Large-capacity electrochemical device individual structure and assembling method thereof

A single structure, electrochemical technology, applied in the direction of electrolytic capacitors, hybrid capacitor terminals, hybrid/electric double layer capacitor manufacturing, etc., to achieve the effect of simple production process, improved consistency, and easy automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

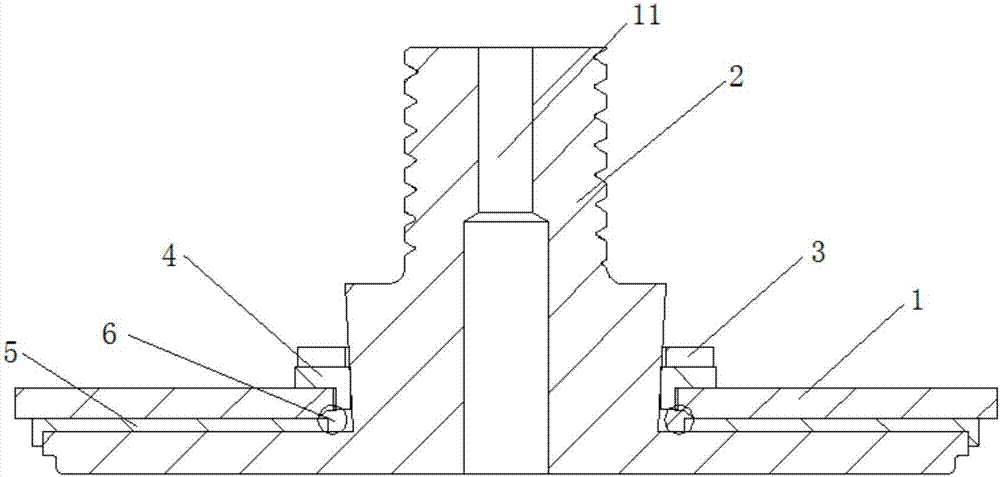

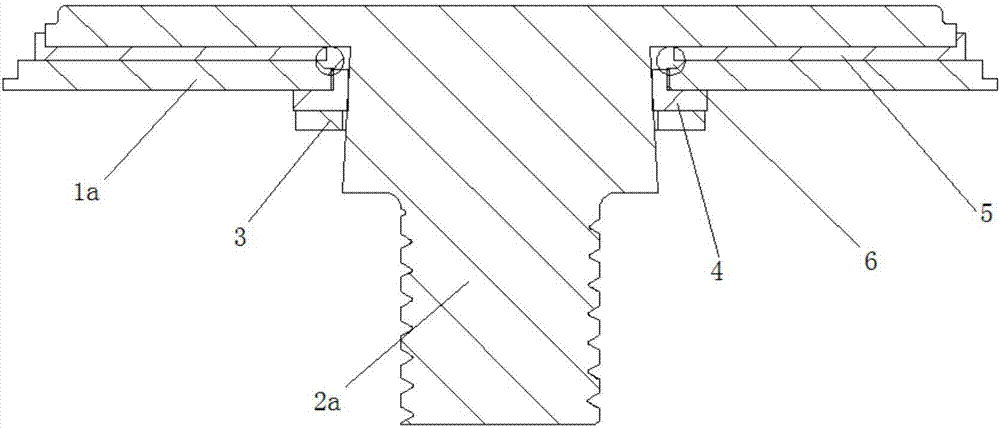

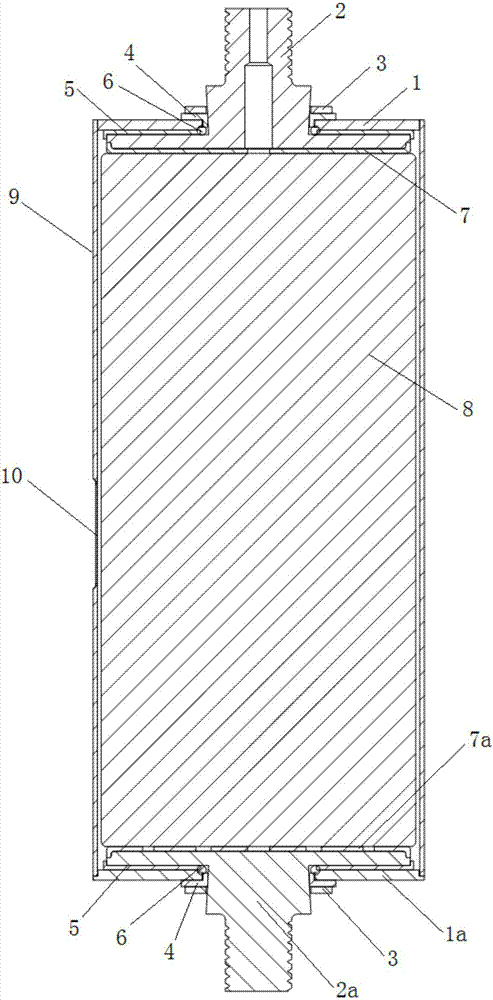

[0025] Such as figure 1 A single structure of a large-capacity electrochemical device is shown, including a positive aluminum pole 2, an aluminum can 9, a positive cover 1, a positive current collector 7, an electrode winding core 8, a negative current collector 7a, a negative cover 1a and a negative Aluminum pole 2a. Both ends of the electrode winding core 8 are respectively connected to the positive electrode current collector 7 and the negative electrode current collector 7a. The positive electrode current collector 7 and the negative electrode current collector 7a are respectively connected to the positive aluminum pole 2 and the negative aluminum pole 2a.

[0026] Such as figure 2 As shown, the positive aluminum pole 2 and the negative aluminum pole 2a are stepped columns. The positive cover plate 1 is set on the positive aluminum pole 2, an insulating ring 5 is arranged between the lower end surface of the positive cover plate 1 and the positive aluminum pole 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com