Tyre type catapult-assisted take-off technique for aircraft

A technology of aircraft wheels and technology, which is applied in the direction of launching/dragging transmission devices, and can solve problems such as labor-intensive and time-consuming towing carts, and insufficient load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

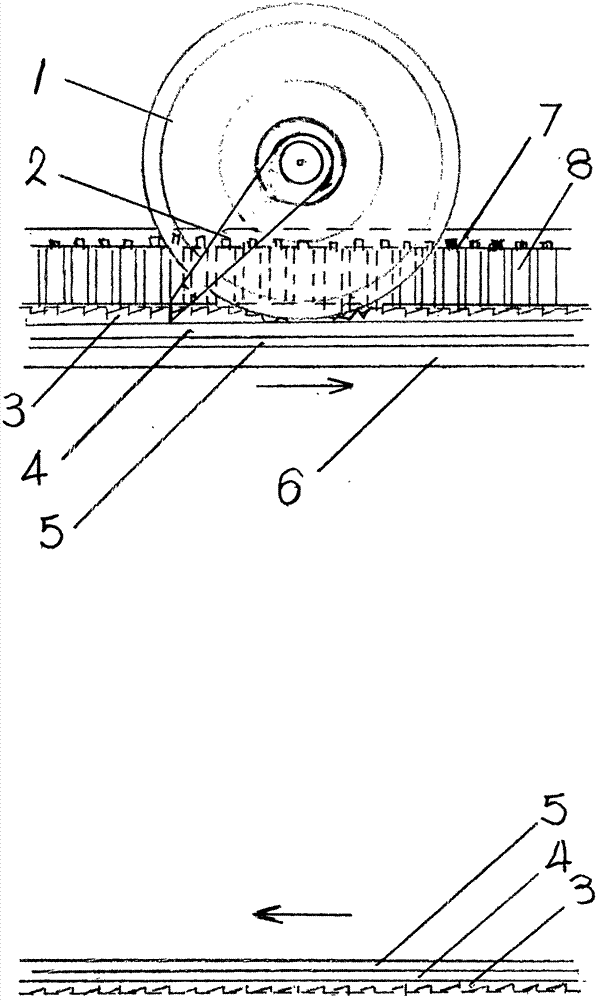

[0006] According to the structure and quality characteristics of the aircraft, select 1-3 coaxial active star gears and corresponding variable inertia flywheels, driven wheels, toothed belts, toothed belt groove covers, tensioning wheels, supporting pulleys, etc., the prime mover can be Equipped with an internal combustion engine or an electric motor, its electronic control system includes an aircraft wheel pressure belt sensor, a prime mover speed regulator, and a flywheel inertia regulator; the surface layer of the toothed belt star tooth layer 5 and the bottom surface layer of the toothed belt groove 6 are all slippery materials; The toothed belt groove cover plate 7 and the toothed belt groove 6 are unilaterally or split hinged. The toothed belt groove 6 is embedded in the ground of the runway. It is convenient for the aircraft to enter the take-off position one after another and accurately rush to the toothed belt. After the aircraft enters the take-off position, all the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com