Hand lay-up process and device used for process

A hand lay-up process and resin technology, applied in the field of hand lay-up process and its devices, can solve the problems of long molding cycle, high material cost, and many bubbles in the cloth layer, so as to reduce direct contact, improve the operating environment, reduce The effect of glue content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described by means of embodiments below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

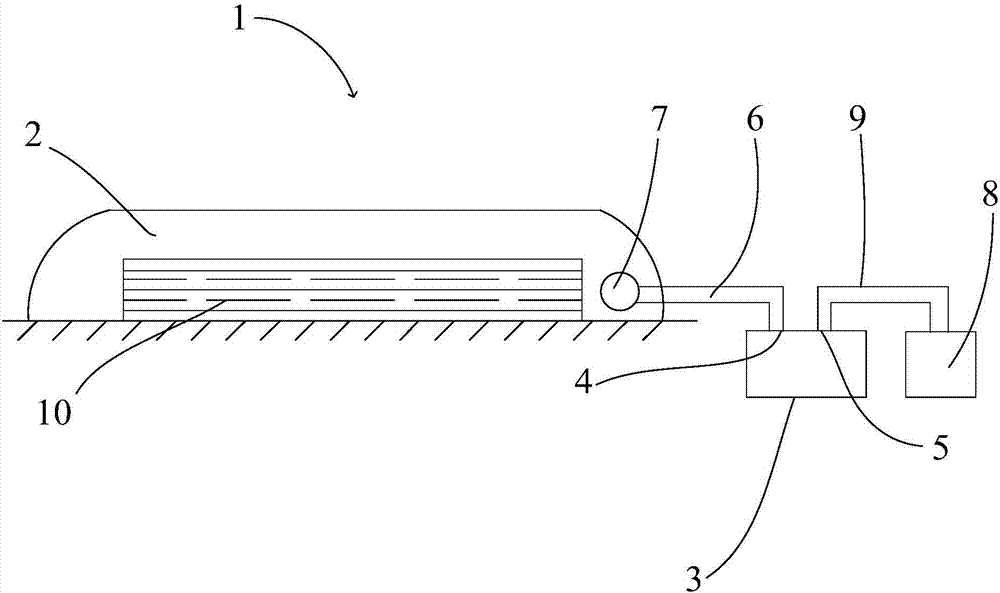

[0028] like figure 1 As shown, the device 1 for the hand lay-up process includes: a vacuum bag film 2, which has a diversion port 7; a resin receiver 3, and the top of the resin receiver 3 is provided with resin inflow ports 4 arranged at intervals And the air outlet 5, the resin inlet 4 and the air outlet 5 are all communicated with the inside of the resin receiver 3, the resin inlet 4 is connected with the guide port 7 through the first suction pipe 6; vacuum pump 8, the vacuum pump 8 is connected with this air outlet 5 through the second suction pipe 9.

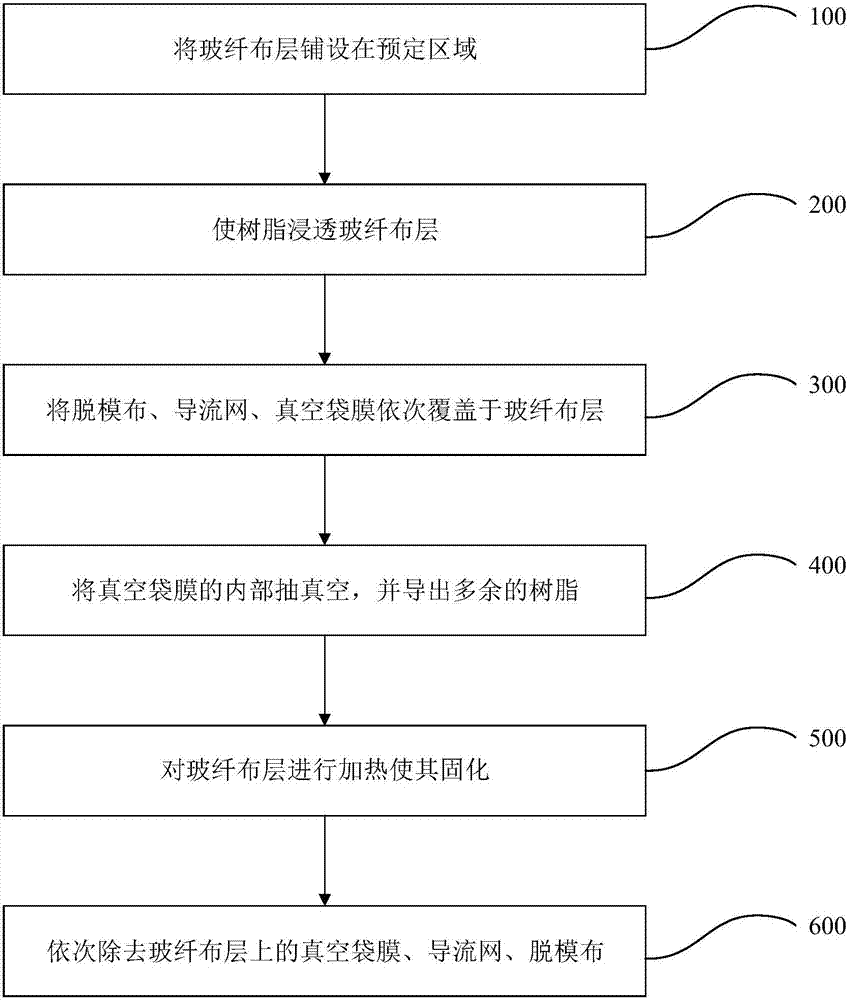

[0029] like figure 2 Shown, the hand lay-up process of the present embodiment comprises the following steps:

[0030] Step 100: laying the glass fiber cloth layer 10 on a predetermined area.

[0031] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com