Local constraint damping layer vibration test tool

A vibration test and restraint damping technology, applied in vibration testing, machine/structural component testing, measuring devices, etc., can solve problems such as unsatisfactory vibration transmission characteristics, high resonance peak amplitude, and insignificant effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

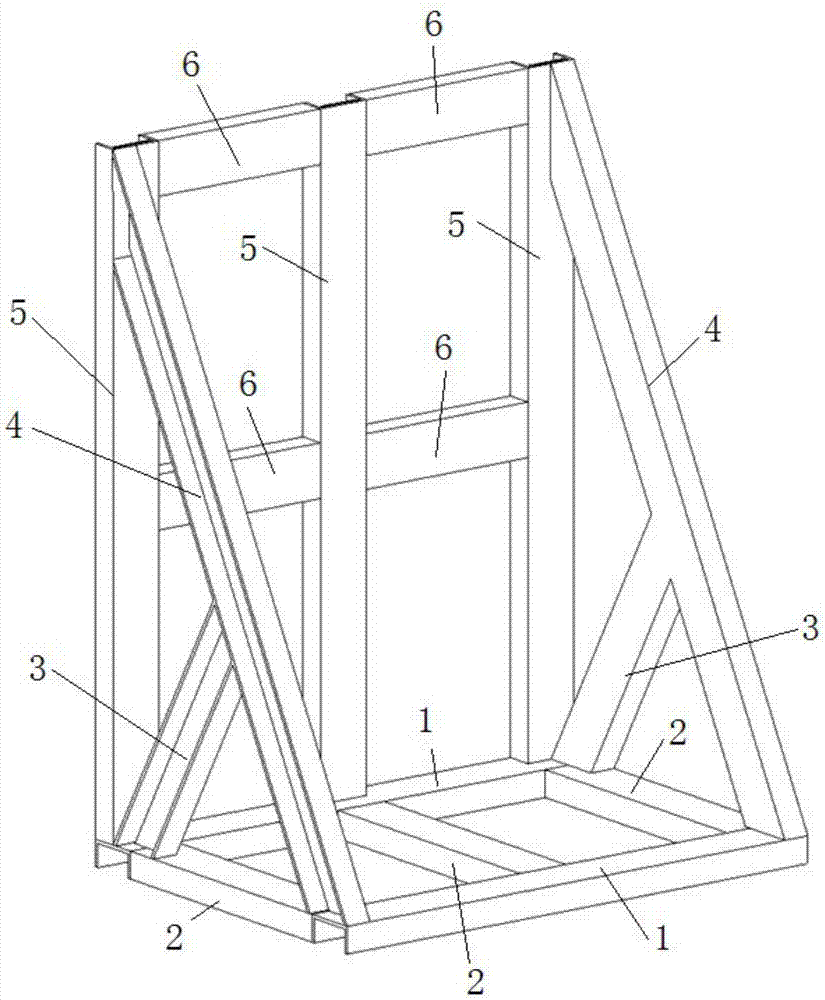

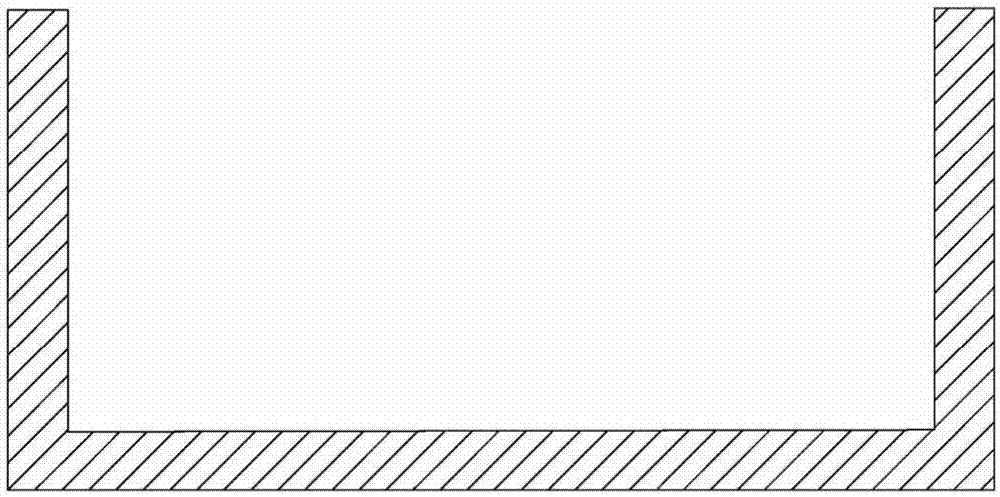

[0019] like figure 1 As shown, the vibration test tooling of traditional marine electromechanical equipment is simply composed of 2 first channel steels 1, 3 second channel steels 2, 2 third channel steels 3, 2 fourth channel steels 4, and 3 The fifth channel steel 5 and 4 sixth channel steels 6, a total of 16 channel steels are welded by continuous welding, the cross section of the channel steel is as follows figure 2 shown.

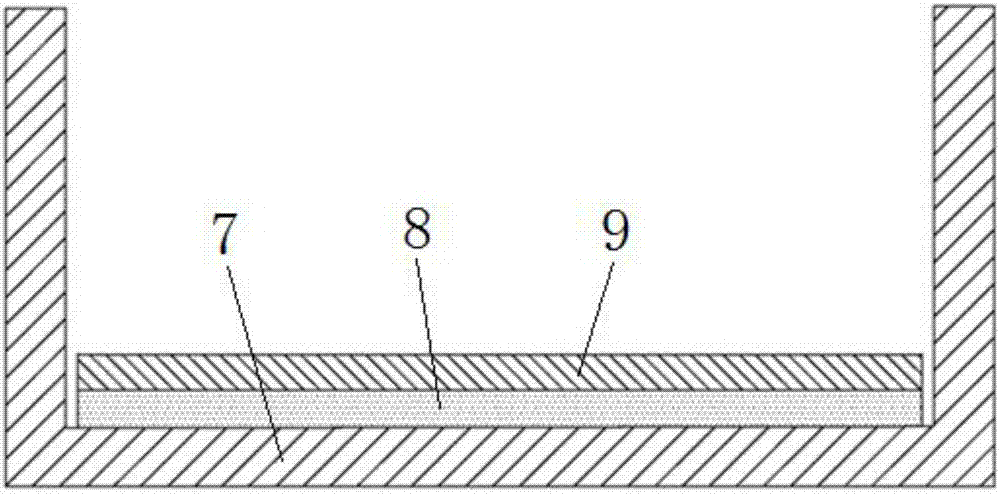

[0020] The local constrained damping layer vibration test tooling of the present invention is to install a single-layer constrained damping layer (such as image 3 shown) or multiple constrained damping layers (such as Figure 4 Shown), absorb the excess vibration energy on the tooling during the vibration test, especially the vibration component at the natural frequency of the tooling, so as to achieve the effect of suppress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com