Cutters for internal burrs of straight seam steel pipes

A steel pipe and straight seam technology, which is applied in the field of pipe fitting cleaning equipment, can solve the problems of reducing the service life of steel pipes, reducing strength, and reducing the stability of steel pipes in use, so as to reduce the probability of stress fracture, strengthen support stability, and improve transportation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

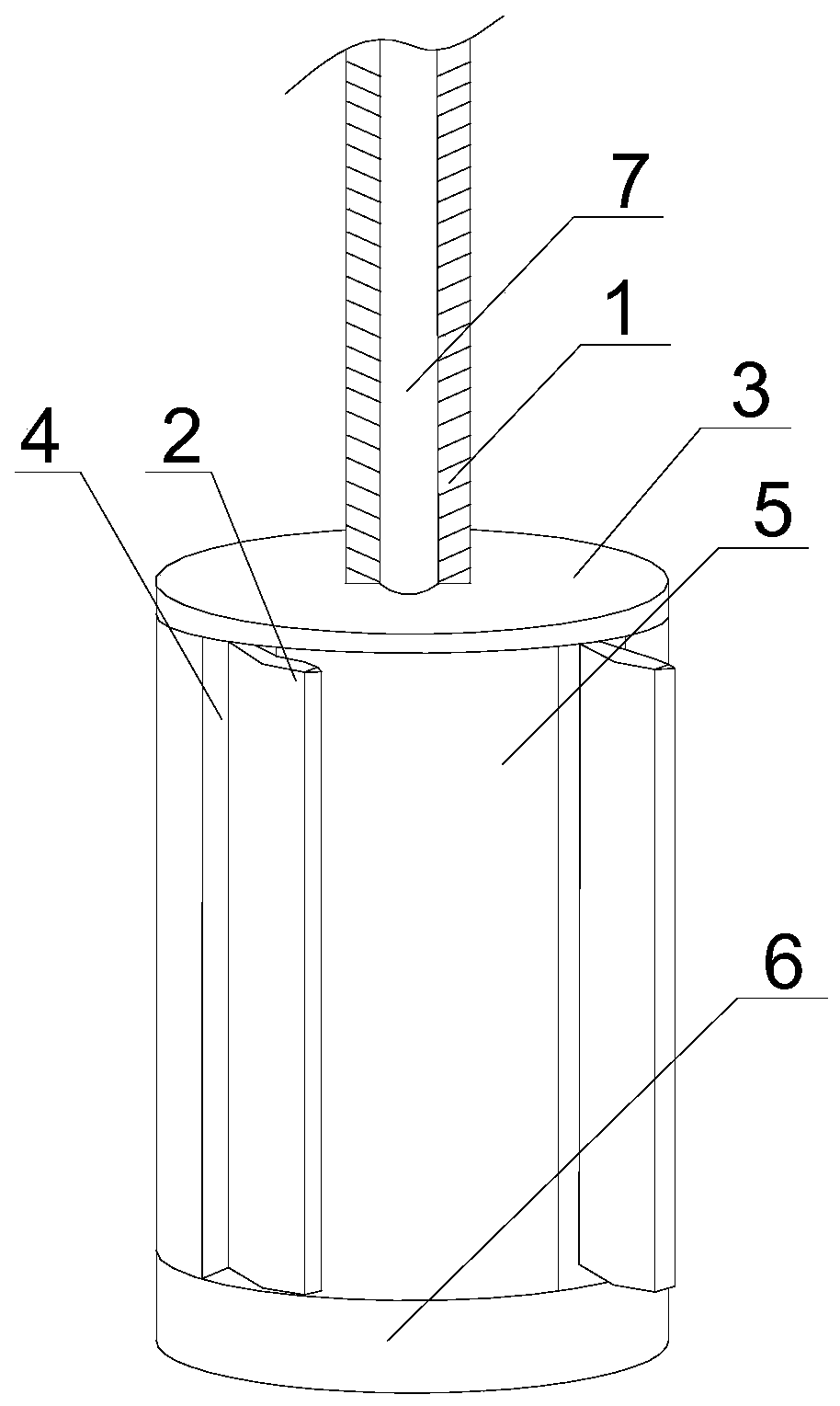

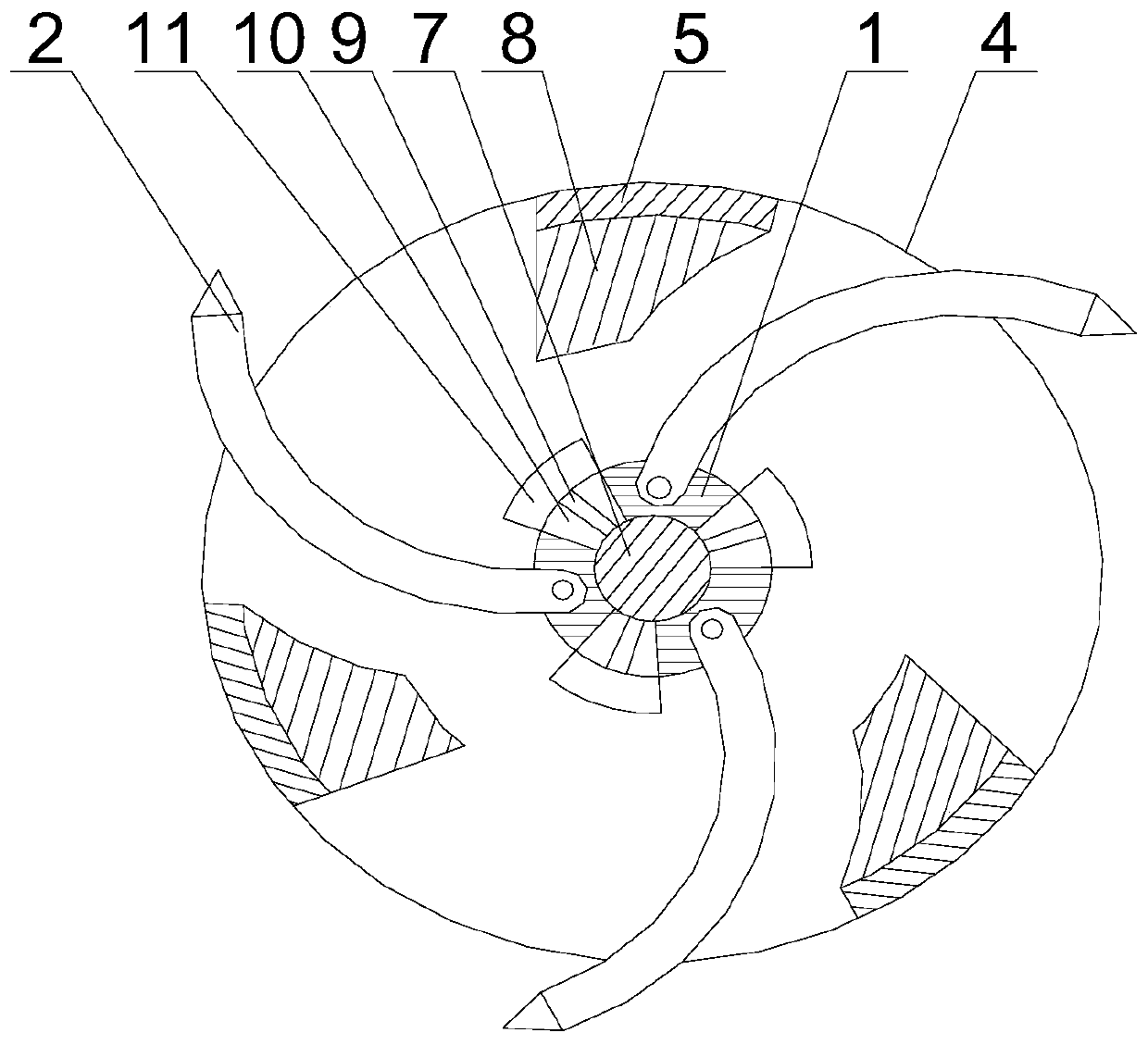

[0020] Such as figure 1 and figure 2 As shown, this embodiment includes a cylinder 5, a central shaft 1, a fixed plate 3 and a base 6, the fixed plate 3 seals the upper end of the cylinder 5 connected thereto, and the base 6 is fixedly connected to the lower end of the cylinder 5 A screw 7 is fixed in the middle of the upper surface of the base 6, the central shaft 1 moves through the middle of the fixed plate 3 and then extends downward, and a threaded through hole is opened in the middle along the axial direction of the central shaft 1, corresponding to the threaded through hole The matched screw rod 7 extends to the upper end of the cylinder body 5 after penetrating the threaded through hole, and a plurality of arc-shaped cutting pieces 2 are arranged on the central shaft 1, and a plurality of the cutting pieces 2 are hinged to the central shaft 1 and are evenly distributed on the On the outer peripheral wall of the central shaft 1, and along the radial direction of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com