrel and rotating joint of roller type drying equipment

A technology of rotating joints and rotating cylinders, which is applied in the field of connection structure between new rotating joints and drums, to achieve the effect of ensuring equipment, reliable operation and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

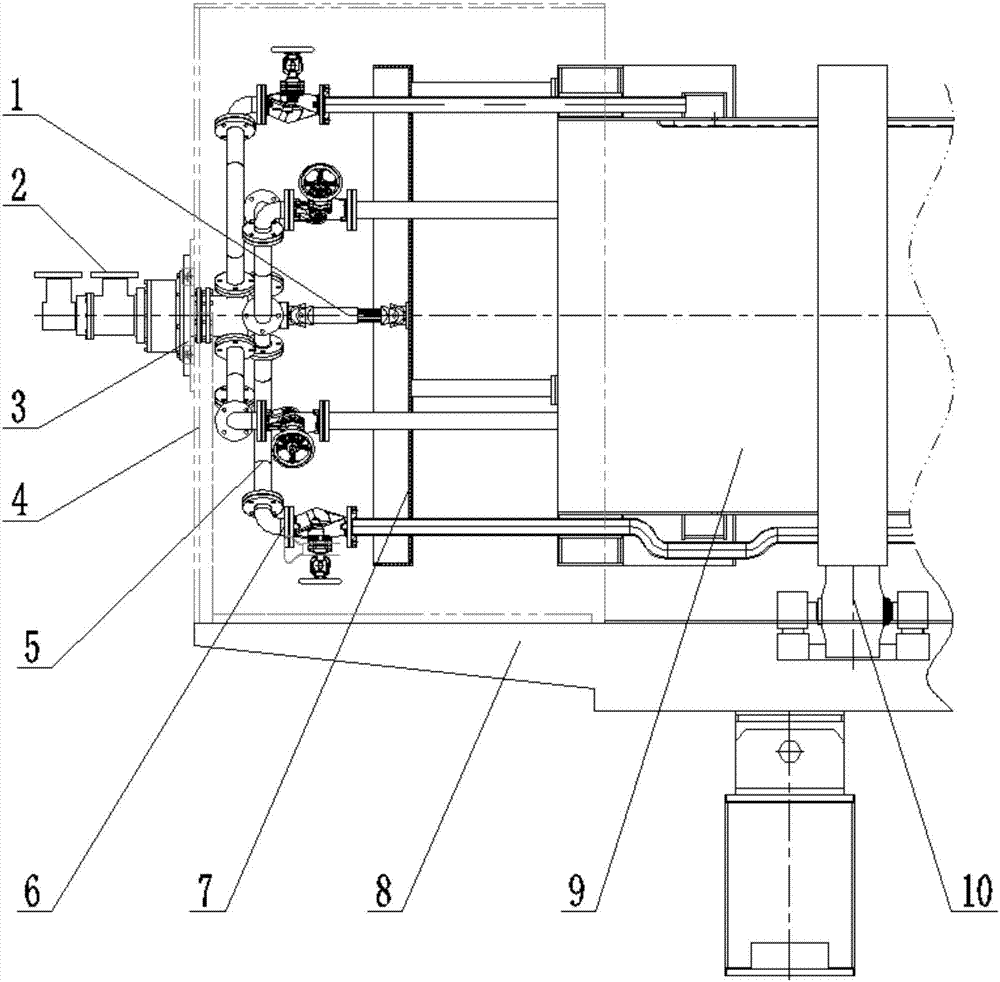

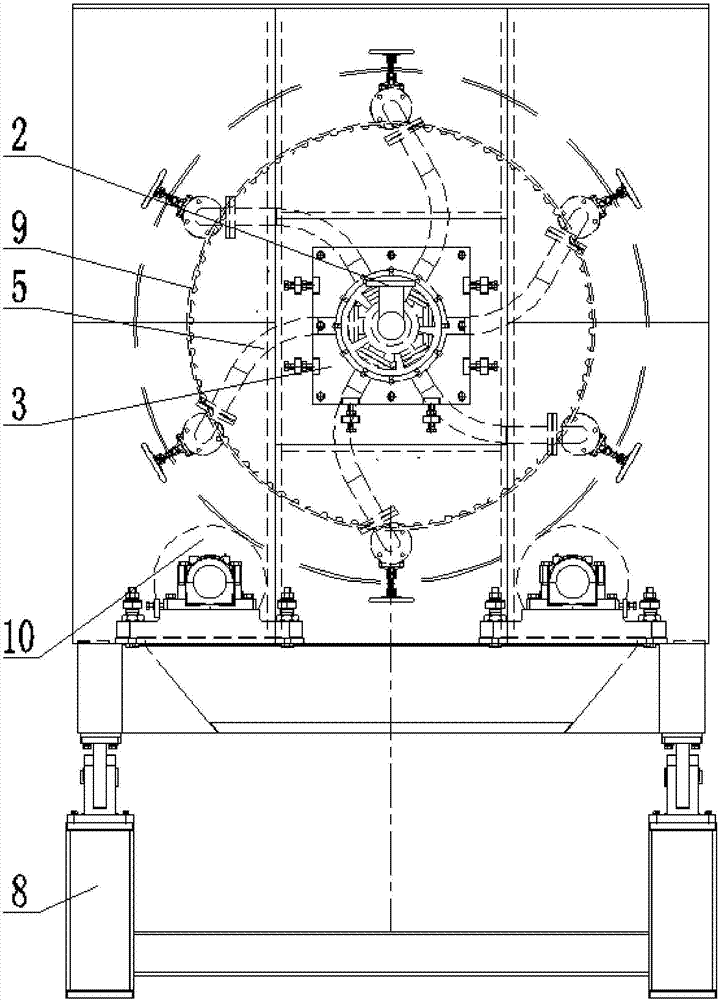

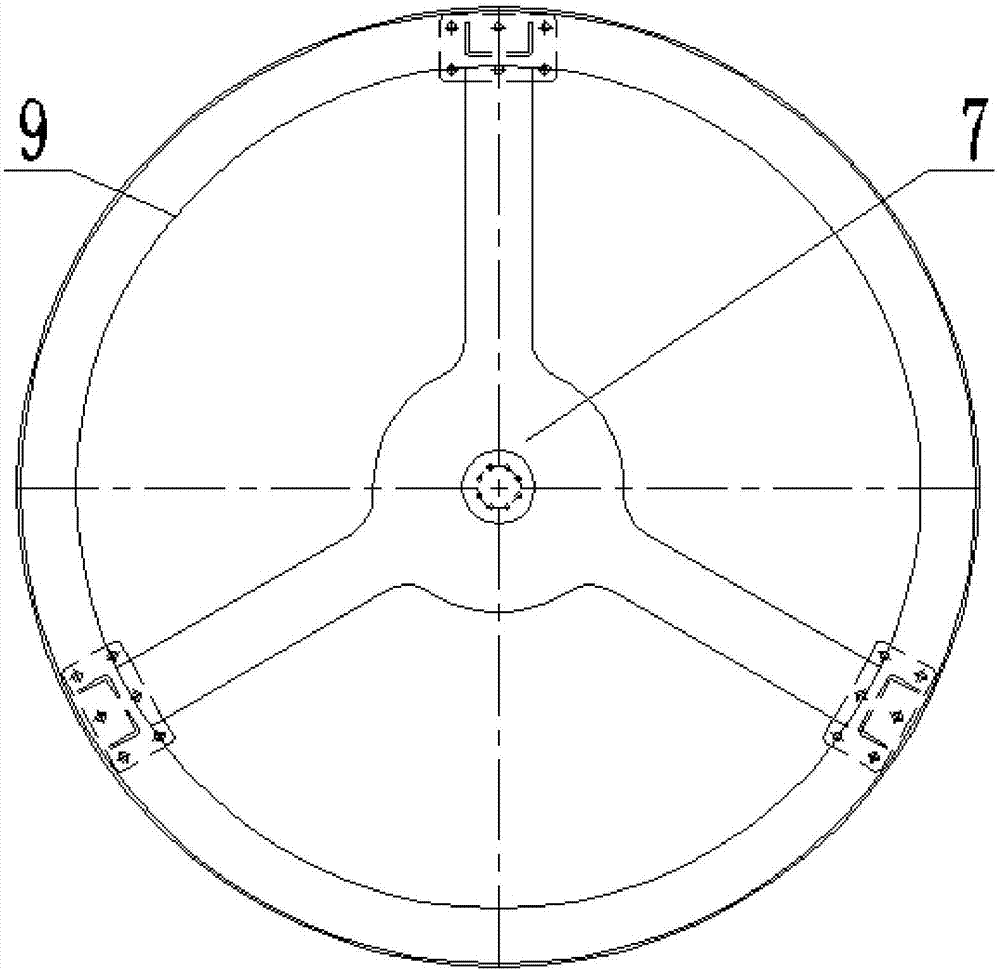

[0014] Such as figure 1 , 2 , 3, the high-stability, high-precision connection structure between the rotary joint 2 and the rotary cylinder 9 of the cylinder drying equipment provided by the present invention includes a universal joint 1, a translation adjustment plate 3, a rotary joint bracket (or Outer connecting plate of discharge cover) 4, medium conveying hose 5, medium conveying pipeline 6, end support 7, equipment support 8, etc.

[0015] The rotary joint 2 is fixedly installed on the side of the translation adjustment plate 3, and the translation adjustment plate 3 is installed on the side of the rotary joint bracket (or the connecting plate outside the discharge cover) 4, and the translation adjustment plate 3 can be connected on the rotary joint bracket (or the outer connection plate of the discharge cover) Plate) 4 moves, and the translation adjustment plate 3 is relative to the rotary joint bracket (or the outer connection plate of the discharge cover) 4, which ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com